Factors for Molding Rate of Coal Briquette Plant

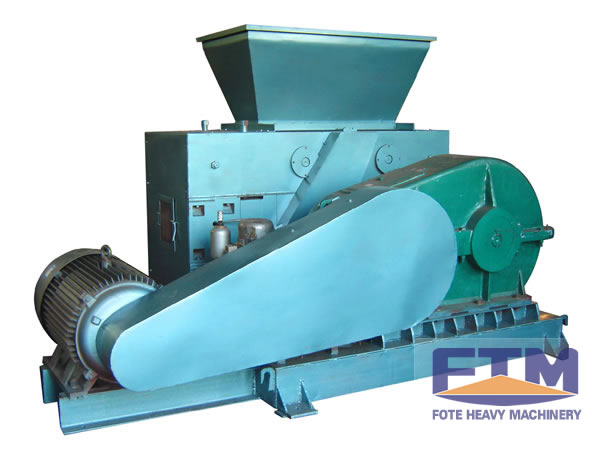

With wide application ranges, the coal briquette machine can be used to suppress materials like coal powder, iron powder, coking coal, aluminite powder, scrap iron, scale, carbon powder, charcoal powder, mineral slag, gypsum, tailings, sludge, kaolin, activated carbon and coke breeze, etc. The finished products of coal briquette machine can be widely used for industries like refractory material, power plant, metallurgy, chemical engineering, energy, transportation and heat supply, etc.

Except for the wide application ranges, the finished products are energy-conserving, environmental-friendly and easy for transportation. Therefore, the finished products of coal briquette plant are of great economic and social benefits. For many users of coal briquette press machine, they are more concerned about the molding rate. Then, what factors can influence the molding rate of coal briquette plant? The following content will give you answers.

The first factor is the water content in raw materials. If the water content in raw materials is great, the bonding between materials and press rollers is easy to be caused. As a result, the balling rate of coal briquette press is easy to be influenced. The second factor is the amount of foreign matters in raw materials. During the suppressing process, foreign matters inside will influence the bonding force between raw materials. As a result, the finished products will become loosened. The molding effect will be much poorer.Fote briquetting machine manufacturersincerely welcomes you to come for site visit and inspection!

Click the website to know theprice of coal briquette press! Leave messages on website for more information.

Fote Heavy Machinery:

Fote Official Email:

Send product request

Other supplier products

All supplier products

Working Performance of FTM Jaw Crushing Plant

Featured in the high working efficiency, strong working capacity and convenient maintenance, jaw crushing machine can meet the demands of different...

Classifications of Hammer Mill Crusher in Market

For the sand aggregates produced by the hammer mill crusher, they can be widely used for industries like mining, cement, chemical engineering, buil...

Briquetting Plant/Large Briquetting Plant

Introduction to Large Briquetting Plant

Major equipments: compound crusher, feeder, horizontal mixer, briquetting machine and dryer. Briquettes pla...

Role of Stone Crushing Plant for Sand Making

Along with the economic development, more and more countries in the world have been running the way of urbanization. To realize the urbanization, i...

Points Related With Work of Hydraulic Cone Crusher

The matching of feeding size should be suitable. Service life of hydraulic cone crusher will be seriously influenced if materials are too coarse or...

Same products

YZH WHEN1510 Stationary Pedestal Rockbreaker Boom

Seller: Shandong Yirun Foundation Engineering Co., Ltd

Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its...

YZH WHEN1410 Stationary Pedestal Rockbreaker

Seller: Shandong Yirun Foundation Engineering Co., Ltd

YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr...

YZH WHEN 1300 Stationary Pedestal Rockbreaker

Seller: Shandong Yirun Foundation Engineering Co., Ltd

The Features of the WHEN 1300 Stationary Pedestal Rockbreaker:

Intelligent Multi-Mode Control: S...

WHE1500 Pedestal Breaker Boom Systems

Seller: Shandong Yirun Foundation Engineering Co., Ltd

The Features of WHE1500 Pedestal Breaker Boom Systems:

The WHE1500 Pedestal Breaker Boom System ...

WHEN1850 boom breaker

Seller: Guangxi YZH Machinery Equipment Co.Ltd

A high-performance crushing equipment is crucial in the secondary crushing process of industries ...