Steel pipe facing machine

Groove machine is a pipe or plate in front of the welding end chamfering groove of special tools, solved the flame cutting, polishing machine, grinding and other non-standard operation process Angle, slope surface is rough, noisy work such as faults, with the features of easy operation, standard, smooth surface, etc.

From processing materials characteristics are divided into: the pipe facing machine and tablet two broad categories of beveling machine, pipe facing machine from the drive power can be divided into: electric pipe facing machine, pneumatic pipe facing machine; From the fixed way points: increase within pipe groove machine, card outside the pipe facing machine; Plate groove machine is divided into portable tablet groove machine, automatic walking tablet groove machine, stationary flat groove machine. Multi-function groove machine, also called portable multi-function tube plate groove machine, is a kind of steel plate groove machine, used for welding sheet metal before burring and groove processing, this machine is mainly by using the theory of rolling washing, wash the cut edge of the steel plate according to the Angle, in order to get the welding groove. Apply to steel, cast iron, hard plastic, non-ferrous metal materials such as! Groove machine is a pipe or plate in front of the welding end chamfering groove of special tools, solved the flame cutting, polishing machine, grinding and other non-standard operation process Angle, slope surface is rough, noisy work such as faults, with the features of easy operation, standard, smooth surface, etc. Groove machine has a variety of specifications, for power, oil, chemical industry, shipbuilding, steel structure, such as professional installation and maintenance, etc provided an advanced tool, the tool can greatly improve the work efficiency, reduce the cost.

Is mainly convenient heat cutting: according to the customer, at the same time, groove customer quality requirement is not high, after high temperature treatment groove material can produce a physical change, demanding the user generally don't recommend option. Physical cutting: according to the groove quality requirements higher customer, groove quantity bigger clients at the same time, groove cutting does not change the material belongs to the physical.

Other supplier products

|

|

Intermediate frequency hydraulic expanding machine |

Cangzhou tengda machinery factory is the most professional hydraulic equipment manufacturers in north China, specializing in the production and man... |

|

|

Steel pipe facing machine |

Groove machine is a pipe or plate in front of the welding end chamfering groove of special tools, solved the flame cutting, polishing machine, grin... |

|

|

Steel pipe hydrostatic testing machine |

Hydrostatic testing machine instructions:

1, the preparation before the operation

1) check whether water tank water to fill

(2) check vertica... |

|

|

Steel pipe cold drawing machine |

Cold drawn steel machine is special equipment of cold drawn steel bar. Its a lot of more phyletic, according to the different ways have different t... |

|

|

Cold heat pipe bender |

Cold heat pipe bender it can put the steel pipe, square tube, round tube, copper pipe, aluminum pipe,

Without having to manufacture elbow: save m... |

All supplier products

Same products

|

|

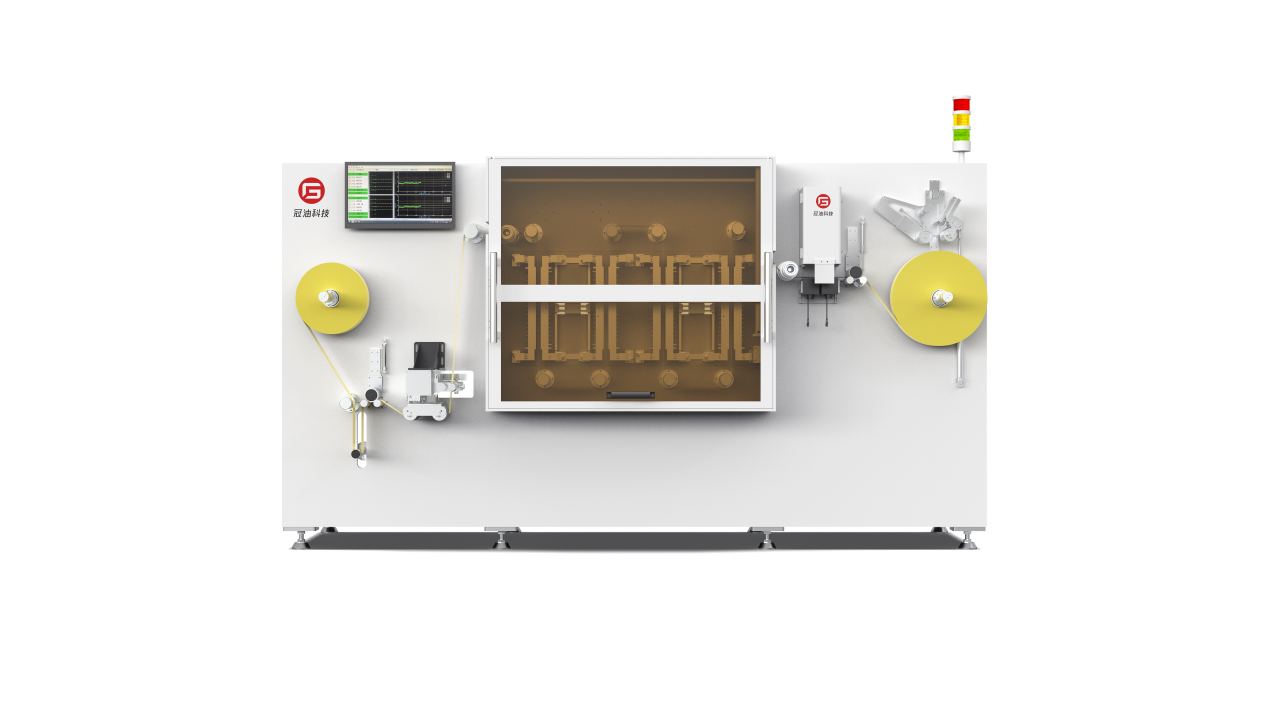

The Single Workstation Electrostatic Perforating Machine |

Seller: Wuhan Guan You Technology Co., Ltd. |

The single workstation electrostatic perforating machineis a professional cigarette paper static ... |

|

|

YZH WHEN1510 Stationary Pedestal Rockbreaker Boom |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its... |

|

|

YZH WHEN1410 Stationary Pedestal Rockbreaker |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr... |

|

|

JY-160S2 Standard Plastic Injection Machine |

Seller: Dongguan Jieyang Machinery Co., Ltd |

Straight screw ejected assembly.

Two(three)-phase temperature, ejected speed, backing pressure a... |

|

|

WPC Terrace panel extrusion line |

Seller: Qingdao Trusty Plastic Machinery Co.,Ltd |

Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... |