Dry magnetic separator

Introduction

Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force. Dry magnetic separator is used to separate the ores, used for preselecting the low grade ores. High concentration ratio and grade of ores into the mill can be greatly improved. It is used for purifying the iron ore concentrate and removing locked particle and gangue.

Features

This Dry Magnetic Separator is suitable for processing various bulk materials and will not blocked for its compact structure

Also has disaggregating function for sticky and poor-fluidity powders

Stainless steel machine and full-closed operation enable an easy clean

This high gradient magnetic separator has optimized magnetic circuit, which offers high intensity magnetic field for better separating effect

Dry Magnetic Separator working under high temperature

Application

Used for low grade ore pre-separation. The concentration ratio of this equipment is high and the machine can improve the grinding grade by a large margin

Used for purifying iron ore concentrate and removing locked particle and gangue

Used for reselecting the gangue

Used for removing the magnetic impurity from powdery material

Working principle

When materials go through the permanent magnetic drum, the magnetic particles are absorbed to the drum surface and discharged through the magnetic product area. Meanwhile, the non-magnetic particles are ejected from the drum surface under the influence of the centrifugal force and gravitation and discharged through the non-magnetic product area.

Technical parameters

Model Drum diameter

x length(mm) Rotating

speed

(r.p.m) Magnetic induction

of the drum surface

in ore separating

area(mt) Upper limit of

particle size of

handled ores

(mm) Capacity (t/h) Wight of

magnetic

drum(kg) Motor power(kw) Weight (kg)

CTG-0609 600×900 50-150 >120 7-0 5-10 800 7.5 1800

CTG-0612 600×1200 10-15 1000 2000

CTG-0612 800×1200 70-150 140 20-25 1400 2500

CTG-0818 800×1800 50-150 >120 15-20 1800 11 3000

CTG-0618 600×1800 70-150 140 40-45 2100 3600

CTG-0615 800×1500 30-45 2500 4200

Order online

Send product request

Other supplier products

| Circular vibrating screen | Circular vibrating screen is a kind of effective vibrating screen with multi-layers. It employs cylindrical eccentric shaft vibration exciter and p... | |

| Autogenous ,Semi-autogenous mill | Introduction This equipment is modified by our experts and with the features of greatly energy saving, no powder pollution, less floor area and la... | |

| Automatic flocculant preparation system | Introduction Automatic flocculant preparation system is designed for preparation of solution of powdered flocculant. The unit together with the fl... | |

| Efficient improved thickener | Thickeners are used for dewatering slurries of either tailings or product. A thickener is a large circular tank that is used to settle out the soli... | |

| Xinhai abrasion resistant rubber | Introduction The rubber----which is manufactured with the wet production technology in the state of liquid phrase----is not subject to damages cau... |

Same products

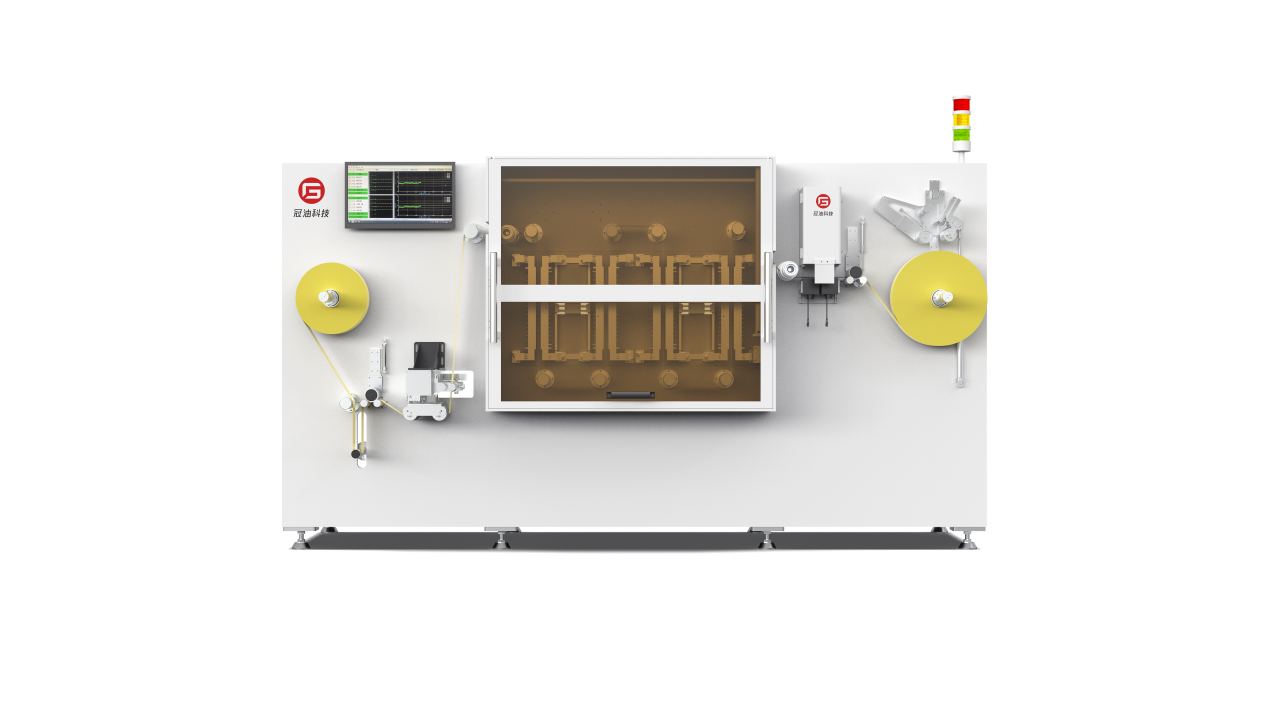

| The Single Workstation Electrostatic Perforating Machine | Seller: Wuhan Guan You Technology Co., Ltd. | The single workstation electrostatic perforating machineis a professional cigarette paper static ... | |

| YZH WHEN1510 Stationary Pedestal Rockbreaker Boom | Seller: Shandong Yirun Foundation Engineering Co., Ltd | Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its... | |

| YZH WHEN1410 Stationary Pedestal Rockbreaker | Seller: Shandong Yirun Foundation Engineering Co., Ltd | YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr... | |

| JY-160S2 Standard Plastic Injection Machine | Seller: Dongguan Jieyang Machinery Co., Ltd | Straight screw ejected assembly. Two(three)-phase temperature, ejected speed, backing pressure a... | |

| WPC Terrace panel extrusion line | Seller: Qingdao Trusty Plastic Machinery Co.,Ltd | Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... |