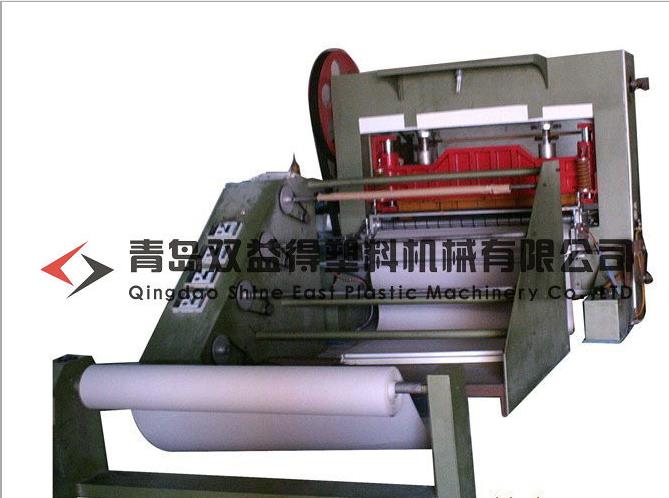

PVC plastic sheet production line

The extruded plastic plate unit is equipped with a conical twin-screw extruder and the corresponding wave plate forming machine, traction auxiliary machine and cutting machine. It can continuously produce UPVC color weather-resistant flame-retardant plastic wave plates for construction. The machine has stable plasticizing performance, compact structure and high degree of automation.

This production line is used for the continuous production of PC, PE, PP plastic plates. The products are widely used in building decoration, advertising layout, road noise, sound insulation and packaging.

It can replace carton as packing box, light weight, high strength, moisture-proof and anti-corrosion.

Finished plate width: 1220-2100mm, thickness: 2-12mm

Extruder: The special design of the screw and the advanced temperature control system ensure that the plastic is well plasticized and stable in high output.

Screen changer: The hydraulic quick screen changer is selected to make the screen change process fast and effective; the double station and special sealing structure ensure the stable work of the screen changer.

Mould: The mould is made of high-quality alloy steel, with a highly active throttling device, so that the distribution pressure of the material flow in the die is uniform; the differential adjustment of the upper and lower dies ensures the uniform thickness of the upper and lower walls.

Vacuum setting table: The setting system is equipped with a fast heat exchange refrigeration system, which is effectively staggered with the vacuum system and is distributed sequentially. This distribution ensures the accuracy of the setting.

The vacuum system consists of two independent subsystems. Each subsystem is equipped with multiple three-point fixed cycle vacuum lines. Each fixed cycle carries a vacuum adjustment system and a vacuum display system, so that the vacuum on the surface of the plate is uniform and stable. .

Traction machine: The first and second groups of tractors are distributed. The first group of tractors is of high power, large reduction ratio, and multi-roller type. It has excellent low-speed running performance and large traction. Pull out. The second group of tractors is destressed. It is also equipped with a trimming device to ensure the effective width of the plate and the quality of the edge of the plate.

Other supplier products

All supplier products

Same products