10kN Universal Testing Machine

Standards:

1. Manufactured according to GB / T2611 "General Technical Conditions for Testing Machines" and GB / T 16491-2008 "Electronic Universal Testing Machine" standards; 2. Perform verification and acceptance according to GB / T12160 "Regulations for Extensometer for Uniaxial Test" and GB / T16825 "Inspection of Tensile Testing Machine" 3. Applicable standards: apply ASTM D5587, ASTM D5034 / D5035, DIN, ISO 13934-1, JIS, BS and other international standard

Applications:

The electronic universal testing machine is a classic and practical model developed by our company, and it is also the mainstream model currently produced.

Product Information:

The electronic universal testing machine is a classic and practical model developed by our company, and it is also the mainstream model currently produced. It was developed by our company after two new upgrade designs on the basis of previous generations of models based on Japanese technology. The structure of the mainframe and the measurement and control system have been greatly upgraded, the structure is more reasonable, and the functions are more complete. It is the leading technology in the industry. A new generation of electronic universal testing machine. This series of testing machines has been produced in a total of more than 1,000 units. After a large number of practical tests and continuous improvement, the technology and process are mature, the reliability is high, and the failure rate is low. It is well received and welcomed by the market and users.

Product Structure Function

1. The testing machine has no pollution, low noise, convenient operation and high efficiency;2. The mainframe shell is made of aluminum alloy shell, which is beautiful and generous;

3. The main unit is an overall floor-standing vertical structure, with high rigidity, stable performance and beautiful appearance;

4. Stretching and compression are realized in separate double spaces, avoiding the tediousness of replacing different test attachments in the same space;

5. The mainframe structure is sturdy and durable. The thick ball screw and guiding light rod, thickened beam and base constitute a strong rigid frame, which can meet the test of high-strength materials

6. The upper and lower beams of the main machine and the worktable are processed synchronously to ensure excellent alignment. During the axial test, to ensure that the lateral force of the sample under the load is minimally affected, and accurate stress and strain results can be obtained;

7. The screw is a precision ground ball screw imported from Taiwan, and the screw nut is made of cast copper material, which is wear-resistant. The friction coefficient of the screw pair is small, the transmission efficiency is high, the precision is high, and the strength is high;

8. The reduction mechanism composed of a reducer, a synchronous toothed belt, and a precision ball screw pair has a simple structure to ensure the synchronous movement of the screw and help the system to center;

9. High-power motors with reserve power, pre-loaded bearings, low-tension synchronous toothed belts, and precision ball screw pairs can minimize the energy stored during the test process, resulting in better test performance and better performance. For precise modulus and strain values. It is particularly effective when testing high-strength materials, such as aerospace composite materials and metal alloys; Using AC servo motor and speed control system to control the test process, the control accuracy is high, stable, efficient, and low noise (basically no noise at low speed). And the control speed range is greatly widened, which is not only conducive to the low-speed test of conventional materials (metal, cement, concrete, etc.), but also to the high-speed test of non-metallic materials (rubber, film, etc.), and it is also convenient for quick adjustment when there is no load. Test space, save auxiliary test time. The test speed meets the current requirements for the test speed of all conventional metal and non-metal materials in China;

Send product request

Other supplier products

| Automatic voltage internal resistance tester | Standard ASTM E83: Standard Test Method for Verification of Linear Displacement Measuring Systems ISO 3611: Calibration of Measuring Instruments ... | |

| Safety Helmets Against Molten Metal Splashing Tester | Standard GB/T 2812-XXXX: Safety Helmets – Test Methods for Molten Metal Resistance (Draft Standard) GB 2811-2019: Head Protection –... | |

| Large diameter blasting test machine | Standard ASTM D1599: Compliant for short-time hydraulic failure testing of thermoplastic pipes under linear pressure ramp. ISO 1167: Configurable... | |

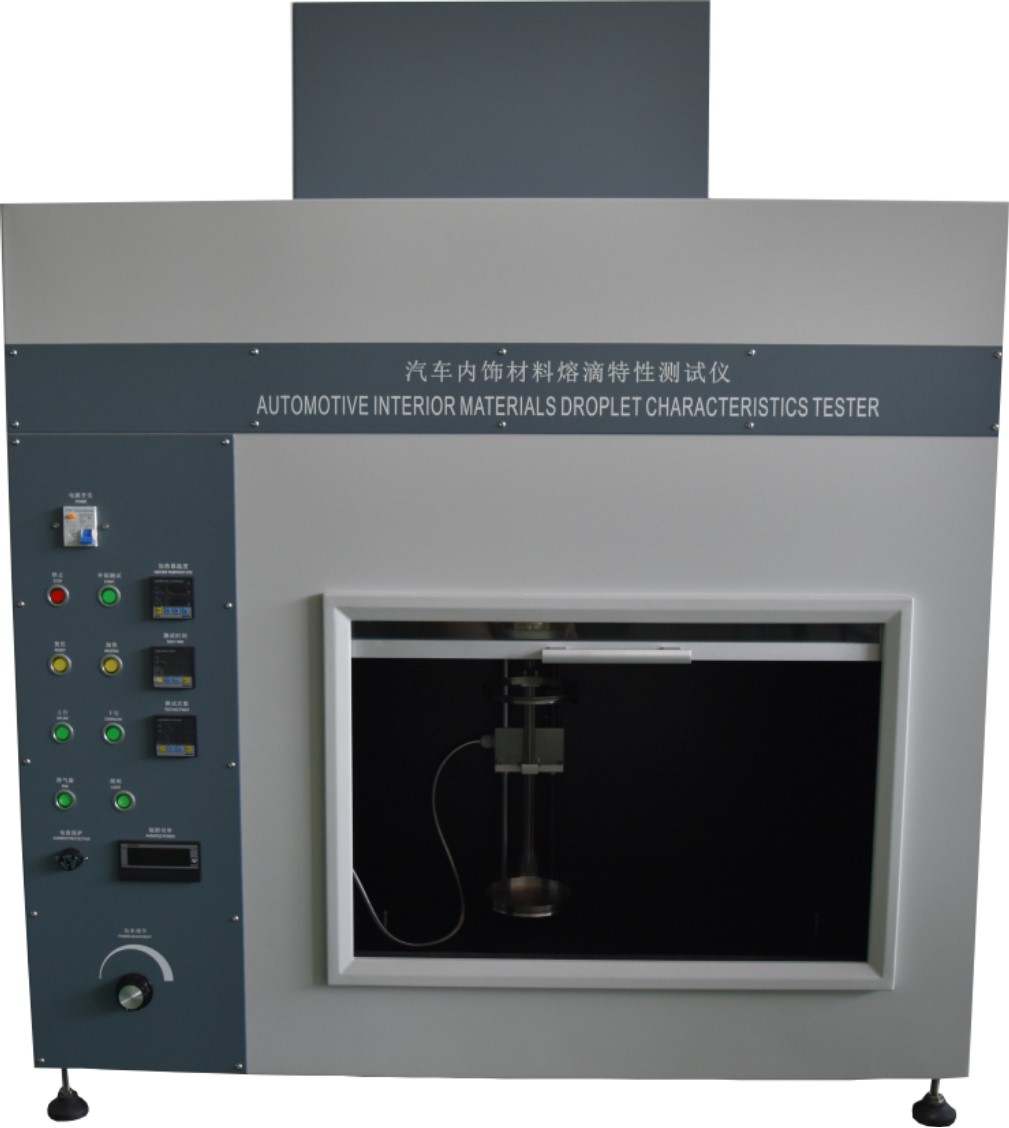

| Automotive Interior Materials Droplet Characteristics Tester | Standards: 1. 1995L0028-EN-01.01.2007-002.001-25 ( ANNEX V) Measurement method of melting properties. 2. NF P92-505 Dripping test with electrical ... | |

| Battery diaphragm permeability tester | Meet the standard: GB/T458, ISO536/2, QB/T1667, GB/T23227, ISO2965, YC/T172, GB/T12655, S05636/3, IS05636/5, GB/T20042.7-2014, GB/T36363-2018, ... |

Same products

| Falling Sand Abrasion Test machine | Seller: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | Seller: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | Seller: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | Seller: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... | |

| High temperature vacum friction & wear tester | Seller: Standard International Group (HK) Limited | The working principle of a high-temperature vacuum friction and wear testing machine is to simula... |