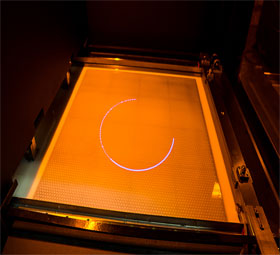

PFM1500 Automated vacuum casting system

It adopts Germany imported Rietschle vacuum pump, ultimate vacuum to ensure complete defoaming; the inner tank selects 5mm thick stainless steel plate to effectively prevent rust and easy to clean; specially selects the aviation plug connection line and uses imported sealing glue to effectively guarantee Equipment is airtight.

Using a rapid part or a CNCed model as a master mold, a high-strength silicone mold is produced under vacuum, then to clone the same replica as the prototype. A silicone mold can replicate about 20 products. The processing speed is more than ten times that of CNC, the processing cost is as low as ten or even dozens of times compared with CNC, which greatly improves production efficiency and greatly reduces the development cost, cycle and risk of direct tooling.

The mold size is up to 1500mmX 1200 mm X 1200 mm, which can efficiently realize the copying of large complex workpieces in small batches production, help to examine the appearance and structural performance of the products, and avoid the risk of direct tooling.

The soft molds after solidification molding are all transparent or translucent, have good tensile strength, and are easy to cut and shape.

According to the specific application requirements of the customer, it provides multiple configuration customizations such as vacuum pump configuration, liner material, and operation mode (automatic/manual).

Back profile:

With our automated , you will get free access to equipment usage training, 3D printing prototype production training, post-treatment process solutions, and lifetime technical support to help optimize production and maximize profit.

Send product request

Other supplier products

| What is 3D Printing Service? | 3D printing technology is a collective term for a series of rapid prototyping technologies, the basic principle of which is laminated manufacturing... | |

| PFM800 Automated Vacuum Casting System | It adopts Germany imported Rietschle vacuum pump, ultimate vacuum to ensure complete defoaming; the inner tank selects 5mm thick stainless steel pl... | |

| Injection Mould Service | What is a Mold? In industrial production, various types of presses and special tools mounted on the press are used to produce metal or non-metal ma... | |

| Reverse-Engineered Service | What is Reverse Engineering? Reverse engineering Chinais to obtain the point cloud data of the physical model by using the three-dimensional digita... | |

| Vacuum Casting Services | What is the Vacuum Casting? The vacuum casting technology which uses prototype (SLA laser rapid prototyping piece, CNC products) to make silicone m... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | Seller: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | Seller: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| Ceramic Core Injector | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Ceramic Core Injector is designedspecifically for producingcomplex, high quality and high pre... | |

| Wax Injection Machine | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Wax Injection Machine is used to make wax patterns in the investment casting process with mid... | |

| Automatic Dewaxing Autoclave | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | Dewaxing Autoclave is specially designed for removing the wax patterns in the ceramic shell. Ins... |