MAC-G320 Automatic Mold Flux Feeding Machine

MAC-G320Automatic Mold Flux Feeding Machine

Overview

MAC-G320automaticmoldfluxfeeding systemis a new generation product ofautomaticaddingmoldflux, which isindependently developed by WuhanCenterRise M&CEngineering Co., Ltd. According to different steel grades,casting speed, vibration and other process parameters,thenthe systemcananalyze and calculatethe accuratemold fluxaddition amountthrough intelligent software. Then the systemsendsout signals to control themold fluxaddition process andmold fluxaddition amount, and designsappropriate nozzles and propellers according to the fluidity of molten steel in the mold and the ductility of moldflux. After the system setting is completed,there isno manual intervention is required. Itcompletely replaces the whole process of manual addition of moldflux, and realizes the automation ofmold fluxaddition.

The features of the system

1. The system automatically controls the amount, process and timeofadding mold fluxaccording to the process requirements of automatic moldfluxaddition, so as to maintain the physical state of the moldfluxand prevent it from being broken.

2. The user can match different parameters according to actual needs, so as to change the length of themold fluxfeeding time and the amount ofmold flux,which cansuitfor the use of different sections and differentcasting speeds.

3. Thecastingspeed signal isusedand the amount ofadding mold fluxcan be automatically adjusted according to thecastingspeed. The mold flux can be addedtimely andevenly,which can improve the quality of the billetand reduce labor intensity.

4. The time is controlled by PLC, no manual intervention is required. The adjustment is very convenient.It hasmanual, automatic,local and remote control modes.

5. The system has reliable performance and simple structure, and can be adapted to powder and granular moldflux.

6. It has a special anti-blocking nozzle and backflushing design to overcome the phenomenon of pipeline blockage.

7. Strong operability, simple and convenient maintenance, and low maintenance cost.

8. It can maintain theevendistribution of thefluxlayer in the mold.

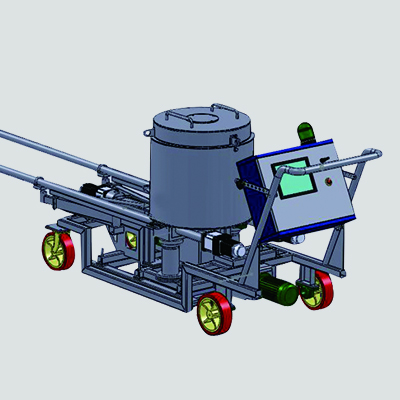

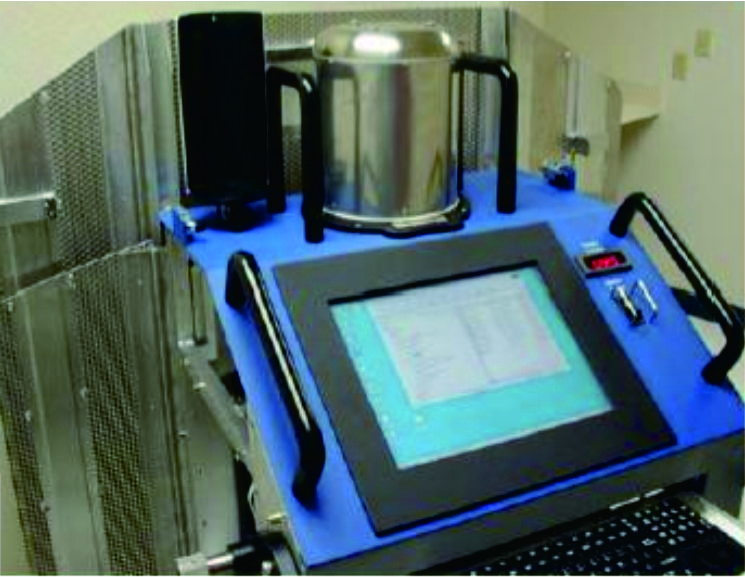

The composition of the system

The system consists of feeding trolley, feedingbucket, swing arm andfeeder motor, swing arm transmission device, PLC and control equipment.

1. The feeding trolley is the support and walking equipment of themoldfluxfeeder.The basic equipment of theadding moldfluxmachineis installed on the feeding trolley. At the same time, the trolley can easily make themold fluxfeeder walk to the working position or the parking position.

2. The feedingbucketis a device for holding moldflux. The moldfluxis pre-filled in the feedingbucketand is evenly output through the feeder. The feedingbucketis provided with alarm contact ofmold fluxlevel limit..

3. The swing arm and thefeedermotorform a feeding and conveying device. The moldfluxis evenly transmitted to thefeed openingat the front end of the swing arm through the screwdistributing devicecontrolled by the motor. Then the mold flux can be used for mold distribution.

4. PLC and control equipment adjust and control themold fluxfeeding speed, operation mode and control mode of themold fluxfeeding machine, and realize various control modes and rates.

5. The swing arm transmission device controls the reciprocating motion of the swing arm according to the size of different molds, so that themold fluxis evenlydistributedin the mold.

The technical parameter

Mold width: 500-2000mm

Mold thickness: 100-500mm

Type: screwconveyingtype moldfluxfeeding machine

Heating method: stirring electric heating

Arrangement location: on the pouring platform (with its own wheelsto move)

Adding capacity: 0.5~7.5L/min, continuously adjustable feeding tube

Moldingfluxstorage tank: ~125 L, with material level detection and alarm

Control mode: local/remote control,automatic/manual mode

Moldingfluxtype: granularfluxor powderflux

fluxadding method: spiral swing addingflux

Casting speedinterlock: yes

Mouldsize setting: yes

Signal transmission: DP/Industrial Ethernet

Send product request

Other supplier products

| LDT-L200 Ladle Lining Laser Thickness Gauge | LDT-L200Ladle Lining Laser Thickness Gauge Overview LDT-L200 is a new generation ofladlelining thickness gauge launched by our company. The sys... | |

| Mold Surface Cladding Detection Equipment | Mold Surface Cladding Detection Equipment Overview: This product is a new type of moldcopper platesurfacecladdingdetectionequipment. The equipment... | |

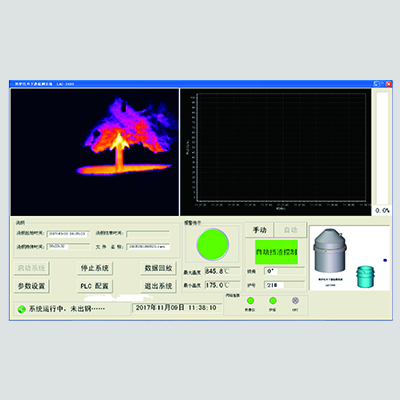

| LAG-S400 Infrared Converter Slag Detection System | LAG-S400Infrared Converter Slag Detection System Overview The infrared converter slag detection system uses a far-infrared thermal imager to mo... | |

| MDC-K400 Square and Round Billet Taper Measuring Instrument | MDC-K400Square and Round Billet Taper Measuring Instrument The product description The square, rectangular and round billet taper measuring i... | |

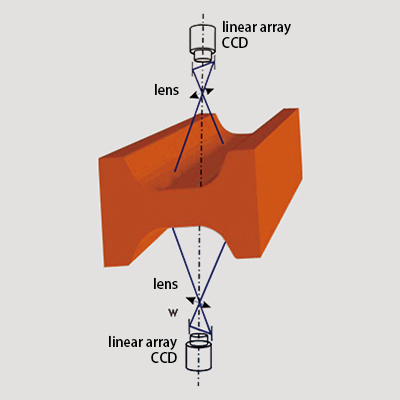

| ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD) | ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD) Overview The surface quality inspection of high temperatu... |

Same products

| Lifting Beams Adjustable Lifting Beam | Seller: Hebei Connect Trading Co.,Ltd | Structure: I Beam For Lifting type and streamline form. Working Load Limit: 2 Ton to 50 Ton A... | |

| Replacement of PALL HC8304FAN16H Hydraulic filter element | Seller: Xinxiang Saya Filters Co., Ltd | Product Advantages: 1. Using glass fiber from the American HV brand as the filter layer, the fil... | |

| Argo V2.1260-06 Hydraulic Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Performance characteristics of Argo V2.1260-06 Hydraulic Filter Replacement: 1. Good filtration p... | |

| Eaton Internormen Hydraulic Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Product Description: The filter elements have the characteristic on high pressure collapse resis... | |

| Sullair / Air Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Ayater air filter Introduction: ● Air Filter Element is a critical part of Compressor, made of hi... |