Medical Plastic Parts

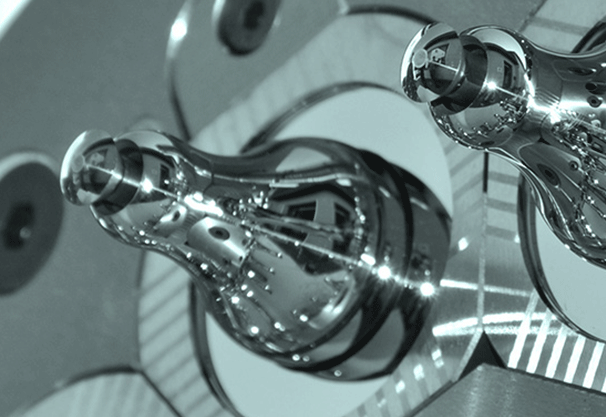

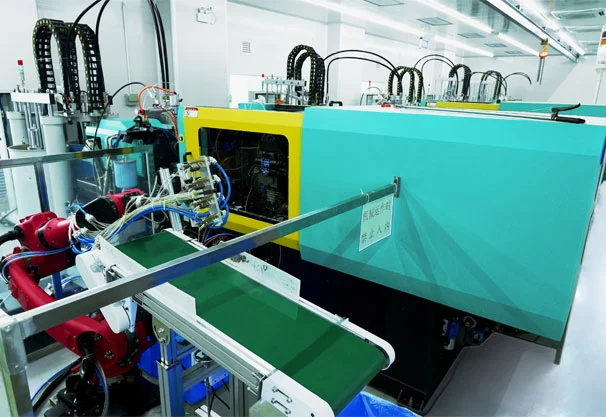

To be a qualified medical plastic components manufacturer, the most advanced technology and continuous compliance and certification are the pillars of success. Medical progress is advancing by leaps and bounds. We can't imagine how things are now being developed so quickly. It helps improve everyone's quality of life. Our cleanroom facilities are for medical plastic parts and liquid silicone rubber molding. They are all ISO certified to 13485 and 9001. We've been providing the best medical plastic parts production molding solution to BD for over 5 years. Please don't hesitate to contact us for competitive medical plastic solutions like Medical disposables, Medical devices, Medical plastic parts, Medical packaging, and Medical instruments.

Medical Plastic Parts Production Process

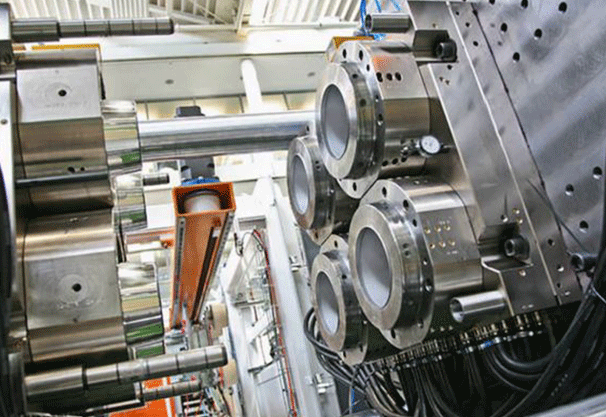

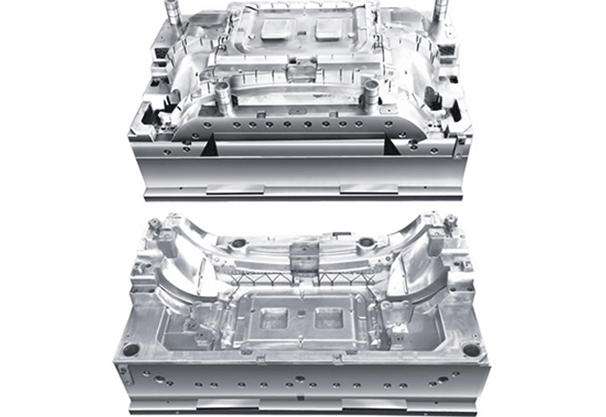

As experienced injection molding partner will be value-add compared with price. When injection molders understand and focus on each development stage from mold design and mold flow analysis to process monitoring and quality control, OEMs know that scientific molding will ensure accuracy in processes and production. Therefore, production process control will plays important role in medical plastic parts molding.

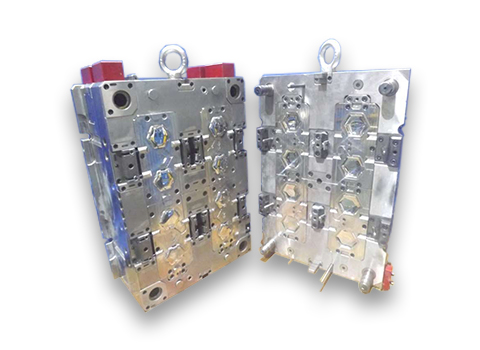

Cooperated Engineering Work

A mature injection molding partner is committed to early project participation. The adjustment engineering team provides an opportunity for both parties to agree on which dimensions are process-sensitive and which dimensions can be adjusted through tool modifications. Define and prioritize non-sensitive and tight tolerance dimensions to ensure that time and energy are properly allocated throughout the production process.

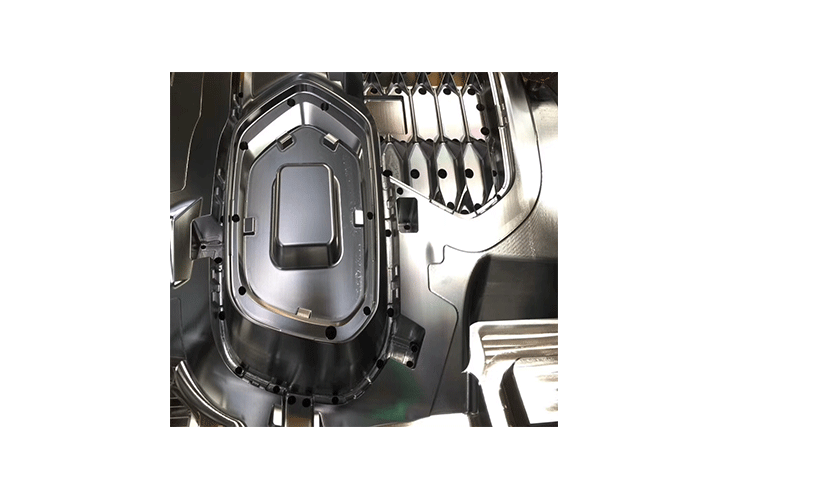

Medical Plastic Parts Molding Operation Control

Medical equipment requires separate verification of parameters and settings during the medical plastic parts injection molding process. Molders incorporate this requirement into their processes so they don’t confuse these two processes and waste project time on settings that can be adjusted according to equipment requirements, rather than verifying actual parameters (e.g. time, temperature) And pressure).

For more information about injection molding in chinaand medical grade plastics injection molding, please feel free to contact us!

Send product request

Other supplier products

| Clean Room Injection | ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability With more... | |

| Custom Metal Machining Parts | Packson provides our customers a various CNC machining services to our customers, including milling, turning, grinding, drilling and more. Our t... | |

| One-stop Injection Molding Service Expert | For more than 15 years, Packson Mold has become an excellent manufacturer that is enabled to make parts with high tonnage and large size thanks to ... | |

| 2K Injection Molding | Multi-component molding is a highly efficient and cost-effective technology that enables the molding of custom plastic parts using two or three pla... | |

| 2K Injection Molding | ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability 2k inject... |

Same products

| JY-160S2 Standard Plastic Injection Machine | Seller: Dongguan Jieyang Machinery Co., Ltd | Straight screw ejected assembly. Two(three)-phase temperature, ejected speed, backing pressure a... | |

| Silicone Rubber Injection Molding | Seller: Packson Mold Co.,Ltd | Packson's state-of-the-art facilities consist of a 1000㎡ certified clean room, which is equipped ... | |

| Prototype Injection Mould | Seller: Packson Mold Co.,Ltd | Packsonmold is a company that provides high-quality prototype services, including 3D printing, CN... | |

| Precision Injection Molding | Seller: Packson Mold Co.,Ltd | At Packson, we specialize in manufacturing custom precision mold partsand machined parts that mee... | |

| Overmolding Injection Molding | Seller: Packson Mold Co.,Ltd | Overmoldingmold is made of overmolding injection molding processwhich is a special injection mold... |