Look For CNC Machining Metal Materials

As an advanced cnc metal machining factoryin Guangdong, China, Flourish Legend is committed to providing high-quality and precision custom parts and component solutions. With years of experience and excellent technical capabilities, we can machine various metal materials, including aluminum, stainless steel, brass, steel, copper, titanium, and more. These materials are widely used in various industries, including automotive manufacturing, electronic devices, medical instruments, aerospace, and more.

Types of CNC Metal Materials Available

CNC Machining Aluminium

Flourish Legend specializes in CNC machining of aluminum alloys. With advanced technology and precision equipment, we ensure high precision and stringent quality standards in manufacturing complex aluminum alloy parts and meeting your fine machining requirements. We strive to deliver premium and durable aluminum alloy products that meet your highest expectations.

CNC Machining Stainless Steel

CNC machining stainless steel can provide precision products for various industries, the durability, corrosion resistance and aesthetics of stainless steel products make them the first choice in industries such as aerospace, automotive and medical. Use CNC technology to meet complex designs and tight tolerances, create complex product shapes, and improve product performance while maintaining the inherent strength and longevity of the material.

CNC Machining Tool Steels

CNC machining of tool steel enables high-precision part manufacturing. With its excellent hardness, wear resistance and heat resistance, tool steel is widely used in fields such as molds, knives and mechanical parts. CNC machining technology ensures the consistency of precision design and tight tolerances to manufacture components such as blades and molds. This process enables the fabrication of complex shapes, improving performance and reliability in harsh environments while maintaining the strength and durability of the material. Whether in the automotive, aerospace or manufacturing industries, CNC machining of tool steels provides the key support for the production of high-quality parts.

CNC Machining Mild Steels

CNC machining of low carbon steel allows for the precise manufacture of a wide variety of parts. Low carbon steel is suitable for automotive, electronics, construction and other fields due to its good machinability, weldability and strength. CNC technology ensures high precision and consistency to produce components such as bolts and bearings. This process enables the complex shape of the product, improving the performance and reliability of the product in a variety of environments, while maintaining the toughness and durability of the material. Whether in applications such as precision machinery, structural components or home appliances, CNC machining of low carbon steel provides key process support for the manufacture of high-quality parts.

CNC Machining Titanium

Titanium is widely used in aerospace, medical and sports equipment due to its excellent strength-to-weight ratio, corrosion resistance and biocompatibility. CNC technology ensures precision and consistency to produce parts such as bone implants and aircraft engine components. This process enables the creation of complex shapes, improving product performance and reliability in harsh environments, while maintaining the lightweight and durable properties of the material. Whether in the manufacture of medical devices, aerospace components or high-performance equipment, CNC machining of titanium plays a key role.

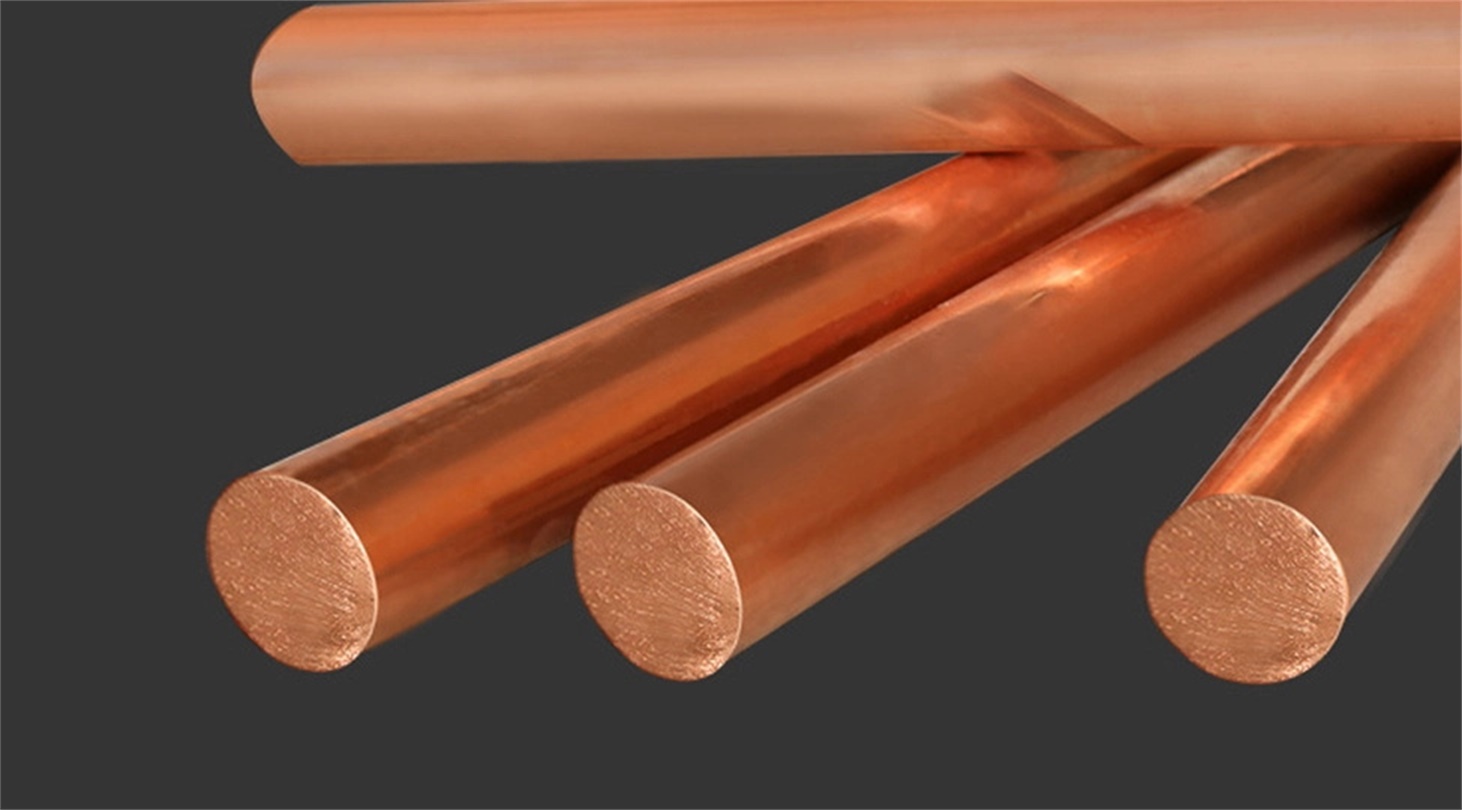

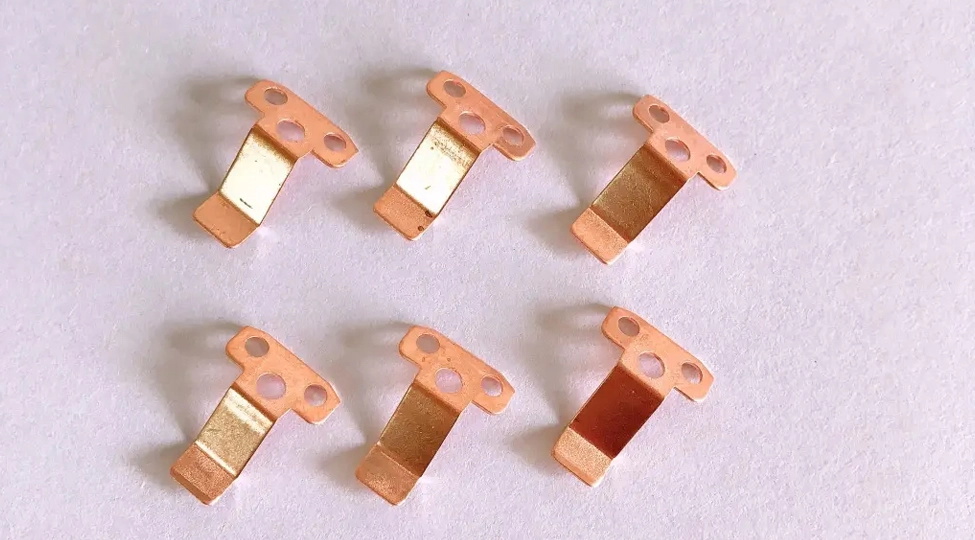

CNC Machining Copper

Copper is widely used in the fields of electronics, communication and industrial equipment because of its good electrical conductivity, thermal conductivity and corrosion resistance. The use of CNC technology can ensure precision and consistency in the production of various components such as electronic connectors, heat sinks, etc. This process allows for the fabrication of complex shapes, improving product performance and reliability in different environments, while maintaining the superior properties of the material. Whether in electronics manufacturing, machining or energy transmission, CNC machining of copper plays a key role.

How is Metal Machining Performed Using CNC?

What Are The Common Applications Of Cnc Machining Metal Parts?

- Construction and Engineering: steel structures, door and window frames, railings, etc.

Several Factors Need To Be Considered When Selecting The Appropriate Metal Type For CNC Machining

When selecting the appropriate metal type for customized CNC machining, several factors need to be considered:

01

Requirements

02

Properties

03

Difficulty

04

Cost

05

Reliability

06

Standards

FAQs About CNC Machining Metal Materials

Q

Why Do People Prefer CNC Machining Metal Over Other Methods?

A

There are several reasons why people prefer CNC (Computer Numerical Control) machining of metals over other methods:

Overall, CNC machining of metals offers advantages such as high precision, efficiency, capability for complex geometries, flexibility, and visualization simulation. This makes it a widely adopted machining method in modern manufacturing. It can meet increasingly high product quality requirements, improve production efficiency, reduce costs, and promote innovation and customization.

Q

How Is Metal Machining Performed Using CNC?

Q

How Is Metal Machining Performed Using CNC?

A

CNC (Computer Numerical Control) is a commonly used precision machining method for metals. Here are the general steps involved in metal machining:

Please note that the above steps represent a general metal machining process, and specific requirements and steps may vary in actual operations. The specific machining methods and procedures can differ based on the specific workpiece and machining needs.

There are many metal machining manufacturers, but we are one of the best choices for you.

For more information about customized cnc machining, please feel free to contact us!

Send product request

Other supplier products

| Stainless Steel Machine Taps | Customized machine taps for stainless steel, through precise processing technology and high-quality stainless steel materials, ensure the corrosi... | |

| Rectangular Stainless Steel Watch Case | Flourish Legend specializes in customized stainless steel watch case manufacturing, offering professional customization of various mechanical, qu... | |

| CNC Turning | Flourish Legend is equipped with cnc turning center manufacturerswith decades of experience. We specialize in various turning manufacturing work, i... | |

| CNC Machining ABS | For 14 years, Flourish Legend has become one of the professional precision abs precision machining llcof abs machining partsin China, no matter how... | |

| CNC Machining Copper | Flourish Legend showcases the outstanding advantages of copper machining! Supported by advanced equipment and professional technical talents, we pr... |

Same products

| MTL5582B MTL Intrinsically Safe Isolator 5500 Series RTD-RTD Isolator | Seller: 840499 | MTL 5500 Intrinsically Safe Isolators Resistance Isolator MTL5582B MTL4582B - MTL5582B RESISTANC... | |

| CNC Machining Services | Seller: Shenzhen Flourish Legend Limited | Flourish Legend is a high precision machining manufacturercertified with ISO 9001:2015. With an e... | |

| Copper Stamping | Seller: Shenzhen Flourish Legend Limited | Flourish Legend Precision Hardware Copper Stamping - We have been specializing in production and ... | |

| CNC Turning | Seller: Shenzhen Flourish Legend Limited | Flourish Legend is equipped with cnc turning center manufacturerswith decades of experience. We s... | |

| CNC Machined and Molded Robotic Components Manufacturer | Seller: Shenzhen Flourish Legend Limited | High Production Efficiency Superior Quality Automated Equipment Precision Machining Low Cost ... |