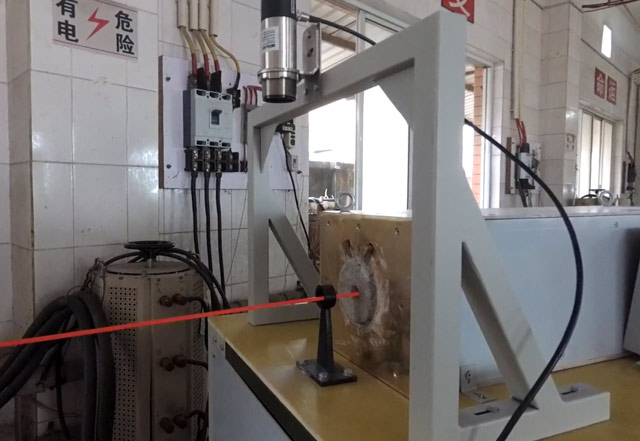

Medium Frequency Induction Heating Machine

If you need hot forging for large workpieces, smelting for ferrous or non-ferrous metals or deep heat treatment, the MFS series of intermediate frequency induction heating equipment is your most correct choice.

Advantages of medium frequency induction heating equipment

The induction heating speed is fast and the temperature uniform is good. The MFS series induction heating power supplycan design the operating frequency according to the actual needs of customers. The workpiece is non-contact heating. The metal workpiece heats itself through the alternating eddy current, which has high efficiency and a good temperature uniform effect.

The induction heating energy efficiency is high. As a mature medium frequency induction heating series, the MFS series adopts IGBT and adjusts the power by adjusting the wave, and uses high-quality copper material as the main circuit base layer, which can effectively reduce the loss of the components and the circuit itself.

The design of this medium frequency induction heating machine can also allow customers to directly set the working status (power, working mode, etc.) of the heating equipment through the touch screen. At the same time, customers can also accept external PLC control through RS485 or reserved external signal I/O modules.

Standard MFS can be applied to wide voltage fluctuation (*360V~440V), and non-standard voltage power supply can also be customized according to the actual situation of customers.

This medium frequency induction furnace is also equipped with a condition monitoring system(CMS) and a built-in condition detection system just like any other induction heating system launched by JKZ. Through the single-chip microcomputer, this medium frequencty induction heating series can effectively monitor the temperature, current, voltage, water flow, etc. of the main components of the equipment. Problems like overvoltage, undervoltage, overtemperature, water shortage, phase failure, and overcurrent can be easily detected.

With different output modules, MFS series induction heating power supplies can complete induction forging, induction quenching, and non-ferrous metal induction smelting.

JKZ, as an excellent induction heating machine manufacturer, offers a wide range of china heating machinefor you to choose from.

Send product request

Other supplier products

| Induction Annealing And Normalizing | Induction annealingand induction tempering are very important processes in the heat treatment of the metal workpiece. These two processes can effec... | |

| Portable Induction Welding Machine | Portable Induction Welding Machine JKZ Induction Heating is mainly engaged in producing full solid state induction welding equipmentwith high, s... | |

| Induction Heating Machines In Wire And Cable | A lot of cables need to be heat-treated before further processing. There is a lot of request about the online induction heating wire with fast spee... | |

| Induction Shrink Fitting | JKZ,induction heating power supply,can provide you a complete induction heating equipment experience service. Our service staff will give customers... | |

| Medium Frequency Induction Heating Machine | JKZ,induction heating power supply,can provide you a complete induction heating equipment experience service. Our service staff will give customers... |

Same products

| Electric water tank | Seller: INLIGHT NEW ENERGY | Electric Water Heater Tanks are reliable, efficient storage solutions designed to provide a const... | |

| Top Heat Recovery Gas Heating Unit | Seller: Fujian Air Technology Systems Co., Ltd | Applications: solving the heating needs for high and large space(H:4-30m). Adopting direct combus... | |

| AIFEN F5 Pro 1000W Hot Air Gun for Electronics Maintenance | Seller: Phonefix | AIFEN F5 PRO High Power Hot Air Rework Station delivers 1000W performance for mobile phone repair... | |

| YCS R1 Ultra Hot Air Rework Station for BGA and CPU Repair | Seller: Phonefix | The YCS R1 Ultra and YCS R1 Ultra Limited Edition 1450W High Power Hot Air Gun Rework Station exc... | |

| MECHANIC 958HT Small Digital Hot Air Gun For IC Disassembly | Seller: ShenZhen VIP FIXPHONE Technology Co., Ltd, | Description Mechanic 958HT 600W Portable Handheld Hot Air Gun with HD Digital Display and Button ... |