Coaxial Wire Stripping Machine

Coaxial Wire Stripping Machine

-

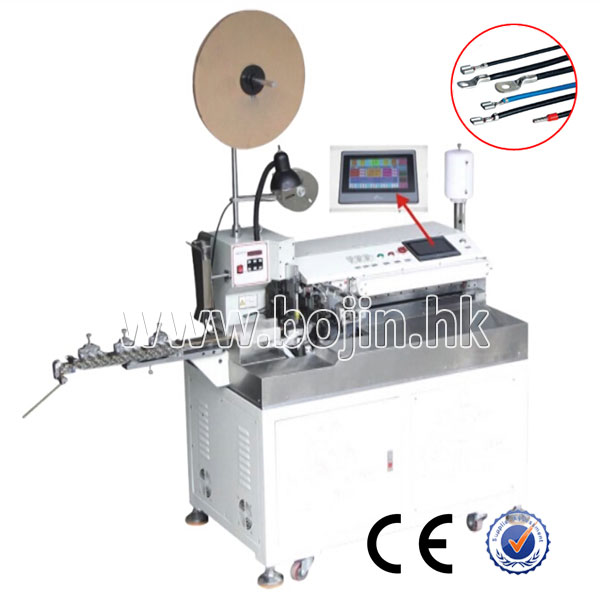

BJ-06TZ Automatic Coaxial Cable Cutting And Stripping Machine

* Cable Type: coaxial-cable

* Memory: 40

* LCD Display size: 153mm*85mm English & Chinese Panel

* Max. Cable Dimater: up to 4mm & 5.5mm (0.64-4.0mm) (1.0-5.5mm)

* Cutting depth of the unit: 0.01mm -

BJ-03TZ Coaxial Cable Stripping Machine

* Max. Cable Dimater: up to 15mm

* Cutting depth of the unit: 0.01mm

* Max. peeling length: 150mm

* Blade: 4 pieces Material:imported tungsten steel(Switzerland)

* Centering slab: 4 pieces Material:imported tungsten steel

* Productivity: 400-500pcs/h(depend on the cable length and type) -

BJ-04TZ Coaxial Wire Stripping Machine

* Max. Cable Dimater:0.2-up to 6.99mm

* Cutting depth of the unit:0.01mm

* Max. peeling length:48mm

* Drive mode:Motor/ Ball screw drive(Japan)

* Centering slab:2 pieces Material:imported tungsten steel

* Opening way:Manual operation/Pedal

- «

- 1

- »

Operating procedures of semi-automatic coaxial wire stripping machine.

1. Purpose

Establish proper equipment to prevent accidents and ensure the normal operation of equipment and improve work efficiency.

2. Precautions before work

2.1 The status symbol of each equipment shall be marked with the equipment name, equipment number, the initial opening time of the equipment and the department that uses the equipment.

2.2 Check whether the power is connected before work.

2.3 Check whether the working area is clean and in place. If the work site is to be cleaned, power must be turned off to avoid accidents.

2.4 Check whether the connection part of the machine is loose. If found, contact the equipment technician for inspection without delay.

2.5 Staff must be trained before the operation, and they can be hired after training.

3. Matters with attention during work.

3.1 When the machine is turned on, if there is any abnormal sound, please inform the equipment technician for inspection in time.

3.2 The staff shall not be allowed to move, disassemble equipment, test instruments, adjust the parameters set by the equipment. Contact the equipment technician if it is necessary.

3.3 The line should be placed in the middle of the clamps to avoid clamping the line.

3.4 If there is a new type of wire, it needs to be rotated. Firstly, the equipment technician shall adjust the equipment parameters and adjust the optimal state to be operated by the staff.

3.5 If abnormal conditions or abnormal detection results are found in the using process, the application shall be terminated immediately. The equipment technician shall be adjusted, and the calibration can be put into use after the repair.

3.6 Confirmation of deviation of inspection equipment shall be conducted to re-evaluate the products in the past and re-test if necessary.

Send product request

Other supplier products

| Automatic Bobbin Machine | Functions of bobbin machine and common debugging methods: Being familiar with equipment function and winding process When buying the bobbin machi... | |

| Fully Automatic Terminal Crimping Machine | The operation procedure of Full Automatic Crimping Machine 1. The operator must be trained to post the certificate for working;2. Pre-operation re... | |

| Enameled Wire Stripping Machine | Installation and use of . Choose appropriate peeling wheel and install them on the machine. Put two enameled wire in the middle of the peeling whe... | |

| ZCUT-2 Vinyl Tape Dispenser | Specifications ofZCUT-2 Vinyl Tape Dispenser Available Tape Width: 3 ~ 25mm Available Cut Length: 13 ~ 60mm Adjusting Method: Screw Bobbin:... | |

| BJ-210 Automatic Labeling Machine | Operation Video ofBJ-210 Automatic Labeling Machine Feature ofBJ-210 Automatic Labeling Machine Bottle labelers enable the user to label al... |

Same products

| Rail Welder A Frame aligners railway welding tools | Seller: 834406 | 产品描述 A型车架 A-Frame 是一种导轨对准器,可精确对准要焊接的导轨。该设备在焊接操作期间将导轨固定到位。 | |

| 2 parts fluid mixing dispenser 2 component dosing epoxy PU silicon rubber vacuum system | Seller: 824681 | What is the difference between 2K AB adhesive materials manual potting machine and robot pottingm... | |

| Horizontal Machining Center | Seller: Xilong (Shanghai) Machine Tool Co., Ltd. | Horizontal Machining Center parts can automatically finish four sides milling, boring, drilling, ... | |

| Horizontal Lathe | Seller: Xilong (Shanghai) Machine Tool Co., Ltd. | As a professional horizontal lathe manufacturerand horizontal lathe factory, Sealion Machine Tool... | |

| Gantry Machining Center | Seller: Xilong (Shanghai) Machine Tool Co., Ltd. | SEALION supplies Gantry Machining Center both tables moving type or gantry moving type. Gantry ty... |