Vacuum Casting Services

What is the Vacuum Casting?

The vacuum casting technology which uses prototype (SLA laser rapid prototyping piece, CNC products) to make silicone mold under vacuum, and is poured under vacuum conditions, such as PU, ABS, etc. Vacuum casting is also used to clone the prototype or copy the piece. It has different types including , vacuum pressure casting, vacuum sand casting and so on. This method is especially suitable for small batch production. It is a low-cost solution to solve experimental production and small batch production in a short time, and can also meet the functional test proofing of some structurally complicated engineering samples.

Advantages of Vacuum Casting

The cost is low and the production cycle of the product is relatively short. Less waste and processing costs are much lower than CNC machining and 3D printing.

It is suitable for the processing and production of small batch products. After making an original version, it can be copied according to the original version, and the production efficiency is high.

Good mold operation. The soft molds after curing are all transparent or translucent, have good tensile strength, and are easy to cut and shape.

The probability of processing failure is small. As long as there is no problem with the original, the copy will naturally not go wrong.

Good repeatability. The silicone for molding has good fluidity before curing, and the fine structure and decoration of the model can be accurately maintained with vacuum defoaming.

We have the world's most advanced , and provide post-processing lines such as polishing, painting and assembly. We can provide small batch production of small and medium-sized parts quikly. If you are looking for reliable vacuum casting service, please contact our professional team at or contact us by visiting our website, we will provide quotes and suggestions free of charge.

在线联系供应商

Other supplier products

| What is a Mold? | What is a Mold? In industrial production, various types of presses and special tools mounted on the press are used to produce metal or non-metal ma... | |

| Yacht Model Making Case Study | Project name:Yacht model Material: ABS engineering plastics Process: CNC machining Post treatment: Painting, plating Qty: 1 set Advantages: high pr... | |

| Sheet metal processing or sheet metal fabrication includes: folding, shearing, punching, welding, riveting, splicing and other processes. In general, the process of forming a sheet by hand or mechanic | The china vacuum castingtechnology which uses prototype (SLA laser rapid prototyping piece, CNC products) to make silicone mold under vacuum, and i... | |

| Low-Volume Manufacturing Service | What is Low-volume Manufacturing? Small batch trial production is a transitional link from small trials to pilot tests to industrial production. Pr... | |

| ProtoFab PF-M 150 | WIDE CHOICE OF MATERIALS This entry level SLM printer uses a broad choice of materials including stainless steel, Cobalt Chrome, Bronze, Titanium, ... |

Same products

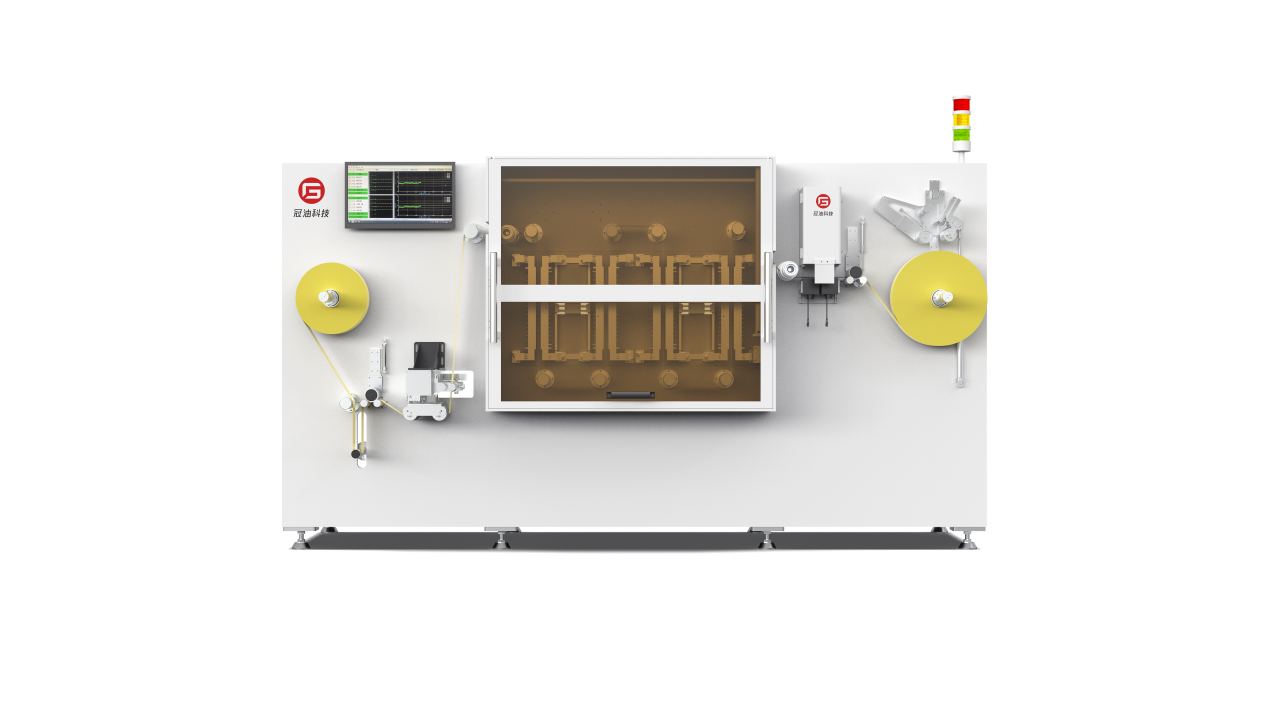

| 单工位静电打孔机 | 卖方: 武汉冠油科技有限公司 | 单工位静电打孔机是一款专业应用于国内外香烟接装纸生产厂家和卷烟生产行业的接装纸静电打孔机,具有独立知识产权。相比激光打孔机,静电打孔在实现高透气度的同时,能保持稳定性,避免激光打孔时孔径过大导致... | |

| YZH WHEN1500固定式液压机械臂 | 卖方: 山东伊润基础工程有限公司 | 以下是YZH WHEN1500固定式液压拆除臂的详细介绍,包括其特点、优点和案例研究:YZH WHEN1510固定式底座碎石机臂的特点:智能多模式控制:支持驾驶室操作、无线/有线远程控制、光纤+... | |

| YZH WHEN1410固定式底座碎石机 | 卖方: 山东伊润基础工程有限公司 | YZH WHEN1410固定式底座碎石机是一种专为采矿、冶金及相关行业大型物料的二次破碎而设计的专用设备。通过更换附件(如液压锤或莲花爪),它可以执行多种功能,包括破碎、抓取和拆除。 WHEN... | |

| JY-160S2 Standard Plastic Injection Machine | 卖方: Dongguan Jieyang Machinery Co., Ltd | Straight screw ejected assembly. Two(three)-phase temperature, ejected speed, backing pressure a... | |

| WPC 木塑室外地板挤出生产线 | 卖方: Qingdao Trusty Plastic Machinery Co.,Ltd | 木塑复合材料(WPC)与木材不同,具有更高的耐腐蚀性和耐温性。其低残余湿度和多孔结构也赋予了它更高的强度。凭借这一特性,WPC地板(或甲板)被广泛应用于各种休闲场所的建造,如夏季咖啡馆、凉亭和门... |