PV Hail Impact Tester

The PV Hail Impact Tester is a precision instrument designed to evaluate the mechanical resilience of photovoltaic modules under simulated hail impact conditions. It delivers controlled and repeatable impact energies to assess module durability, ensuring compliance with international IEC, UL, and ASTM standards. The system supports both laboratory testing and quality control in production lines, providing high-speed imaging and automated data logging for comprehensive performance analysis.

Application

The tester is suitable for:

Quality control of photovoltaic modules during production.

R&D for new PV module designs and materials.

Verification of hail resistance under extreme weather conditions.

Certification testing in compliance with IEC, UL, and ASTM standards.

Standards

IEC 61215: Mechanical load testing for terrestrial photovoltaic modules

UL 61730: Safety standards for photovoltaic modules under extreme weather conditions

ASTM E1886: Impact resistance testing for building envelopes (adapted for PV applications)

IEC TS 63057: Hail impact simulation protocols for concentrated solar power systems

Features

Precision Engineering: High-speed pneumatic system with ±2% accuracy delivers consistent impact energies.

Adjustable Simulation: Ice ball diameter adjustable from 25 mm to 75 mm to simulate diverse hail sizes.

Safety Assurance: Enclosed chamber with transparent polycarbonate shielding, emergency stop, and over-pressure protection.

User-Friendly Operation: 7” touchscreen HMI with multi-language support and pre-programmed test modes.

High-Speed Imaging: 1000 fps camera captures impact dynamics for post-test analysis.

Automated Control: Programmable ice ball trajectory (0°–90°) and real-time force, velocity, and deformation data logging.

Robust Construction: Stainless steel frame with anti-vibration mounts and low-noise operation (<65 dB).

Customizable: Optional environmental chamber (-40°C to +85°C) for temperature-dependent impact testing.

Parameters

| Parameter | Specification |

|---|---|

| Impact Energy Range | 0.5 J – 50 J (adjustable) |

| Ice Ball Diameter | 25 mm, 35 mm, 50 mm, 75 mm |

| Test Temperature Range | -40°C to +85°C (with optional environmental chamber) |

| Sample Size | Max. 2200 mm × 1400 mm (dual-station) |

| Power Supply | 220V/380V, 50/60Hz, 3-phase |

| Air Compressor Requirement | 0.6–0.8 MPa, 1.2 m³/min |

| Dimensions (L×W×H) | 3500 mm × 2000 mm × 2500 mm |

Accessories

Impact Materials: 100x ice balls (25 mm/35 mm/50 mm/75 mm mix)

Sample Clamping Kit: Adjustable for frameless or framed PV modules

Software Suite: Real-time data acquisition and analysis tool, report generator (PDF/Excel export)

Spare Parts Kit: 2x pneumatic nozzles, 5x O-rings, 1x calibration tool

User Manual: Multilingual printed and digital copy

Test Procedures

Install PV modules securely in the dual-station clamps.

Select ice ball size and impact energy through the touchscreen HMI.

Set test parameters, including trajectory angle (0°–90°) and optional environmental temperature.

Initiate the automated impact sequence.

Monitor high-speed camera footage and real-time data logging for force, velocity, and deformation.

Review test reports and export results for documentation or certification purposes.

Maintenance Information

Inspect ice ball launcher, pneumatic nozzles, and clamps before each test session.

Clean the testing chamber and polycarbonate shielding regularly to ensure visibility and safety.

Check and replace O-rings, pneumatic fittings, and ice balls as needed.

Ensure air compressor delivers stable pressure within 0.6–0.8 MPa.

Periodically calibrate sensors and high-speed imaging equipment according to manufacturer guidelines.

Send product request

Other supplier products

| Mechanical load testing machine for photovoltaic modules | The Mechanical Load Testing Machine for Photovoltaic Modules is engineered to evaluate the mechanical durability of both crystalline and thin-film ... | |

| Building material products single combustion tester | Product Information Single Burning Items(SBI), as a European evaluation of the fire-resistance performance of building materials, measures heat ... | |

| Rubber Mooney viscometer | Test principle: The Mooney viscometer is used to measure the viscosity of rubber under specific conditions. In the test, the rubber sample was loa... | |

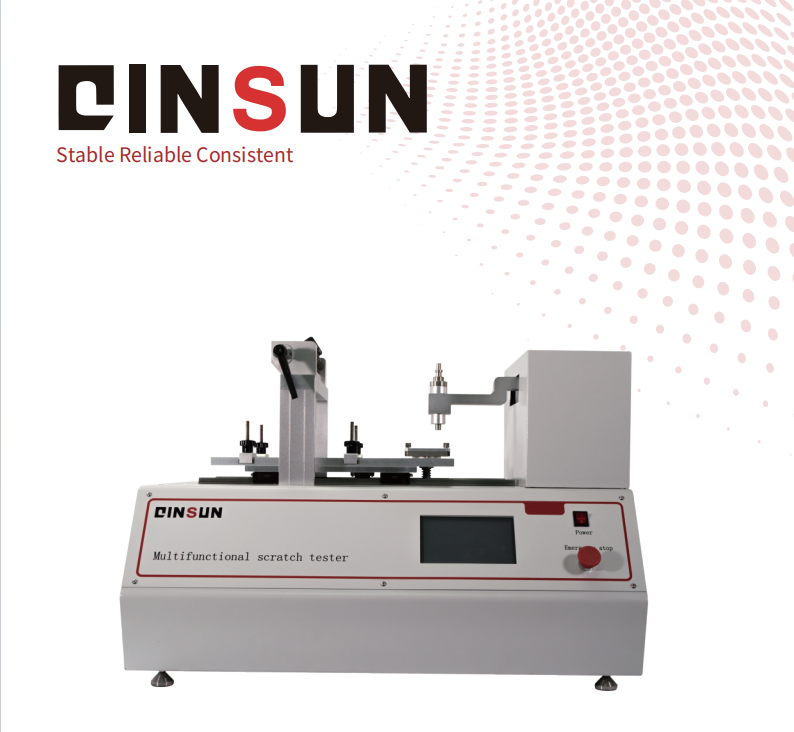

| Multi-function Scratcher | Application It is suitable for testing automotive interior materials, plastics, rubber, leather, coated fabrics, coating materials, composite mate... | |

| Full Notch Creep Tester | Standard ISO 16770: Exclusively designed for full-notch creep testing (FNCT) of thermoplastics under sustained stress. ASTM D2990: Configurable f... |

Same products

| Falling Sand Abrasion Test machine | Seller: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | Seller: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | Seller: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | Seller: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... | |

| High temperature vacum friction & wear tester | Seller: Standard International Group (HK) Limited | The working principle of a high-temperature vacuum friction and wear testing machine is to simula... |