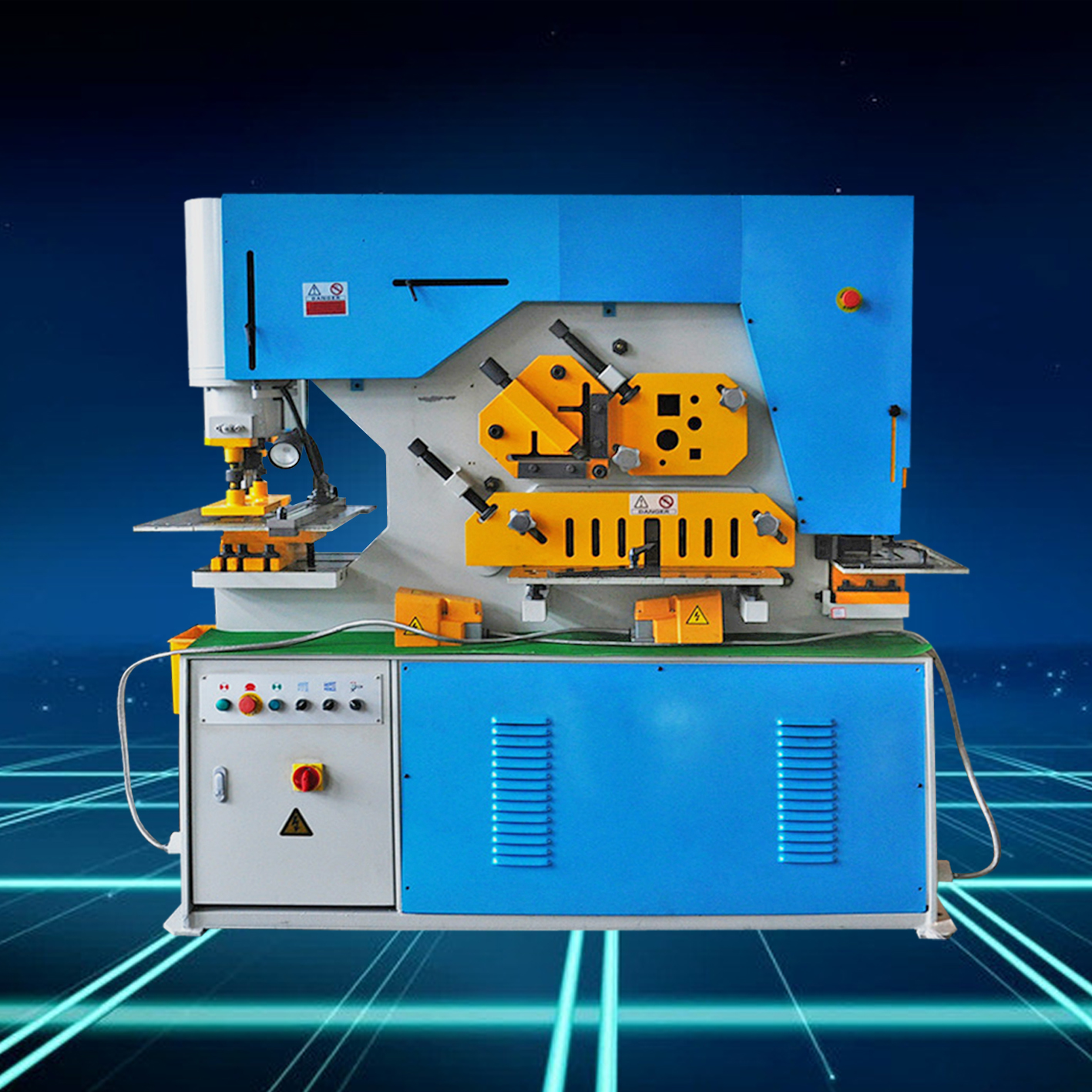

APEC Hydraulic Ironworker AIW-90

APEC BrandAIW seriesIronworker features multiple functions, including: punching all kinds of holes (round hole, square hole, oblong hole), louver punching, steel plate punching, flat bar punching, angle steel punching, C-channel punching, H-beam punching, I-beam punching, profile steel shearing (channel shearing, I-beam shearing, round/square bar shearing, flat bar shearing, T-bar shearing, steel plate shearing, angle steel shearing), notching, press brake, angle steel notching , bending, pipe notching. It comes standard with: quick-change coupling nut & sleeve, squaring arm with scale, electronic back gauge, gauging table with stops, punching base table, safety guards and more.We can design any special tools according to your metal fabricating requirements.

APEC Brand AIW-S seriesis improved machine on the base of standard AIW series. It goes along with automatic holding system and temperature cooling system.

Automatic Holding System: There is automatic holding system in angle steel shearing and plate shearing work position. The holders will fix the position of work-piece, in this way, the accuracy is better and more safety for workers meanwhile save time and Improve working efficiency.Temperature cooling system:Once start the machine,the cooling system starts working automatically.The hydraulic oil temperature always stays at 60 degree or less.It is applicable and safety for processing in quantities and long time.

Features

- b. Valve: Yuken, Japanc. Pump: Atos, Italyd. Oil Seals: NOK, Japane. Timer Relay: OMRON, Japanf. Wiring Terminal Block:WEIDMULLER, Germanyg. Motor: Weiteli, China

AIW SERIES Hydraulic Ironworker WithVery good price/performance ratio

VariousAIW SERIES Hydraulic Ironworker capacity from 45T to 400Tto meet your requirement.

AIW Series Hydraulic Ironworkeruse hydraulic transmission. Light weight, low noise, reliable performance.

The operation of hydraulic ironworker is controlled by foot switch.

Technical Parameters:

|

Technical Parameter |

||||

|

Item |

Unit |

Value |

||

|

1 |

Hole Punching |

Punching Pressure |

KN |

900 |

|

mm |

20 |

|||

|

mm |

30 |

|||

|

Depth of Throat |

mm |

355 |

||

|

mm |

80 |

|||

|

Stroke Times |

times/min |

8-22 |

||

|

2 |

Flat-bar Shearing |

Angle of Shear |

degree |

8° |

|

mm |

20 |

|||

|

Flat Bar (W×T) |

mm |

480x10 |

||

|

330x20 |

||||

|

3 |

Angle Steel Shearing |

90° Shearing of Equal Angle Steel |

mm |

140x140x12 |

|

45° Shearing of Equal Angle Steel |

mm |

70x70x10 |

||

|

4 |

Profile Steel Shearing |

Round-bar |

mm |

50 |

|

Square-bar |

mm |

45x45 |

||

|

T-bar |

mm |

140x70x12 |

||

|

I-beam |

mm |

160x86x6 |

||

|

C-channel |

mm |

|||

|

5 |

Notching |

Thickness |

mm |

13 |

|

Width |

mm |

57 |

||

|

Depth |

mm |

100 |

||

|

6 |

Material Tensile Strength |

N/mm2 |

450 |

|

|

7 |

Motor Power |

KW |

||

|

8 |

Overall Dimensions(L×W×H) |

mm |

1950x900x1930 |

|

|

9 |

Gross Weight |

Kg |

2600 |

|

Note:Design and specifications subject to change without notice.

Accessories:

The above punching and moulds will be installed in the machine.

For other dies and blades, customers need to order

Installation & Operation Training

APECwill provide you 1-7 day installation and operating training in our factory.

Training After-sales service

- All labels on machines and lay-out drawings, Electrical diagram, Operation Manual, will be in English. The seller should send all necessary files to the buyer since the third week since project execution. All documents in hard copies should be also shipped with machines together.

- a. After all machines are delivered to customer’s factory; Buyer is responsible for all preparation work, e.g. electricity supply, water supply, labors and cranes, etc.b. The buyer will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer’s factory.c. The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD80 per day for each engineer.d. Engineer will give free training lessons to labors in buyer’s factory.

- a.Quantity/Quality Discrepancy to destination port during transportation:In case of quality/quantity discrepancy to destination port in transportation, the buyer should file claim within 30 days after the arrival of the goods at port of destination. The seller will not be responsible for any discrepancy of the goods caused by shipping company and other transportation organization and/or post office.b.Guarantee period and after-sales services: 13 months since date of bill of ladingDuring this guarantee period, the seller will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, the seller will provide the buyer spare parts at cost price.c.Long-term service:The seller will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

FAQS:

T/T, L/C at sightare acceptable by us.

It is up to your requirement. EX-WORS, FOB, CIF, CFR and so on are acceptableby us.

25 working days from our accountant confirm your deposit payment.

We will arrange the machine production from our accountant confirm your deposit payment. The deposit is 30% of the contract.The balance should be paid up before loading machines.

13 months quality guaranty for the main spare parts, not include quick-wears parts,like blade, punch, die and so on.If theparts of machines have problems, whichare caused by its own quality, we will provide theaccessories for free.

Send product request

Other supplier products

| APEC Hydraulic Ironworker AIW-90 | APEC BrandAIW seriesIronworker features multiple functions, including: punching all kinds of holes (round hole, square hole, oblong hole), louver p... | |

| Jiangsu APEC Lathe Manufacturing Co.,Ltd | APEC Lathe is a professional manufacturer specialized in the design, production and sales of all types of metal processing machine, including mecha... | |

| APEC Hydraulic Ironworker AIW-120 | APEC Brand AIW series Ironworker features multiple functions, including: punching all kinds of holes (round hole, square hole, oblong hole), louver... | |

| APEC Hydraulic Ironworker AIW-60 | APEC BrandAIW seriesIronworker features multiple functions, including: punching all kinds of holes (round hole, square hole, oblong hole), louver p... |