Vacuum Casting Services

What is the Vacuum Casting?

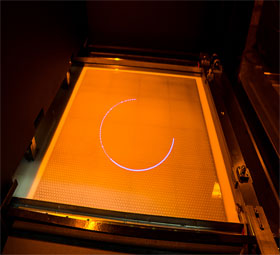

The vacuum casting technology which uses prototype (SLA laser rapid prototyping piece, CNC products) to make silicone mold under vacuum, and is poured under vacuum conditions, such as PU, ABS, etc. Vacuum casting is also used to clone the prototype or copy the piece. It has different types including , vacuum pressure casting, vacuum sand casting and so on. This method is especially suitable for small batch production. It is a low-cost solution to solve experimental production and small batch production in a short time, and can also meet the functional test proofing of some structurally complicated engineering samples.

Advantages of Vacuum Casting

The cost is low and the production cycle of the product is relatively short. Less waste and processing costs are much lower than CNC machining and 3D printing.

It is suitable for the processing and production of small batch products. After making an original version, it can be copied according to the original version, and the production efficiency is high.

Good mold operation. The soft molds after curing are all transparent or translucent, have good tensile strength, and are easy to cut and shape.

The probability of processing failure is small. As long as there is no problem with the original, the copy will naturally not go wrong.

Good repeatability. The silicone for molding has good fluidity before curing, and the fine structure and decoration of the model can be accurately maintained with vacuum defoaming.

We have the world's most advanced , and provide post-processing lines such as polishing, painting and assembly. We can provide small batch production of small and medium-sized parts quikly. If you are looking for reliable vacuum casting service, please contact our professional team at or contact us by visiting our website, we will provide quotes and suggestions free of charge.

Send product request

Other supplier products

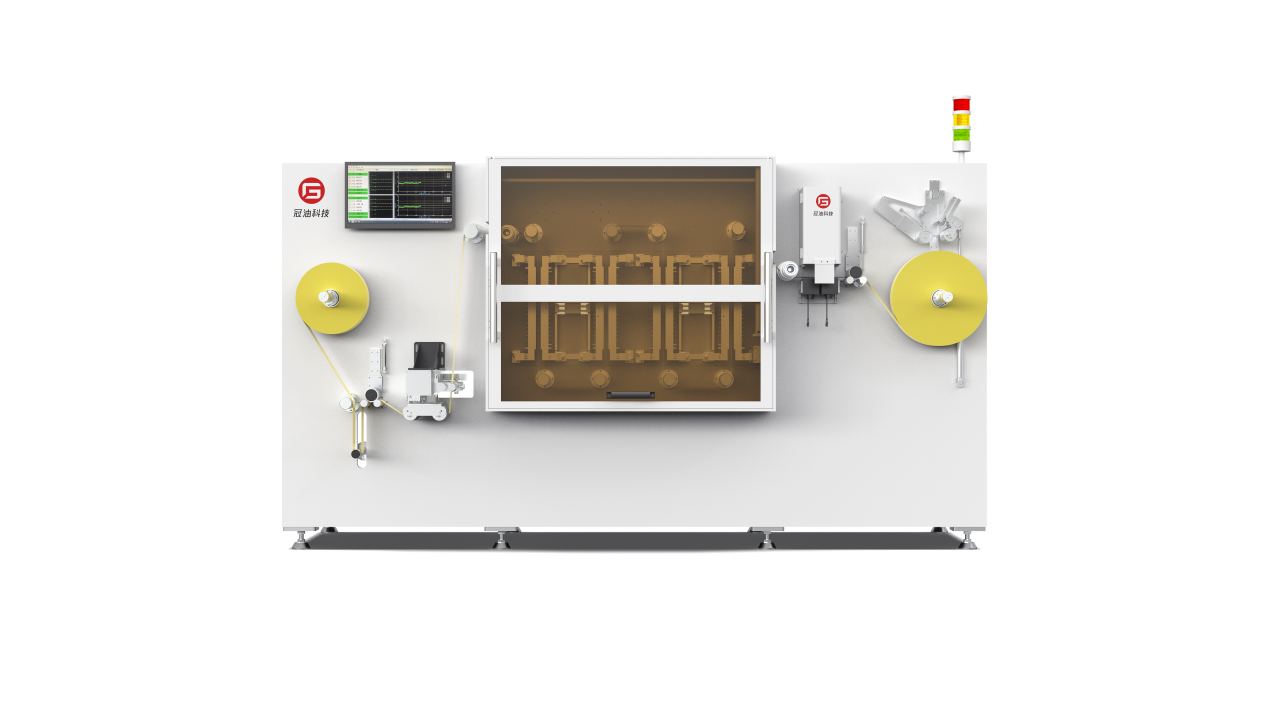

| PFM800 Automated Vacuum Casting System | It adopts Germany imported Rietschle vacuum pump, ultimate vacuum to ensure complete defoaming; the inner tank selects 5mm thick stainless steel pl... | |

| What is a Mold? | What is a Mold? In industrial production, various types of presses and special tools mounted on the press are used to produce metal or non-metal ma... | |

| ProtoFab SLA100 DLC | Compact & Economical Our most affordable SLA 3D printers with build sizes of 100 mm X 100 mm X 50 mm respectively. These compact sizes are idea... | |

| PFM1500 Automated vacuum casting system | It adopts Germany imported Rietschle vacuum pump, ultimate vacuum to ensure complete defoaming; the inner tank selects 5mm thick stainless steel pl... | |

| 3D Printing Services | What is 3D Printing Service? 3D printing technology is a collective term for a series of rapid prototyping technologies, the basic principle of whi... |

Same products

| The Single Workstation Electrostatic Perforating Machine | Seller: Wuhan Guan You Technology Co., Ltd. | The single workstation electrostatic perforating machineis a professional cigarette paper static ... | |

| YZH WHEN1510 Stationary Pedestal Rockbreaker Boom | Seller: Shandong Yirun Foundation Engineering Co., Ltd | Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its... | |

| YZH WHEN1410 Stationary Pedestal Rockbreaker | Seller: Shandong Yirun Foundation Engineering Co., Ltd | YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr... | |

| JY-160S2 Standard Plastic Injection Machine | Seller: Dongguan Jieyang Machinery Co., Ltd | Straight screw ejected assembly. Two(three)-phase temperature, ejected speed, backing pressure a... | |

| WPC Terrace panel extrusion line | Seller: Qingdao Trusty Plastic Machinery Co.,Ltd | Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... |