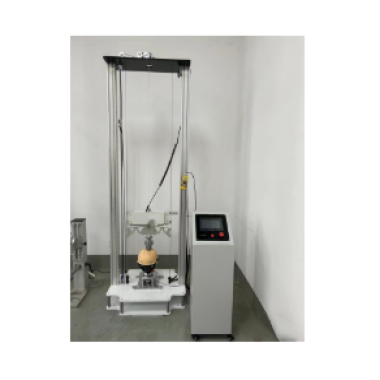

Safety Helmets Impact and Penetration Resistance Tester

The Safety Helmets Impact and Penetration Resistance Tester is a dual-function testing system designed to evaluate helmet safety under both impact and penetration conditions. It ensures compliance with national and international standards, supporting quality control, certification testing, and research applications.

Application

(1) Impact resistance testing for industrial helmets (e.g., construction safety helmets, GB/T 2812 certified)

(2) Impact testing for cycling helmets (road, mountain, BMX)

(3) Impact testing for motorcycle helmets (full-face, modular, open-face)

(4) Penetration resistance testing for climbing helmets and rope-access helmets

(5) Custom helmet testing for sports or military applications

(6) R&D and batch quality control for OEM helmet lines (including EN 960 S/M/L headforms)

(7) Certification testing for GB/T 2811-2019, ISO 6220-2, and CE/EN compliant helmets

Standards

(1) GB/T 2811-2019 – Helmet safety and impact resistance

(2) GB/T 2812-2006 – Testing methods for impact absorption and penetration resistance

(3) ISO 6220-2 – Road vehicles restraint systems energy absorption test methods

(4) EN 960 – Headforms for protective helmet testing

(5) CE Certification (Conformité Européenne)

Features

(1) Dual-Function Versatility: Rapid fixture exchange allows switching between impact and penetration tests in under 10 minutes

(2) Ultra-Precision Impact Analysis: 5 kg hemispherical hammer with 1,000 mm drop height and 20,000 N force sensor at 0.1 N resolution

(3) Penetration Resistance Validation: 3 kg conical tip hammer (60° ±0.5°, 40 mm min., 45–50 HRC) simulating sharp object impacts

(4) Smart Data Acquisition: Real-time force curves with pass/fail alerts and 1 ms resolution

(5) Industrial Durability: 4 m steel frame with anti-vibration design, IP65-rated control panel

(6) Safety Systems: Light curtain, energy-absorbing base, and emergency stop

(7) Universal Compatibility: EN 960 headforms (S/M/L) and custom 3D-printed headforms for specialized helmets

Parameters

| Specification | Impact Test | Penetration Test |

|---|---|---|

| Drop Height | 1,000 ±5 mm | 1,000 ±5 mm |

| Hammer Weight | 5.0 ±0.1 kg | 3.0 ±0.05 kg |

| Tip Geometry | Hemisphere (R50 ±1 mm) | Cone (60° ±0.5°, 40 mm min.) |

| Force Sensor | 20,000 N, 5 kHz sampling | N/A (mechanical stop) |

| Data Resolution | 0.1 N | 0.1 mm displacement |

| Frame Height | 4,000 mm | 4,000 mm |

| Power Requirements | 220V/110V AC, 50/60Hz, 800 W | 220V/110V AC, 50/60Hz, 800 W |

Accessories

(1) Headform Kit: EN 960 S/M/L sizes with polyurethane skin coating

(2) Hammer Set: Impact (5 kg) and penetration (3 kg) hammers with storage case

(3) Calibration Tools: NIST-traceable force gauge and Rockwell hardness tester

(4) Safety Kit: Light curtain, energy-absorbing base mat, emergency stop button

(5) Software License: HelmetImpact Pro, cloud-connected with API integration for QMS systems

(6) Installation & Training: On-site setup by certified engineers, 16-hour virtual operator training

Test Procedures

(1) Install the helmet on the selected headform.

(2) Select impact or penetration test mode and attach the corresponding hammer.

(3) Set drop height, test parameters, and safety interlocks via the HMI.

(4) Conduct the test; monitor real-time force/displacement curves.

(5) Record peak forces and penetration measurements; evaluate against standard requirements.

(6) Generate automated pass/fail reports and export data for QC or certification.

Maintenance Information

(1) Inspect hammers, headforms, and force sensors regularly for wear or damage.

(2) Clean frame, rails, and fixtures with non-corrosive solution.

(3) Verify calibration of force sensors and drop heights periodically.

(4) Lubricate linear bearings and moving components as per schedule.

(5) Store in a clean, dry environment to maintain precision and service life.

Send product request

Other supplier products

| Safety Helmets Acceleration Impact & Penetration Tester | The Safety Helmets Acceleration Impact & Penetration Tester is a dual-mode testing instrument designed to evaluate helmet performance under bot... | |

| Single - Strand Bending Tester STD - FB2 - SH | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to easily measure and quantify softness, elasticity, ... | |

| Infusion device Leakage negative pressure tester | The Infusion Device Leakage Negative Pressure Tester is designed to evaluate the airtightness of syringes, infusion sets, and related medical devic... | |

| Scratch tester STD-KK02 | Product introduction: With the continuous expansion of the use of plastic molding products, from the point of view of the surface appearance of mo... | |

| Helmets Designated Protection Areas Tester | Main Purposes 1. Used to mark test points and test lines on helmets. 2. Used for line - marking according to different test standards. 3. Used t... |

Same products

| Falling Sand Abrasion Test machine | Seller: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | Seller: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | Seller: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | Seller: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... | |

| High temperature vacum friction & wear tester | Seller: Standard International Group (HK) Limited | The working principle of a high-temperature vacuum friction and wear testing machine is to simula... |