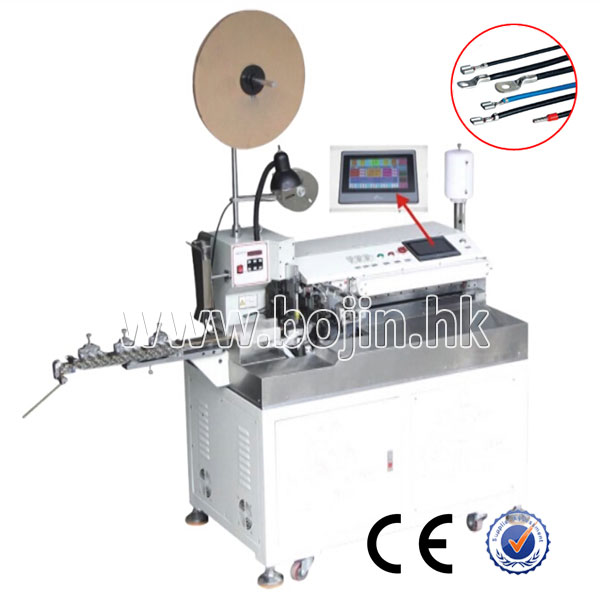

Automatic Wire Feeder

Safety precautions of thewire feedercontroller:

1. Ask professional technicians to install, connect and debug the device. In the conditions of electrification, the device line cannot be mounted, removed or replaced.

2. It is necessary to install the protector between the power input and current source( battery) of this product, in case of causing any dangerous incidents and deadly injure. Things need to be added: over current protector, insurance, and the emergency switch. Please do a good job of isolation and insulation between the earth and the equipment.

3. If indeed need to debug this product with charge, please choose a non-metal screwdriver with a good insulation or a special debugging tool.

4. This product should be installed in the environment with good atmospheric conditions.

5. This product can not be applied directly in the improper environment such as high humidity, dust, corrosive gas, and strong vibration.

6. Do not connect the wire with electrification.

7. Please select an insulated conductor and a shield line which is matched with voltage and current of the driver, and connect them.

8. There is no reverse defensive function of power supply inside the driver. Please ensure that the power supply must be the input of the driver and the external power supply with the positive pole and the negative pole, otherwise, the driver will be damaged.

9. Please use the suitable tool to connect and ensure it to be right.

Warnings:

1. No matter what happens, the signal wire and logical controlling line cannot be bound and mixed with power input wire, the output line ( motor line) and other power lines. The induced voltage produced in this way will interrupt, malfunctions of the driver and cause direct damage to the driver.

2. The signal input must use the shield line, and the shielding net should be single point ending.

3. All the connection of controlling signal should use shield wire, and the shielding net should be single point ending.

Send product request

Other supplier products

| AL-937B Auto Label Rewinder | Features ofAL-937B Auto Label Rewinder Label winding machine Automatic speed sync and tension control, without any adjustments. Wind inside ... | |

| Automatic Tape Dispenser | The working principle of tape dispenser: The tape dispenser is also called a belt cutter. It is mainly used to cut the tape up and down the blade,... | |

| Fully Automatic Terminal Crimping Machine | The operation procedure of Full Automatic Crimping Machine 1. The operator must be trained to post the certificate for working;2. Pre-operation re... | |

| BJ-08T Wire Twisting Machine | Product features ofWire Twisting Machine BJ-08T Axis design, while standing! Greatly improve production efficiency LCD backlit display, modern ... | |

| Automaitc Coil Winding Machine | What are the most common problems with automatic coil winding machine and what are the using techniques?There are four common problems with thecoil... |

Same products

| The Ultimate Tool for Bubble-Free Displays | Seller: Shenzhen Wikshu Technology Co. | FORWARD FW-16R Bubble Remover and FW-8R Mini Bubble Removal Machine removes screen OCA bubbles du... | |

| Precision CNC Lathe With Conjoined Oblique Rail Cutter Tower | Seller: Zhejiang Guoyu CNC Machine Tool Co., Ltd. | Technical Characteristics: 45° slant bed base structure, with strict aging treatment, smooth ... | |

| Rail Welder A Frame aligners railway welding tools | Seller: 834406 | 产品描述 A型车架 A-Frame 是一种导轨对准器,可精确对准要焊接的导轨。该设备在焊接操作期间将导轨固定到位。 | |

| 2 parts fluid mixing dispenser 2 component dosing epoxy PU silicon rubber vacuum system | Seller: 824681 | What is the difference between 2K AB adhesive materials manual potting machine and robot pottingm... | |

| Horizontal Machining Center | Seller: Xilong (Shanghai) Machine Tool Co., Ltd. | Horizontal Machining Center parts can automatically finish four sides milling, boring, drilling, ... |