Active rotary lime kiln to produce metallurgical lime used in electric arc furnace steelmaking

Active rotary lime kiln to produce metallurgical lime used in electric arc furnace steelmaking

rotary lime kiln

metallurgical lime

electric are furnace steelmaking

Active rotary lime kiln

rotary lime kiln to produce metallurgical lime

Active rotary lime kiln used in electric arc furnace steelmaking

Kiln Active lime rotary kiln is composed of cylinder, gears, support device, kiln liner and kiln tail sealing equipment, hood of kiln head and alkene material device etc. Active Lime rotary kiln as a heating device is a high-quality steel processed, is supported on the support device by tyer, and there is hydraulic pressure catch wheel on the first or some gear in order to control the turning of cylinder. Gearing gyrate according to process-required rotating speed by ring gear in the middle of cylinder.

Because of the need of installation or maintenance, the bigger Active lime rotary kiln has auxiliary gears, which makes cylinder gyrate more slowly. To prevent cold air come in and dust overflow, the reliable kiln tail and hed sealing equipment are installed on feed and discharge end. The most common are Cement clinker Rotary kiln, etc., more models to choose.

Feature of SINOM’s active lime rotary kiln:

Rotary kiln design should meet the following requirements:

1, The specification of the rotary kiln should meet the demand of burning system output and it should be determined comprehensively combining the raw materials or fuel condition and the configuration situation of the preheater, decomposition furnace and the cooling machine.

2, The proportion of preheater kiln and pre-decomposing furnace(L/D) had better to be 11-16.

3, The slope of preheater and decomposition furnace should be 3.5%-3.5%; In the terms of rotation speed, the decomposition furnace should be 3.0-3.5 r/min and the preheater should be 2.0-2.5 r/min. The speed changing range should be1:10.

4, The cooling of rotary kiln burned into cylinder should adopt forced air cooling.

5, The main motor of rotary kiln should adopt steepless variable speed motor and should be installed auxiliary transmission and emergency power supply.

Working principle of active lime rotary kiln:

The limestone is 1150 degrees Celsius in the preheater kiln gas heated to 900 degrees Celsius, about 30% decomposition,and then the hydraulic push the push rod into rotary kiln. The limestone in rotary kiln roasts decomposition theory for CaO and CO2. Decomposition generates into the cooler lime and will be cooled in the cold air cooling to 100 degree Celsius eduction. The heat to 600 degrees Celsius heat of air into the kiln and the mixed fuel gas. The cold wind confirmed by waste gas again into the bag filter induced fan, then the drained to the chimney. Discharge of the cooler the lime vibrating feeder, chain conveyor and fight a pattern lift machine and belt into the lime library. According to the needs of user to determine whether screening process classification.

◆Preheater without pushing rod

For more detailed technical information, please feel free to contact us. Sinom at sinomgroup dot com

Contact informaiton:

Tel:

Mobile:

Web:

在线联系供应商

Other supplier products

| copper crusher for bullet testing,Crusher type pressure gauges | copper crusher for bullet testing,Crusher type pressure gauges Crusher type pressure gauges are used to determine the maximum pressure in the barre... | |

| China largest airport conveyor system equipment supplier | China largest airport conveyor system equipment supplier SINOM supply the airport baggage conveyor system to airports worldwide. The airport belt c... | |

| contiunous galvanized line equipment with Primetals technology supplier,process-optimized hot-dip galvanizing lines supplier | contiunous galvanized line equipment with Primetals technology supplier,process-optimized hot-dip galvanizing lines supplier we supply process-opt... | |

| electric arc furnace used for melting quality carbon and alloy steel | electric arc furnace used for melting quality carbon and alloy steel electric arc furnace electric arc furnace for melting quality carbon electric ... | |

| hot wire rod rolling mill production line | SINOM GROUP CO., LTD. has maintained the leading position in China in the aspect of wire rod process, equipment and technology, possessing superior... |

Same products

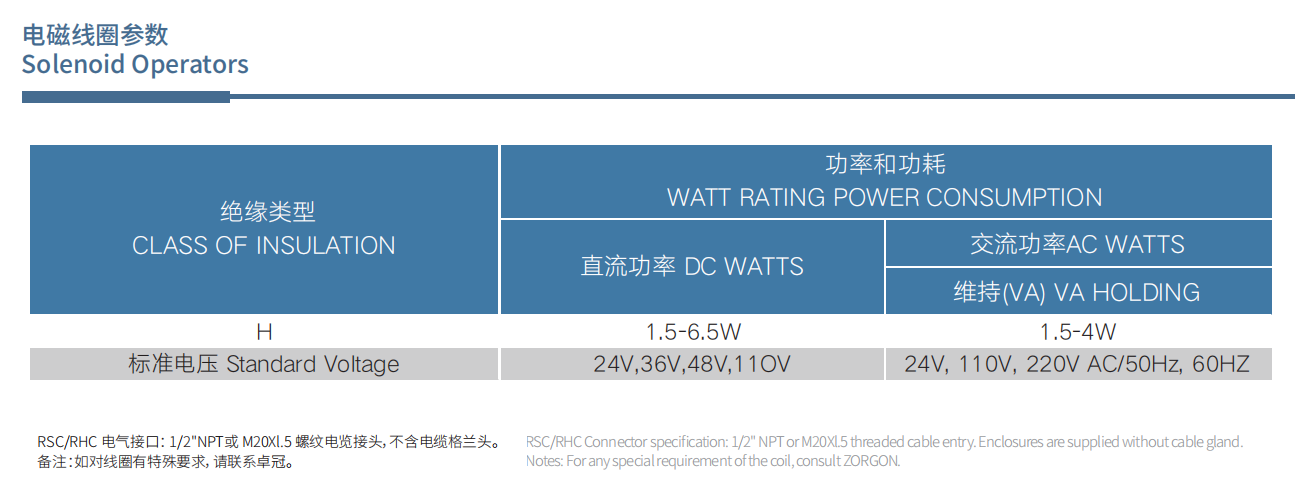

| 151系列电磁阀 | 卖方: 卓冠 | 151系列电磁阀,在流程生产中电磁阀很多时候是与气动调节阀和活塞执行机构配合使用,这时电磁阀只起辅助功能 但作用十分重要。尤其是在工艺生产连锁中,电磁阀具有很重要的作用,如气源有故障时工艺阀的开... | |

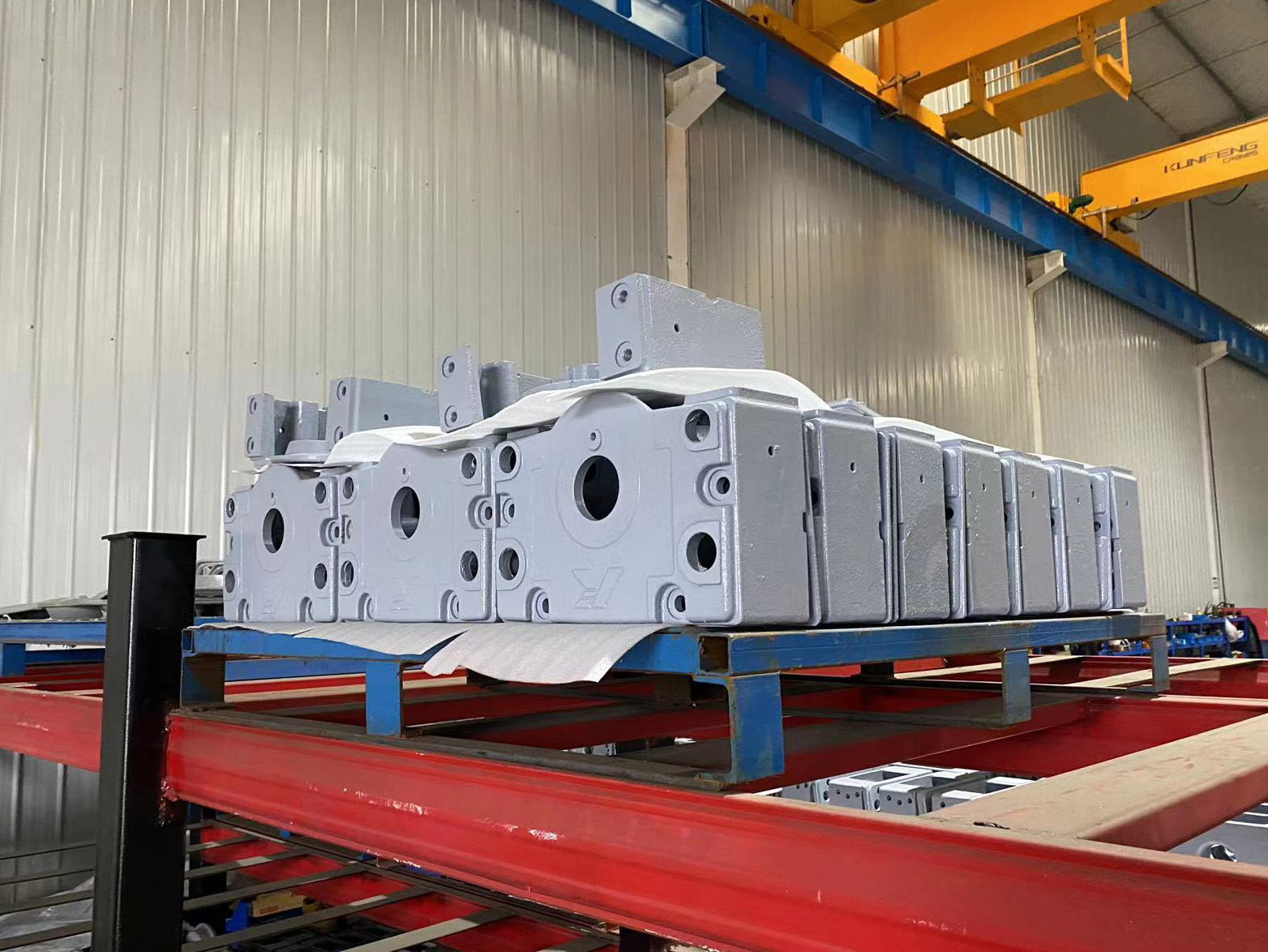

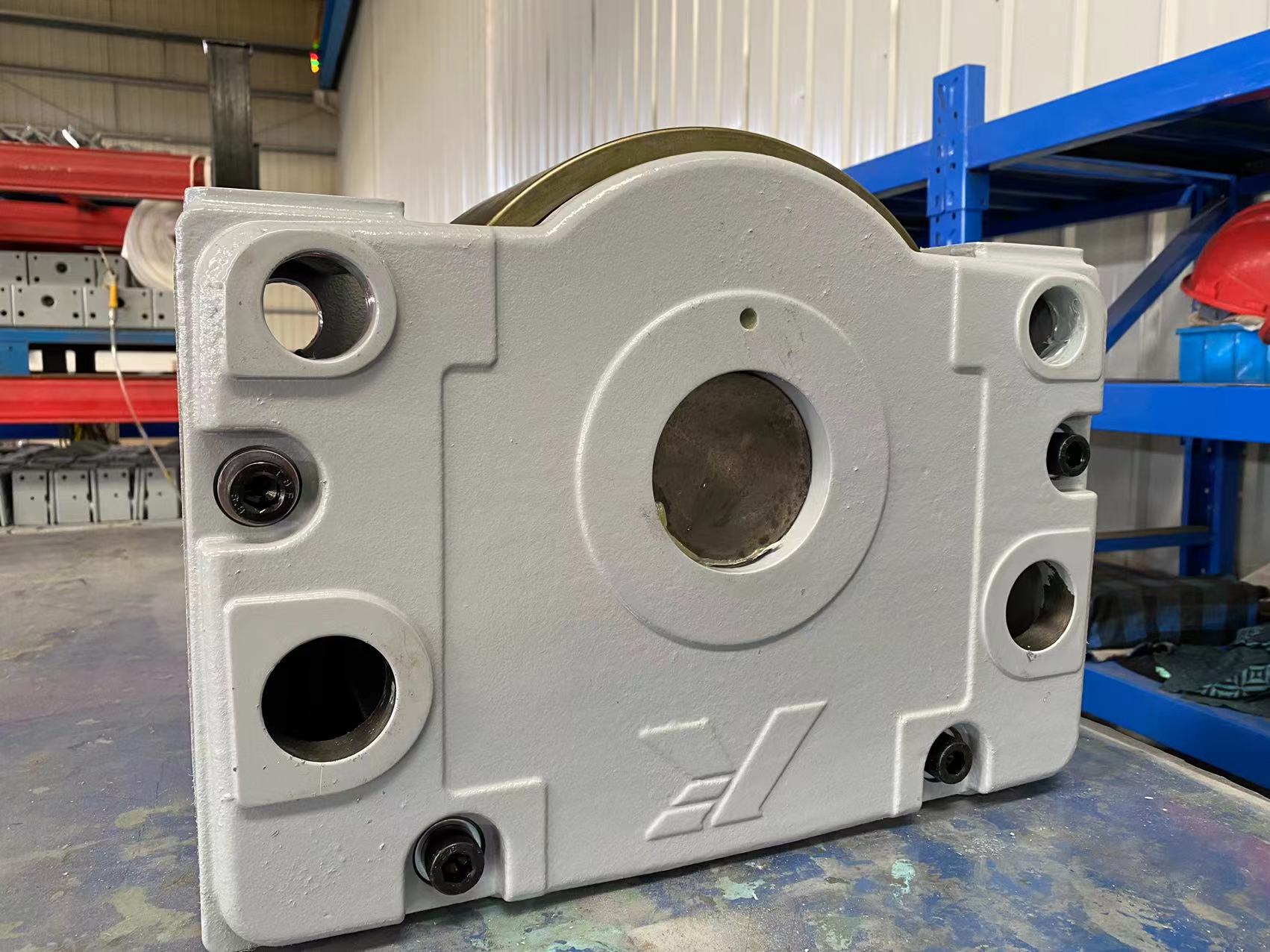

| Wheel Block Drive System with Gear Motor for Crane | 卖方: 昆峰重工(苏州)有限公司(KFCRANE) | A complete driven wheel system includes the wheels, electric AC induction brake motor, gearbox, e... | |

| DRSA Wheel Block System | 卖方: 昆峰重工(苏州)有限公司(KFCRANE) | KUNFENG® DRSA 轮组系统具有负载能力大、尺寸紧凑、轮径大的特点,确保为相应的应用选择合适的单元。 特征: • 优质可靠的服务 • 应用多样性:用于移动桥梁... | |

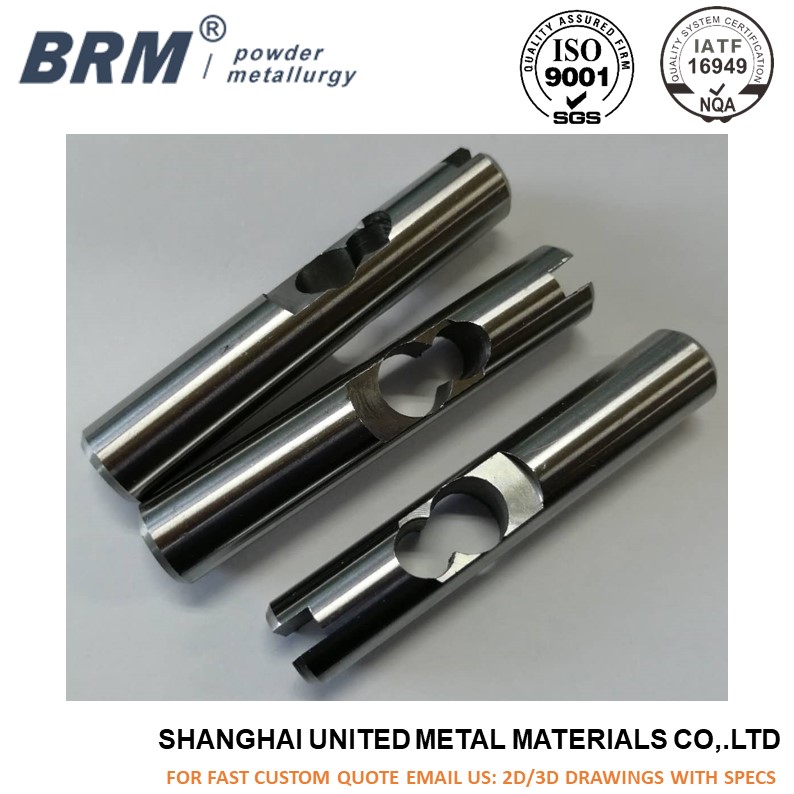

| CNC machining precision steel parts | 卖方: 上海秉瑞金属材料有限公司 | BRM metal injection molding specializes in Powder Metallurgy for all industries with more than 20... | |

| Precision CNC machining platen of rotor for automotive transmission parts | 卖方: 上海秉瑞金属材料有限公司 | Product Specifications /Features : Feedstock– Injection molding – De-binding – ... |