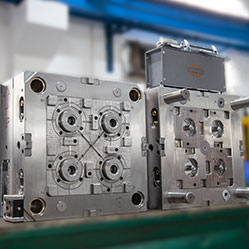

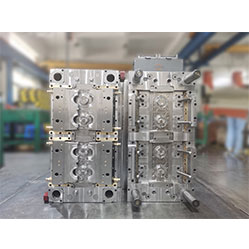

Gas & Water Assisted Injection Mold

Gas Assist Injection Molding Design Guide

Since the thermal conductivity and heat capacity of water are much bigger than nitrogen, so the injection cycle of water-assisted is about 70% shorter than the injection cycle ofgas assist molding; The product wall thickness of water-assisted injection molding is more even than gas-assisted; The inner wall roughness of water-assisted injection molding is smoother than that gas-assisted injection molding.

WATER & GAS ASSISTED INJECTION MOLDED PRODUCTS

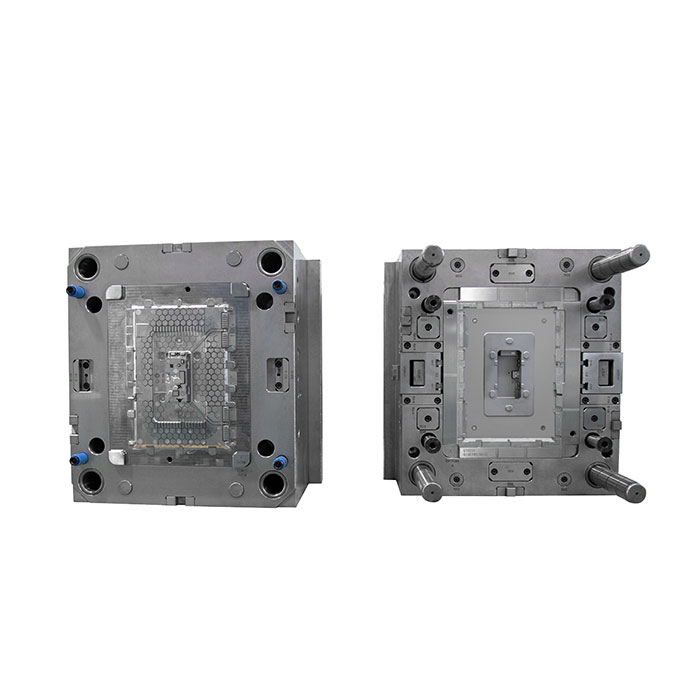

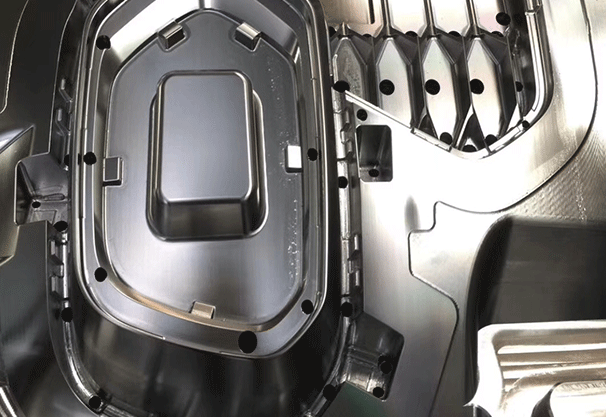

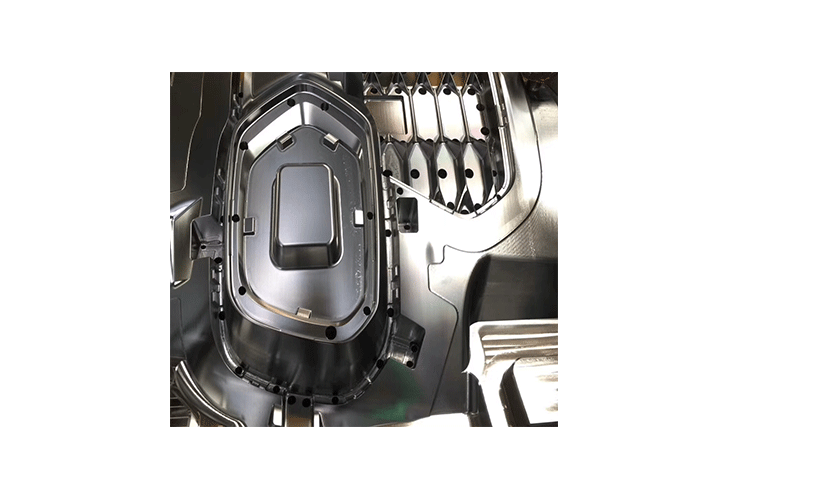

TV Frame Mold

Pushing the liquid plastic into the cavity and core side by high pressure during the injection process, and the gas pressure is maintained to form a hollow section inside the thick wall of the plastic part, the injection process is called gas-assisted injection molding.

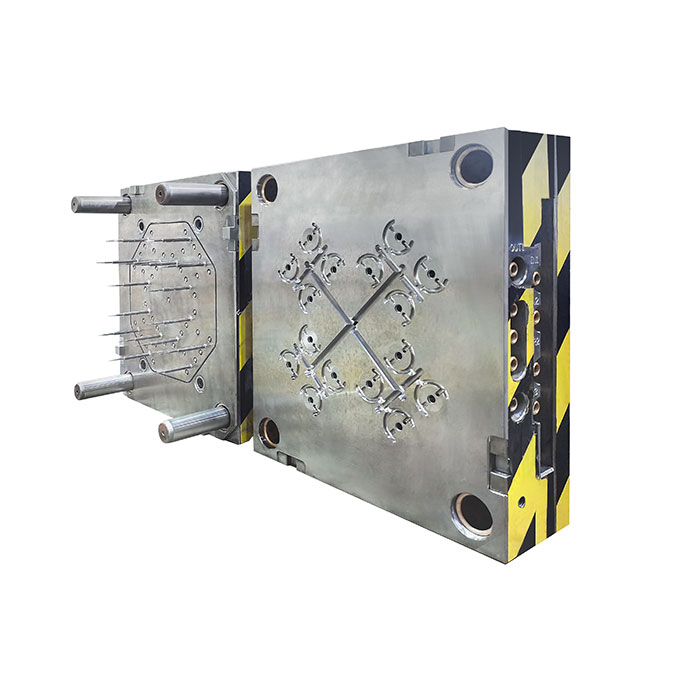

Bike Frame Mold for Kids

During plastic molding processing, gas injection mouldingis abbreviated as GAIM, which is a relatively new molding processing technology, this technology is comprehensively developed on the basis of the design and manufacture of traditional injection molding molds and blow molding molds, and entered the practical stage in the 1990s, gas-assisted injection molding has huge technical application advantages and can produce significant economic benefits.

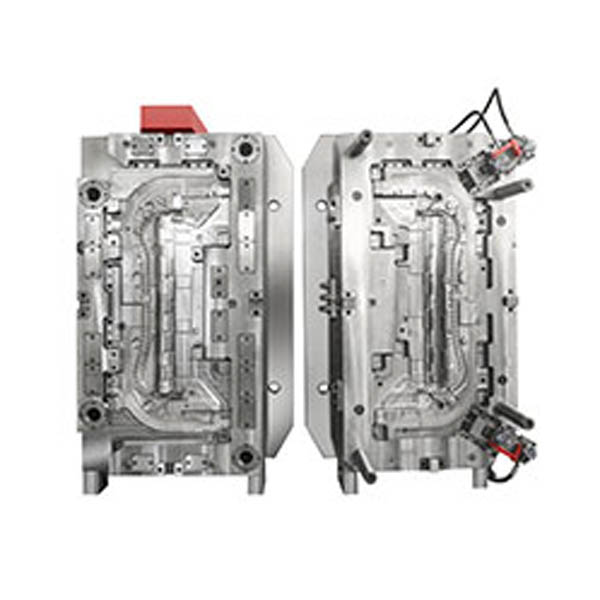

Car Ceiling Handle Injection Mould

When plastic injection molding, the melt is under the injection pressure and enters the mold cavity, on the same section, the flow rate of each gate is different, the fastest in the middle, the closer to the cavity wall, the slower the flow rate, and it contacts the cavity wall, the speed of the first layer is zero.

Water Assisted Injection Mould

Because the flow rate of the outer layer of the melt is slow and the speed of the inner layer is fast, the inner layer of melt will roll outwards and stick to the mold cavity while advancing.

Engine Coolant Pipe

In the gas injection moldprocess, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.

Plastic Pipe Mold

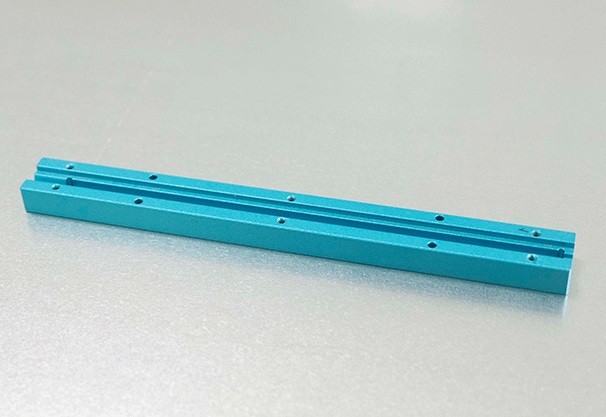

The booster pressurizes the nitrogen in the low-pressure storage cylinder into workable high-pressure nitrogen, and stores it in the high-pressure nitrogen cylinder, the maximum pressure of the nitrogen can reach 35MPa in the process.

Automotive Water Intake Manifold Mould

Gas injection methods can be divided into two types, one is to inject gas together with the melt through the machine nozzle, and the other is to directly inject gas into the runner or cavity through the gas injection element (gas needle), the latter is divided into single-point intake and multi-point intake.

More

Gas Assisted & Water Assisted Injection Molding Differences

Gas-Assisted Injection Molding Process

Gas-assisted injection molding is roughly divided into 4 stages: plastic injection, gas injection, pressure-holding cooling, and gas discharge.

Gas-assisted injection moldclassification

- custom injection moulding: under-material injection molding is also called short shot, inject part of the plastic melt (usually 50%-90% of the cavity volume) into the mold cavity first, and then inject gas to use push the melt to complete mold filling and pressure holding by gas, the gas injection time and gas pressure are very important to the product quality, to inject the gas too early or pressure is too high will cause the gas to penetrate the melt front, otherwise it will lead to incomplete feeding and surface defects. In this type of gas injection moulding process, when the gas pressure is too high and the gas is injected too early, gas penetration cannot be avoided, if the gas pressure is too low and the gas is injected too late, the gas will not enter the plastic and will not be able to promote the flow of the melt front. Increasing the initial air pressure can avoid stagnation of the forward melt, and there will be no traces on the surface of the product, the under-material injection process is suitable for the molding of rod-shaped products or plate-shaped products with partial walls thickness.

As one of gas injection moulding manufacturers, we will provide more kinds of high quality products for sale, anything you need, please contact us.

Send product request

Other supplier products

| Multi Cavity Mold | Multi Cavity Mold Design The runner filling balance must be considered when designing the multi-cavity mold in order to ensure the best effect o... | |

| Medical Pipette Tip Mold | Medical Pipette Tips USM as a medical plastic mouldingsupplier provides products including medical device plastic parts, suction tips, blood colle... | |

| Voice Operated Switch Mold | Switch Plate Mold The function of the smart home system is extensible, so it can meet the demands of different users. For example, the user's smar... | |

| Pre-Deformation Mold | Pre Deformation Mold When the plastic material rushes into the mold cavity, it loses heat due to heat conduction, and the melted plastic will free... | |

| Cold Runner & Hot Runner Plastic Mold | Generally, the temperature-sensitive wire is composed of steel wire insulated with a heat-sensitive material, the temperature sensing wire is commo... |

Same products

| Mold Components | Seller: Packson Mold Co.,Ltd | We provide custom made plastic parts-Sliders, inserts, lifters, blocks, ejector pins, and other m... | |

| Custom Metal Machining Parts | Seller: Packson Mold Co.,Ltd | Packson provides our customers a various CNC machining services to our customers, including milli... | |

| Clean Room Injection | Seller: Packson Mold Co.,Ltd | Packson - Medial Injection Moulding Cleanroom Expert Packson specializes in delivering top-notch ... | |

| Medical Plastic Injection Molding | Seller: Packson Mold Co.,Ltd | Packson - Medical Plastic Injection Molding Expert Packson sets itself apart from other medical i... | |

| CNC Metal Machining Parts | Seller: Packson Mold Co.,Ltd | Packson is a contract manufacturer specializing in CNC Milling, CNC Turning, CNC Drilling service... |