Auto Balance Shaft Multi-station Automatic Quenching Machine

Produced by: Heatking Induction Technology (Shiyan) Corporation Shanghai Shangpin Electrical Equipment Co., ltd

All supplier products

Auto Balance Shaft Multi-station Automatic Quenching MachineThis series quenching machine is fit for heating quenching of various shaft parts,Website:, especially for the quenching and tempering of engine intake shaft, balance shaft and exhaust shaft, several quenching parts with different diameters are completed at different stations, and the three stations can work automatically at the same time, or only one station works automatically or manually. The loading and unloading is completed by the stepping loading mechanism automatically without manual operation. When changing workpiece varieties, it only needs to change the corresponding processing program and install the suitable inductor. The machine adopts SINUMERIK840DSL CNC system to control the workpiece transfer, induction coil location, workpiece rotation, quenching, tempering and loading and unloading automatically. The processing technical parameters can be set and adjusted in the processing screen Real-time monitoring of working situation and processing parameters and real-time recording of processing parameters and quantity are used for access at any time. The electrical control system is linked with heating power supply to realize quenching automation.HKHP50/3 Automatic and Horizontal Three-station Shaft Quenching Machine Functions and FeaturesThe machine bed is weld and processed after aging treatment, so the machine has good rigidity, stability and shock resistance.With the fully-automatic loading and unloading function, the machine can finish loading and unloading of the machine or between stations automatically.Each station can heat and hardening independently, so different station can be chosen for different workpieces. The inductor adopts quick-changing structure, so when changing the inductor, it only needs to loosen the screw and install the inductor, then the water and electricity will be provided.Clamping claw owns auto centering function, which is reliable, convenient and durable. When changing the workpieces, there is no need to adjust the claw, and with the positive pressure gas inside the claw, it can prevent the water and dust from entering the claw, so as to keep its long service life.When changing different workpieces, in length direction, No.1 and No.2 stations only need to adjust the center position, and No.3 station needs to adjust the driving head according to the work-piece length and scale.The machine is enclosed by high-quality stainless steel plates, and it is equipped with hinged doors and hardened glass inspection windows; it is beautiful and convenient for maintenance.The machine is equipped with pressure protection mechanism, and when the air pressure is over low, the machine will stop running automatically.ConfigurationThe equipment consists of three-station quenching machine, 3 sets of IGBT power supplies, quenching liquid circulation cooling device and purified water circulation cooling device (including low-pressure cooling system 0.1-0.2MPa, high-pressure cooling system 0.6-0.8MPa), electrical control system and compressor chiller, etc.The workpiece clamping, positioning, centering, and loading and unloading pushing are all carried out pneumatically, and the stepping mechanism is driven by clicking.The workpiece rotation is driven by servo motor, to ensure when the semi-circle shaft is quenching, the positioning device required by workpiece loading and unloading has the function of stopping at a fixed angle.The transformer load quenching moving is controlled by servo motor, led by linear guide rail and driven by imported ball screw, to ensure the feeding accuracy.The power head moving is led by linear guide rail and driven by cylinder.With the temperature control system for cooling water and quenching liquid, the temperature of cooling water and quenching liquid can be controlled automatically.The energy-saving quenching transformer can reduce the load loss.The compensation capacitor is made in France, which is small in volume, stable in performance, and convenient to adjust.The heating power supply adopts the international advanced IGBT transistor variable frequency power supply, which has the advantages of high frequency, low fault rate and 100% startup success rate. The power supply owns complete protection function and faults diagnosis and warning function. There are various power channels and analog quantity control interfaces inside the power supply, which makes it convenient to adjust the processing power. All the safety indicators of the frequency conversion power supply conform to the national standard, and the safety protection level is IP65. The power cabinet is fully closed, and equipped with inspection illumination and sockets.The perfect fault-tolerant function effectively improves the reliability when the machine running in high-efficiency situation. The operation is simple, only one worker can finish it.

All supplier products

Send product request

Other supplier products

| Oblique Roller Quenching Machine | Oblique Roller Quenching MachineThe machine is obliquely vertical type,Website:, with an angle of 70 degrees to the horizontal plane. The machine a... | |

| Vertical Inductor Moving Quenching Machine | Vertical Inductor Moving Quenching MachineThis series quenching machine is mainly suitable for long shaft parts and disc parts induction quenching... | |

| HKTP Transistor Induction Heating Power Supply | HKTP Transistor Induction Heating Power Supply (Medium/ Supersonic /High Frequency)HKTP series transistor medium-frequency,Website:, high-frequency... | |

| Auto Balance Shaft Multi-station Automatic Quenching Machine | Auto Balance Shaft Multi-station Automatic Quenching MachineThis series quenching machine is fit for heating quenching of various shaft parts,Websi... | |

| KGPS Series Thyristor Medium Frequency Power Supply | KGPS Series Thyristor Medium Frequency Power SupplyBy adopting international advanced technology,Website:, and combined with our innovation, our co... |

Same products

| FNAC-28 2 IN 1 Type-C USB Tester Voltage Current Power Meter | Seller: Phonefix | FNIRSI FNAC-28 Multifunctional 2 in 1 Type-C USB Tester Digital Voltmeter Ammeter Amperimetor Vol... | |

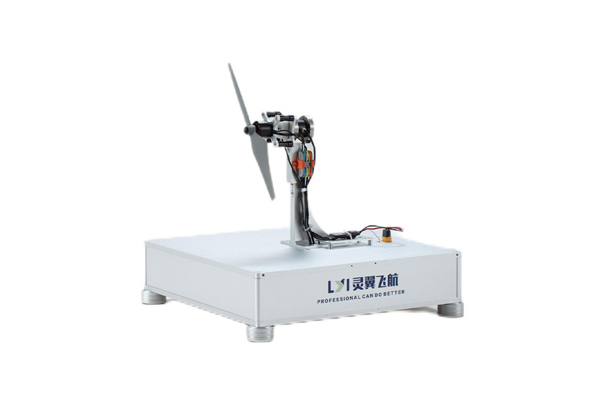

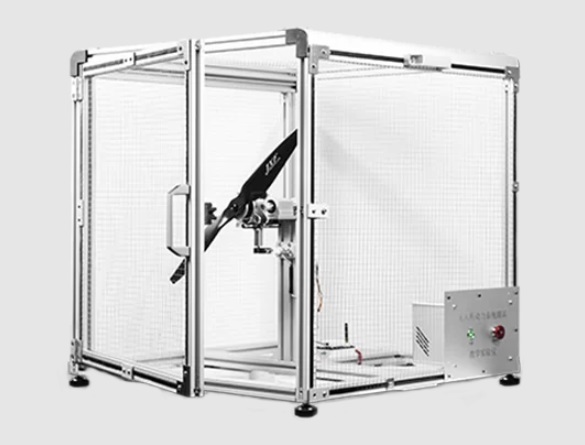

| WF-EDU-02 Motor & Propeller Test Kit | Seller: Wing Flying Technologies Co., Ltd | WF-EDU-02 Motor & Propeller Test Kit Product Description Motor & Propeller Test Kitsare... | |

| WF-EDU-01 Motor and Propeller Test Kit | Seller: Wing Flying Technologies Co., Ltd | WF-EDU-01 Motor and Propeller Test Kit Product Description Suggested Propulsion system ... | |

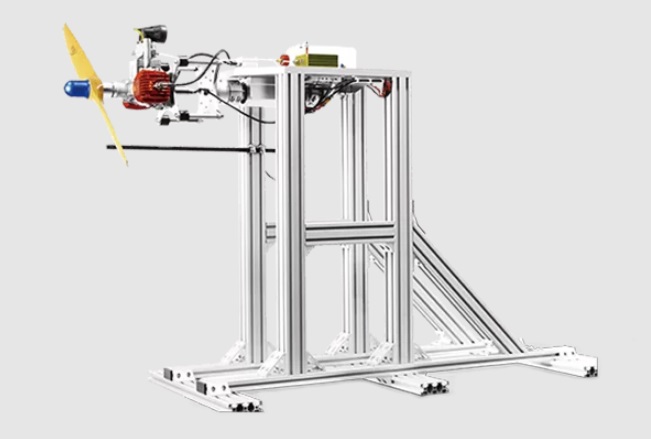

| WF-EN-50 Engine Test Bench | Seller: Wing Flying Technologies Co., Ltd | Suggested Engine 110cc-350cc Engine Max Hanging Type Engine 20kg ... | |

| WF-EN-15 Engine Test Bench | Seller: Wing Flying Technologies Co., Ltd | WF-EN-15 Engine Test Bench Product Description Suggested Engine 110cc Engine ... |