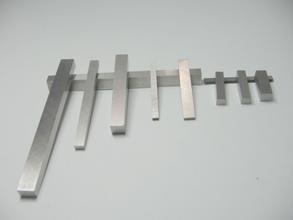

Samarium Cobalt

Samarium CobaltSamarium Cobalt magnet is a high performance low temperature coefficient permanent magnet made of samarium and cobalt and other rare earth elements. The main advantage of SmCo magnets: high magnetic capability,Website:, excellent temperature stability, superior corroding-resistance and oxideizing-resistance. SmCo magnet is widely used in motors, watch, transducers, instruments, positional detector, generators and radar etc.The characteristic and application of SmCo magnets:1. SmCo permanent magnet has high magnetic energy product and high coercive force. Its properties are better than AlNiCo, ferrite permanent magnet. Its maximum magnetic energy product is up to 239KJ/m3 (30MGOe), which is three times than AlNiCo8 permanent magnet, eight times than ferrite permanent magnet (Y40). So the permanent magnetic component made from SmCo permanent magnets is small, light and stable in property. It is widely used in electronic acoustic and telecommunication appliance, electronic motor, measure meter, peg-top, electronic watch, microwave appliance, magnetic machine, sensor and other static or dynamic magnetic routes.2. The curie temperature of the SmCo permanent magnet is high and its temperature coefficient is little. So it is suitable for using at 300 high temperature.3. SmCo permanent magnet is hard and bristle. Its rigidity strength, tensile and press strength are low. So it is not suitable for framework.4. The main ingredient of SmCo permanent magnet is metal Cobalt (Co 99.95%). So its price is high.5. SmCo permanent magnet needn't to be coated because it is difficult to be eroded and oxidized.Physical properties of SmCo magnetsCurie Temp.Tc800~850Coefficient of Thermal ExpansionC1/~8 10-5DensityDg/cm38.3~8.5C1/~11 10-5Recoil Permeabilityrec 1.00~1.05Rigidity StrengthN/m2~1.5 108Max. Working TemperatureTmax350Compress StrengthN/m2~8 108Electrical Resistivity .Cm~8.6 10-5Tensile StrengthN/m2~3.5 107Vickers HardnessHv 500~600Young s ModulusN/m2~1.2 1011Thermal Conduct Rate W/mK~12Magnetization Field HakA/m1600Manufacturing MethodsSmCo magnets are manufactured in the following forms:Sintered - fine SmCo powder is compacted in a die and then sintered, fusing the powder into a solid material. There are two forms of pressing: die pressing (which involves a hard die into which the powder is placed and then pressed), and isostatic pressing (involving a special "rubber" die into which powder is placed and then pressed with equal force in all directions on the powder). Die pressed parts are smaller than isostatically pressed parts. Although the magnetic properties of isostatically pressed parts are higher, the uniformity of magnetic characteristics is usually lower than that of die pressed parts. Sintered parts usually need some finish machining in order to meet final tolerances.Compression Bonded - this is a technique whereby a special form of SmCo powder is blended with a plastic carrier material, die pressed and then heated. Parts made in this way can be of complex shapes and come off the tool with close tolerances, requiring no further finish machining. They have lower energy products than sintered materials.Typical magnetic properties of SmCo magnetsMaterialGradeRemanenceCoercive forceIntrinsic Coercive forceMaximum Energy productCurie TemperatureMaximum Working Temperature BrbHciHc(BH)maxTCTW TKGsKA/mKOeKA/mKOeKJ/m3MGOeCCSmCo (1:5)YX-180.85-0.98.5-9.0620-6487.8-8.YX-200.92-0.969.2-9.6653-7178.2-9.YX-240.96-1.09.6-10.2730-7709.2-9.SmCo (2:17)YXG-240.95-1.029.5-10.2637-7328.0-9.YXG-261.02-1.0510.2-10.5748-7969.4-10.YXG-281.05-0.0810.5-10.8756-7969.5-10.YXG-28B1.02-1.1010.2-11.04205.2-5.6440-5205.5-6.YXG-301.08-1.1010.8-11.07809.8-10.YXG-30B1.08-1.1510.8-11.54205.2-5.6440-5205.5-6.Remark: What we list herein are only typical grades of SmCo magnets. We also could manufacture various magnetic properties according to the customer s requirements.Reference points for Samarium magnets:SmCo magnets are highly prone to chipping and cracking, and specialized machining techniques are required. Press-fit assembly is not recommended because of their brittle nature. The SmCo materials are sensitive to thermal shock and hairline fractures can occur if subjected to thermal shock. Where cosmetic appearance of a magnet is important, this should be specified to us prior to ordering.SmCo magnets are anisotropic, and can only be magnetized in the orientation direction. In general, magnetizing fields of about 35 to 45 kOe are required to saturate SmCo materials. This is not common to produce and large power supplies in conjunction with carefully designed magnetizing fixtures must be used. A special consideration must be given to this when designing complex assemblies if it is intended to magnetize after assembly.Two types of SmCo magnets are SmCo5 and Sm2Co17. The 2-17 composition is also more corrosion resistant and more stable at very high temperature.

Other supplier products

|

|

Ferrite Magnet |

Ferrite Magnet

Ferrite magnet is also called ceramic magnets. The main components of the raw materials are iron oxide,Website:, barium c... |

|

|

Cast AlNiCo Magnet |

AlNiCo magnet are a type of metal alloy, which is derived from Aluminum, Nickel, Cobalt, Iron and a few other elements, such as: Copper, Titanium a... |

|

|

Injection Bonded SmCo Magnet |

Injection Bonded SmCoInjection Bonded SmCo magnet is made by mixing the SmCo magnwetic powder with polymer plastics (such as: PA, PPS, ect.), then ... |

|

|

Samarium Cobalt |

Samarium CobaltSamarium Cobalt magnet is a high performance low temperature coefficient permanent magnet made of samarium and cobalt and other rare... |

|

|

Bonded Ferrite Magnet |

Bonded Ferrite MagnetBonded Ferrite magnet is made by mixing the ferrite powder with polymer plastic (such as PA,Website:, PPS, etc.,), then throug... |

All supplier products

Same products