LDT-L200 Ladle Lining Laser Thickness Gauge

LDT-L200Ladle Lining Laser Thickness Gauge

Overview

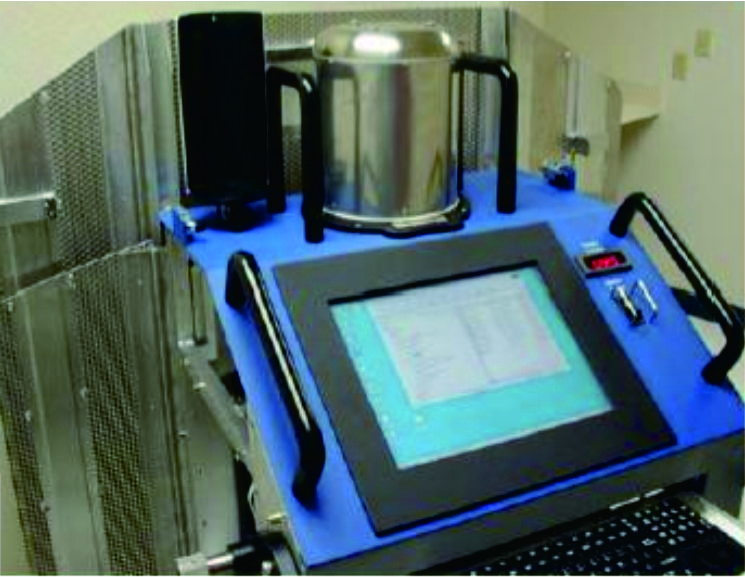

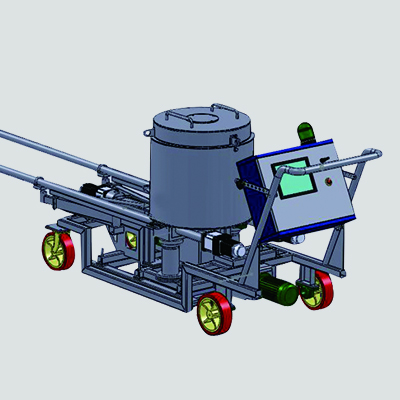

LDT-L200 is a new generation ofladlelining thickness gauge launched by our company. The system equipment emits a pulsed laser beam to the lining surface of the ladle, and receives the returned laser light to measure its flight time. Thenthe system equipmentcalculates the distance between the equipment and the target point according to the transmission speed of the laser. During measurement, the user pushesthe equipmentto a certain position on the platform in front of theladle,and the equipmentcan start to scan and measure the target area of theladleafter the equipment performs rapid self-positioning.

The detection principle

The measurement speed of LDT-L200 can reach up to 2,000,000 points per second, and each scan can obtain distance data of more than 1.5 million points. The actual surface curveof the entireladlelining can be obtained by combining the measurement data of different positions.

During the measurement, the laser head of the equipment rotates at a certain step angle to rapidly change the angle of the pulsed laser beam. Within1minute, the three-dimensional surface contourof theladlelining can be formed, and the thickness information of the furnace lining can be obtained through coordinate conversion calculation. The measurement accuracyup to±2mm.

In order to accurately calculate the thickness of the lining in the ladle, the measuring head of the laser thickness gauge is installed on the ladle repairing platform. By moving the swivel arm for hoisting, the laser scanning head is moved to the intersection position during measurement, and the relative position of the laser head to the ladle mouth will be calculated during installation. Through mathematicalmodeling, a complete 3D figure of the thickness of the entire ladle lining can be displayed after laser scanning

The main components

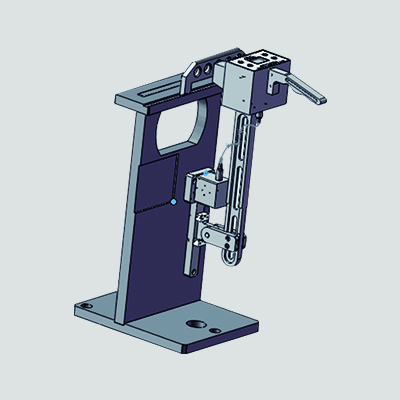

1. Laser measuring head

2. Fixed laser thickness gauge host

3. Optical fiber communication

4. Cooling circulation system

The technical indexes

Laser reproducibility: ±2mm

Laser accuracy: ±2mm

Local fastest measurement time: <15s

Positioning time: <30s

Full image measurement time: <1min

The highest measurable lining temperature: 1850℃

Measuring distance: 0.5-25m

Actual points are measured per frame: >1500000 points

Eye-safe laser: Class 1 laser product (doesn't hurt the eyes)

The parameter of laser measuring head

Measurement principle:According to the flight time and speed of the laserto calculate the distance

Laser reproducibility: ±2mm

Laser accuracy: ±2mm

Scan rate: 2000000 points/second

Measuring angle: vertical ±40°, horizontal 360°

Maximum measurement temperature: 2200℃

Working temperature: -20℃-80℃

Cooling method: Integrated liquid cooling system, IP64 grade protection

Laser wavelength: 1550nm (near infrared)

Send product request

Other supplier products

| WGS-L020 Flat Steel/Ribbon Iron Width Measuring System | WGS-L020Flat Steel/Ribbon Iron Width Measuring System Overview Whether the width and thickness of the flat steel/ribbon iron width measuremen... | |

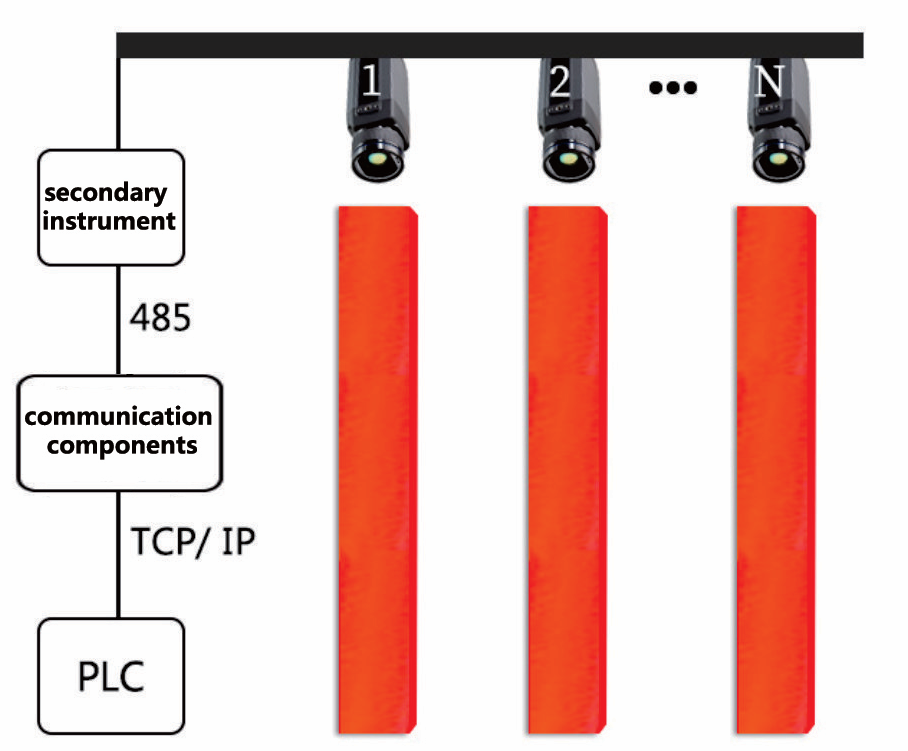

| On-line Billet End Continuous Temperature Measurement | ZST-P100 On-line Continuous Temperature Measurement of the Billet End Overview Thesystem aimsat the continuous temperaturedetectionof theproducto... | |

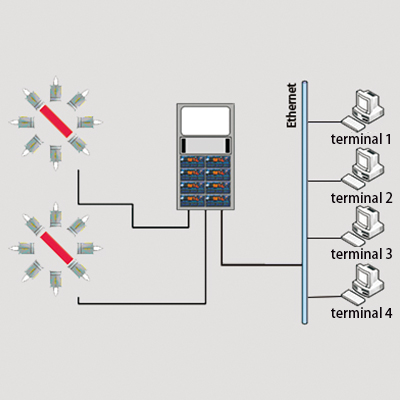

| LDC-X200 Laser Diameter Measuring System | LDC-X200 Laser Diameter Measurement System Overview The non-contact diameter measuring system, is mainly used in the measurement of the outer d... | |

| MDC-K120 Slab Mold Taper Measuring Instrument | MDC-K120Slab Mold Taper Measuring Instrument Overview The taper of the narrow face of the mold has an important influence on the quality of t... | |

| MAC-G320 Automatic Mold Flux Feeding Machine | MAC-G320Automatic Mold Flux Feeding Machine Overview MAC-G320automaticmoldfluxfeeding systemis a new generation product ofautomaticaddingmoldfl... |

Same products

| Lifting Beams Adjustable Lifting Beam | Seller: Hebei Connect Trading Co.,Ltd | Structure: I Beam For Lifting type and streamline form. Working Load Limit: 2 Ton to 50 Ton A... | |

| Replacement of PALL HC8304FAN16H Hydraulic filter element | Seller: Xinxiang Saya Filters Co., Ltd | Product Advantages: 1. Using glass fiber from the American HV brand as the filter layer, the fil... | |

| Argo V2.1260-06 Hydraulic Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Performance characteristics of Argo V2.1260-06 Hydraulic Filter Replacement: 1. Good filtration p... | |

| Eaton Internormen Hydraulic Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Product Description: The filter elements have the characteristic on high pressure collapse resis... | |

| Sullair / Air Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Ayater air filter Introduction: ● Air Filter Element is a critical part of Compressor, made of hi... |