Active rotary lime kiln to produce metallurgical lime used in electric arc furnace steelmaking

Active rotary lime kiln to produce metallurgical lime used in electric arc furnace steelmaking

rotary lime kiln

metallurgical lime

electric are furnace steelmaking

Active rotary lime kiln

rotary lime kiln to produce metallurgical lime

Active rotary lime kiln used in electric arc furnace steelmaking

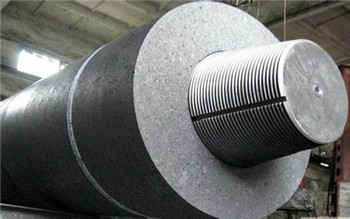

Kiln Active lime rotary kiln is composed of cylinder, gears, support device, kiln liner and kiln tail sealing equipment, hood of kiln head and alkene material device etc. Active Lime rotary kiln as a heating device is a high-quality steel processed, is supported on the support device by tyer, and there is hydraulic pressure catch wheel on the first or some gear in order to control the turning of cylinder. Gearing gyrate according to process-required rotating speed by ring gear in the middle of cylinder.

Because of the need of installation or maintenance, the bigger Active lime rotary kiln has auxiliary gears, which makes cylinder gyrate more slowly. To prevent cold air come in and dust overflow, the reliable kiln tail and hed sealing equipment are installed on feed and discharge end. The most common are Cement clinker Rotary kiln, etc., more models to choose.

Feature of SINOM’s active lime rotary kiln:

Rotary kiln design should meet the following requirements:

1, The specification of the rotary kiln should meet the demand of burning system output and it should be determined comprehensively combining the raw materials or fuel condition and the configuration situation of the preheater, decomposition furnace and the cooling machine.

2, The proportion of preheater kiln and pre-decomposing furnace(L/D) had better to be 11-16.

3, The slope of preheater and decomposition furnace should be 3.5%-3.5%; In the terms of rotation speed, the decomposition furnace should be 3.0-3.5 r/min and the preheater should be 2.0-2.5 r/min. The speed changing range should be1:10.

4, The cooling of rotary kiln burned into cylinder should adopt forced air cooling.

5, The main motor of rotary kiln should adopt steepless variable speed motor and should be installed auxiliary transmission and emergency power supply.

Working principle of active lime rotary kiln:

The limestone is 1150 degrees Celsius in the preheater kiln gas heated to 900 degrees Celsius, about 30% decomposition,and then the hydraulic push the push rod into rotary kiln. The limestone in rotary kiln roasts decomposition theory for CaO and CO2. Decomposition generates into the cooler lime and will be cooled in the cold air cooling to 100 degree Celsius eduction. The heat to 600 degrees Celsius heat of air into the kiln and the mixed fuel gas. The cold wind confirmed by waste gas again into the bag filter induced fan, then the drained to the chimney. Discharge of the cooler the lime vibrating feeder, chain conveyor and fight a pattern lift machine and belt into the lime library. According to the needs of user to determine whether screening process classification.

◆Preheater without pushing rod

For more detailed technical information, please feel free to contact us. Sinom at sinomgroup dot com

Contact informaiton:

Tel:

Mobile:

Web:

Send product request

Other supplier products

| Online automatic bar counter for rebar rolling mill | SINOM’s bar counter can achieve automatic counting online. The system adopts the technical paths of video capture, image processing, multi-ob... | |

| China high quality graphite electrode manufacturer for submerged arc furnace | China high quality graphite electrode manufacturer for submerged arc furnace submerged arc furnace graphite electrode manufacturer high quality gr... | |

| square copper mould tube manufacturer/supplier for CCM | square copper mould tube manufacturer/supplier for CCM square copper mould tube copper mould tube supplier copper mould tube manufacturer square co... | |

| high speed steel rolls for bar rolling mills and cold strip mills | high speed steel rolls for bar rolling mills and cold strip mills bar rolling mills cold strip mills high speed steel rolls high speed steel rolls ... | |

| RP/SHP/HP/UHP graphite electrode for EAF steelmaking manufacturer | RP/SHP/HP/UHP graphite electrode for EAF steelmaking manufacturer EAF steelmaking UHP graphite electrode UHP graphite electrode manufacturer graphi... |

Same products

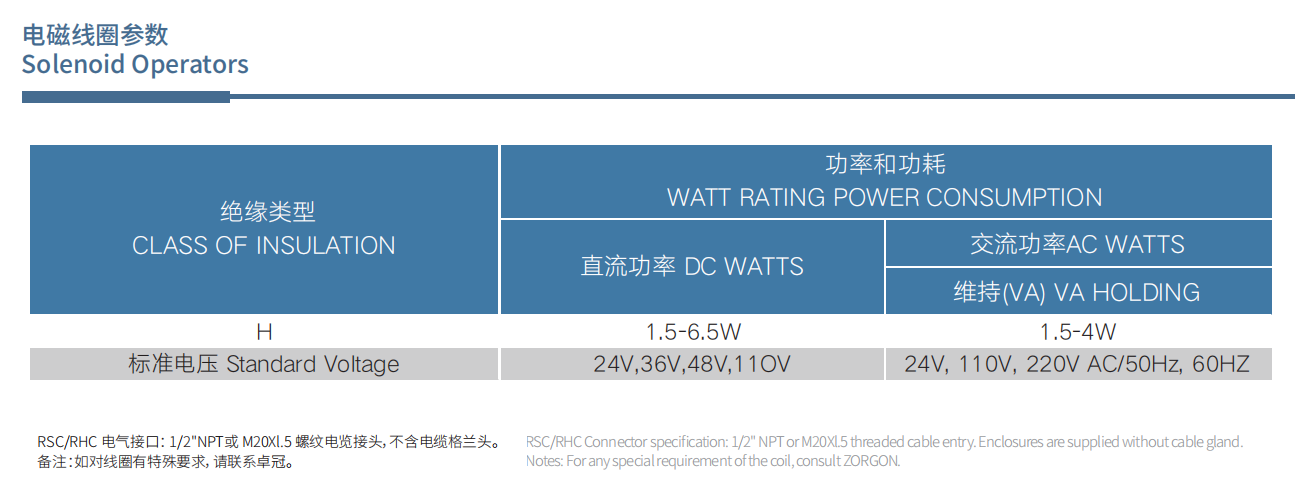

| SERIES 151 solenoid valve | Seller: ZORGON | 151 series solenoid valve, solenoid valve are suitable for use in conjunction with pneumatic cont... | |

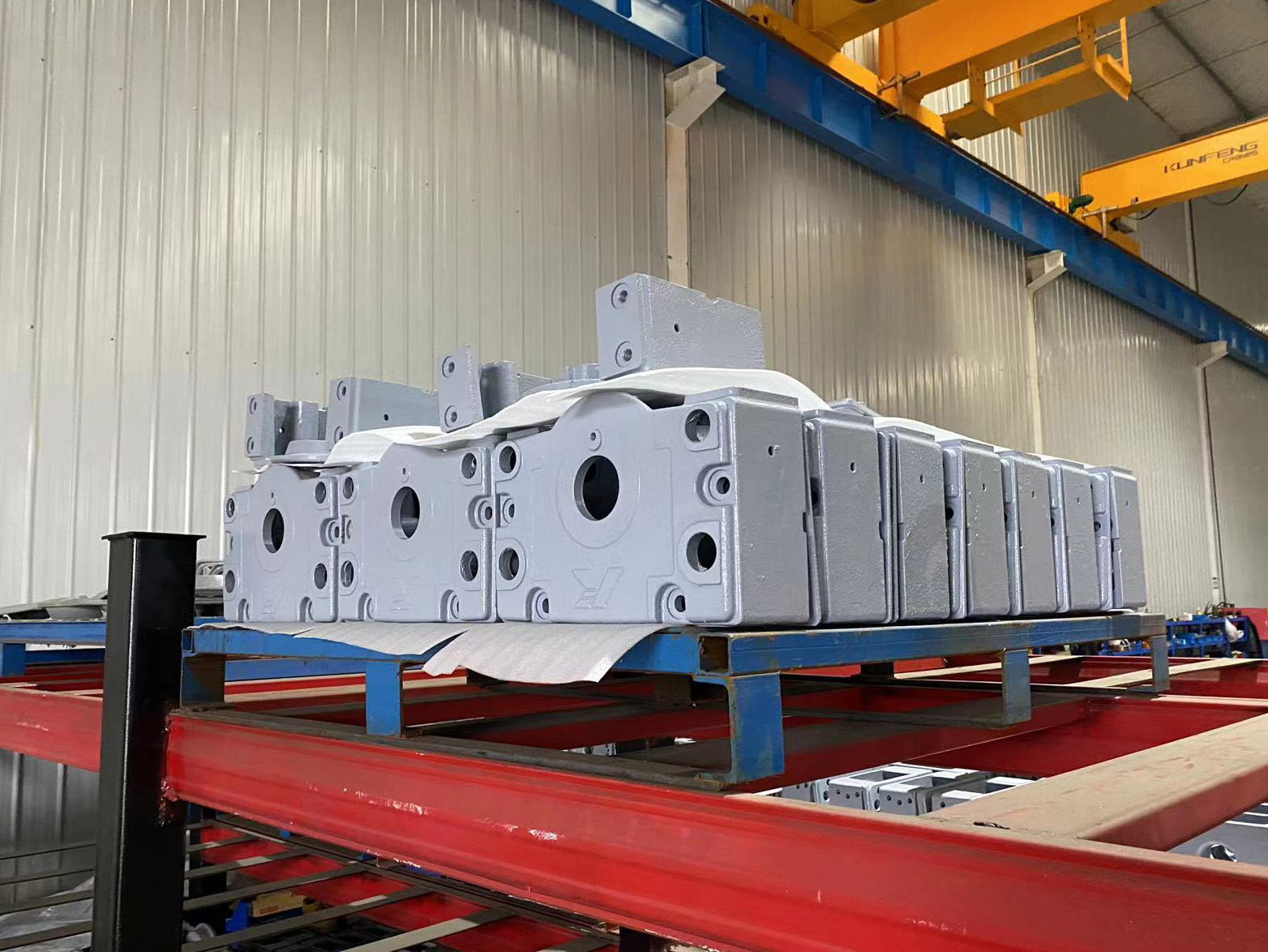

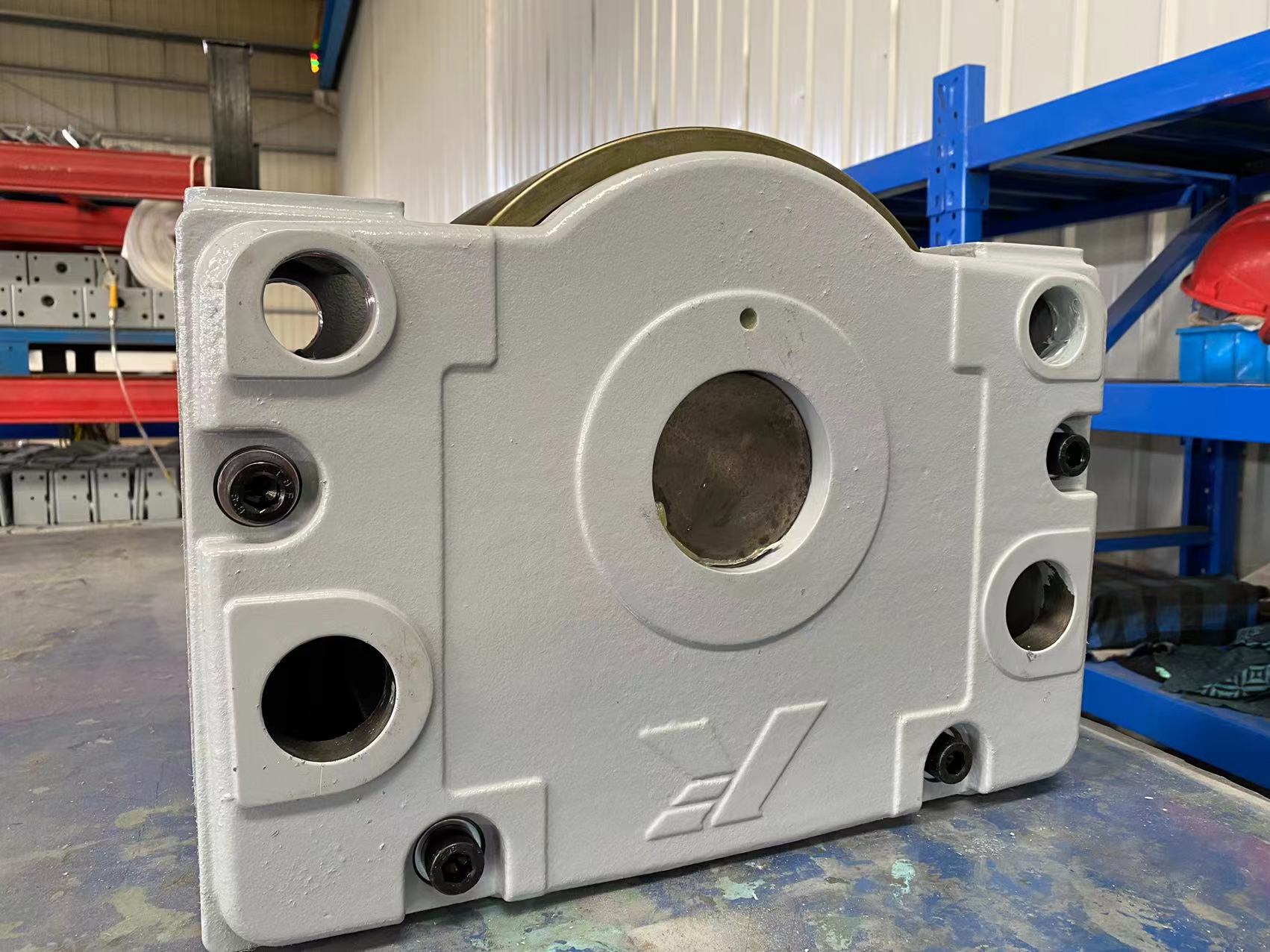

| Wheel Block Drive System with Gear Motor for Crane | Seller: KunFeng Heavy Industry (Suzhou) co., LTD. (KF CRANE) | A complete driven wheel system includes the wheels, electric AC induction brake motor, gearbox, e... | |

| DRSA Wheel Block System | Seller: KunFeng Heavy Industry (Suzhou) co., LTD. (KF CRANE) | KUNFENG® DRSA Wheel Block System features large load capacity with compact dimension, wheel d... | |

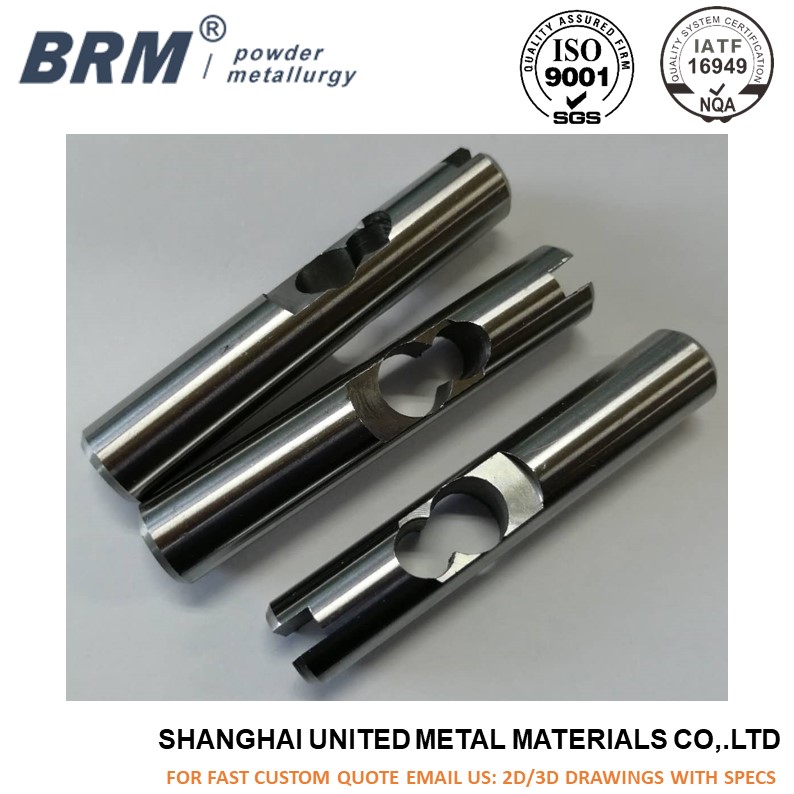

| CNC machining precision steel parts | Seller: BRM metal injection molding | BRM metal injection molding specializes in Powder Metallurgy for all industries with more than 20... | |

| Precision CNC machining platen of rotor for automotive transmission parts | Seller: BRM metal injection molding | Product Specifications /Features : Feedstock– Injection molding – De-binding – ... |