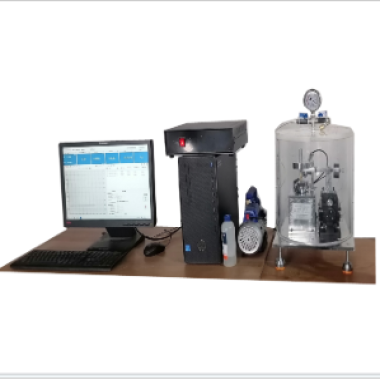

Automatic voltage internal resistance tester

The Automatic Voltage & Internal Resistance Tester is a precision electrical testing instrument designed for rapid and accurate measurement of open-circuit voltage (OCV) and DC internal resistance of lithium-ion battery cells. The system is widely used in battery research laboratories, production lines, and quality control departments to evaluate electrical consistency, detect defective cells, and support battery performance classification and safety assessment.

Application

(1) Open-circuit voltage (OCV) measurement of lithium-ion pouch cells, cylindrical cells, and coin cells.

(2) DC internal resistance measurement for cell grading and sorting.

(3) Incoming inspection of battery cells and semi-finished products.

(4) Quality control during cell production, formation, and aging processes.

(5) Electrical consistency evaluation for batch comparison and statistical analysis.

(6) Screening of abnormal cells with high internal resistance or voltage deviation.

(7) Laboratory research and process validation for battery development.

Standards

(1) IEC 62660-2 – Secondary Lithium-Ion Cells – Reliability and Abuse Testing (reference application).

(2) ASTM E83 – Verification of Linear Displacement Measuring Systems (instrument calibration reference).

(3) ISO 3611 – Verification of Linear Measuring Instruments (instrument calibration reference).

(4) RoHS – Restriction of Hazardous Substances Directive.

(5) CE Certification – Conformité Européenne.

Features

(1) Simultaneous measurement of voltage and internal resistance with high accuracy.

(2) Automated test sequence reduces operator influence and improves repeatability.

(3) Fast measurement suitable for production-line and batch testing.

(4) Wide compatibility with pouch, cylindrical, and coin-type battery cells.

(5) Stable contact design ensures reliable electrical connection.

(6) Built-in data storage and result classification functions.

(7) Digital communication interface for data export and system integration.

(8) Electrical safety protection with overload and short-circuit prevention.

Technical Parameters

| Parameter | Specification |

|---|---|

| Voltage Measurement Range | 0 – 10 V |

| Voltage Measurement Accuracy | ±0.05% F.S |

| Internal Resistance Range | 0.01 mΩ – 1,000 mΩ |

| Internal Resistance Accuracy | ±0.5% F.S |

| Measurement Method | DC pulse method |

| Measurement Time | ≤ 1 s per cell |

| Data Storage | ≥ 100,000 records |

| Communication Interface | USB / RS232 / Ethernet (optional) |

| Power Supply | AC 100–240 V, 50/60 Hz |

| Dimensions (W×D×H) | 300 × 250 × 400 mm |

| Weight | 15 kg (net) / 18 kg (gross) |

Accessories

(1) Battery test fixture for pouch, cylindrical, and coin cells.

(2) Kelvin test leads and probe assemblies.

(3) Calibration resistor set for internal resistance verification.

(4) Data acquisition and analysis software.

(5) Power cables and grounding accessories.

(6) Operation and maintenance manual.

(7) Compliance and calibration certificates.

Test Procedure

(1) Power on the tester and allow system self-check.

(2) Perform calibration using certified voltage sources and standard resistors.

(3) Place the battery cell into the appropriate test fixture.

(4) Ensure correct polarity and stable electrical contact.

(5) Start the test sequence to measure voltage and internal resistance.

(6) Display, store, and export the test results as required.

Maintenance Information

(1) Keep test probes and fixtures clean to ensure stable contact resistance.

(2) Periodically verify measurement accuracy using standard resistors.

(3) Inspect cables and connectors for wear or damage.

(4) Avoid exposure to corrosive gases, electrolyte leakage, or high humidity.

(5) Store the instrument in a clean and temperature-controlled environment when not in use.

Send product request

Other supplier products

| Model Coin-cell Swelling System | The Model Coin-Cell Swelling System is designed for in-situ measurement of thickness and volume changes of coin-type lithium-ion cells during charg... | |

| Plastic Friction and Wear Tester | Product Description: Plastic sliding friction wear tester consists of two main parts: the host machine and intelligent control system, which can b... | |

| Vacuum Ball - Disk Friction Tester | A vacuum ball-on-disk friction tester is a device used to simulate friction and wear behavior under actual operating conditions, in order to evalua... | |

| Liquid Auto-Ignition Temperature Tester | Product Description complies with GB/T 21860-2008 “Test Method for Autoignition Temperature of Liquid Chemicals” and ASTM E “Tes... | |

| Pipe Coating Scratch Resistance Tester (for Pipe coating scratch tester) | Product Introduction: Paint and varnish scratch resistance tester, also known as scratch resistance tester or balanced scratch rod adhesion resist... |

Same products

| Falling Sand Abrasion Test machine | Seller: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | Seller: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | Seller: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | Seller: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... | |

| High temperature vacum friction & wear tester | Seller: Standard International Group (HK) Limited | The working principle of a high-temperature vacuum friction and wear testing machine is to simula... |