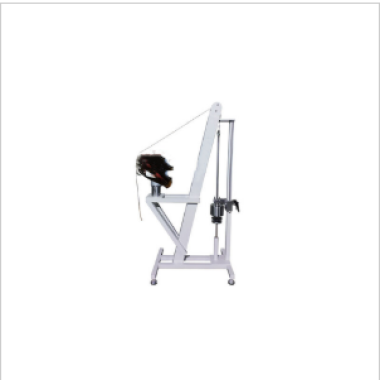

Catheter Burst Pressure Tester

The Catheter Burst Pressure Tester uses the positive pressure method and is designed according to the relevant clauses of Appendix F of YY0285.1-2017 and YY0285.4-2017. It is used to test the rated burst pressure (RBP) of the catheter, the balloon fatigue test without leakage or damage during filling, the balloon decompression time test, and the test of the relationship between filling diameter and filling pressure.

Applications

The catheter burst pressure tester is a key device used to evaluate catheter performance in the medical field. Its main uses include: Evaluating Catheter Pressure - Resistance Performance: By simulating high - pressure conditions in actual usage scenarios, gradually increasing the pressure applied to the catheter until it bursts, and recording the pressure at which the catheter bursts, the pressure - resistance performance of the catheter can be evaluated.

Quality Control: During the production process of catheters, the tester can be used in the quality - control process. It helps manufacturers conduct performance tests on each batch of catheters to ensure that every catheter meets the quality standards. Medical Device R & D: In the R & D stage of medical devices, the tester can be used to evaluate the performance of catheters made of different materials and with different design schemes in high - pressure environments, providing a basis for the optimized design of products.

Third - Party Testing and Certification: The tester is also widely used in third - party testing institutions and quality certification institutions, providing technical support for the certification and quality inspection of medical devices.

Standards

YY/T 1536-2017:Catheters other than intravascular catheters — Standard test model for evaluating the surface sliding performance

YY 0285.1-2017:Disposable sterile urinary catheters — Part 1: General requirements

Features

1. High-Precision Measurement: The tester employs high-precision pressure and flow sensors to accurately measure flow and pressure data during dynamic injection, ensuring reliable test results.

2. Real-Time Monitoring and Feedback: The tester features real-time monitoring capabilities, enabling timely detection of problems during injection, such as leaks or blockages, and providing corresponding feedback. This helps doctors or operators take timely measures to ensure patient safety.

3. Automated Operation: The tester utilizes an automated control system, simplifying the testing process, reducing human error, and improving testing efficiency and accuracy.

4. Flexibility and Adaptability: The tester is suitable for different sizes and types of intravascular catheters, meeting the needs of various dynamic injection scenarios. Furthermore, it can be customized to meet specific testing requirements.

Technical Parameters

| Technical Parameter | Specification |

|---|---|

| Testing Accuracy | With a high - precision measurement system, the error is generally not more than ±2%FS (full - scale error). This ensures the accuracy and reliability of the test results. |

| Testing Flow | Some testers may have the function of testing flow, and the flow range is generally 0 - 500ml or other applicable ranges. Flow testing helps evaluate the performance of catheters during power injection. |

| Water Bath Temperature | During the testing process, the water bath temperature is generally controlled at 37°C±1°C or 37°C±2°C to simulate the human body temperature environment. This helps ensure the accuracy and comparability of the test results. |

| Data Recording and Display | The tester should have a data - recording function and be able to store multiple groups of test data. Meanwhile, the test data should be presented in the form of charts or curves to enable users to intuitively understand the performance of catheters. |

| Automated Control | Some testers are equipped with automated control systems, which can automatically complete the testing process and reduce errors caused by human operations. This improves the testing efficiency and accuracy. |

Accessoriess

1. One main unit

2. Constant temperature bath: ambient temperature +8-99 degrees Celsius, temperature fluctuation ±1℃

3. One acrylic water tank, 1500mm in length

4. Luer connectors: 2 sets, including 1 male and 1 female connector

5. One instruction manual

6. One certificate of conformity

7. One power cord

8. One laptop computer (optional)

9. Metrology: One calibration certificate from a metrology institution.

Test Procedures

Precautions and safety precautions must be taken to protect test operators from the dangers of pressurization system failure and fluid leakage under high pressure.

1. Prepare the test catheter using clinically relevant pretreatments. For example, pre-soak in physiological saline, contact with commonly used injectable solutions, or sterilize.

2. Bring the chamber fluid temperature to (37±2)°C and maintain this temperature during the test.

3. Connect the catheter hub to the connector and secure it firmly with a locking device (if applicable).

4. Ensure that any gas inside the catheter has been expelled with fluid, then seal the catheter with clamps.

5. Check the hydraulic circuit for integrity and leaks.

6. Immerse the catheter in the circulating chamber fluid for at least 1 minute before the test to allow it to reach thermal equilibrium.

7. Adjust the hydraulic power source to supply fluid to the test catheter at a rate of 1 mL/s to generate sufficient pressure to cause the catheter to leak or burst. For alternative equipment, the manufacturer should select a pressure increment rate to control the test equipment, ensuring accurate measurement of the static burst pressure.

8. Inject fluid into the closed conduit until the conduit leaks or bursts.

9. While pressurizing the system, record the conduit seat pressure and note its maximum achievable pressure.

Send product request

Other supplier products

| Qinsun SUNTEST XXL+ | Qinsun SUNTEST XXL+is a large xenon lamp weathering and photoaging tester that complies with various ISO, ASTM, and ICH industry standards. The exp... | |

| STD Battery short-circuit tester | The Battery Short-Circuit Tester is designed for external short-circuit safety testing of lithium-ion batteries and battery packs. The system simu... | |

| Humidity Chamber | Features and Benefits 1. The humidity test chamber can realize long-term 85°C 85%RH test. The automatic water inlet and water circulation syst... | |

| Safety Helmet Roll-off Testing Equipment | The safety helmet retention test equipment is a device used to evaluate the stability of a helmet's fit when subjected to impact. By simulating the... | |

| Bag lifting fatigue testing machine | This machine is suitable for up and down vibration fatigue test of plastic handbag, garbage vest bag, kraft paper bag, woven bag and other bags bea... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |