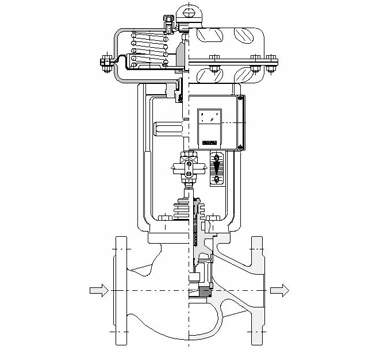

Pneumatic 3-way ball valve

SPTO/SPLO Pneumatic 3-way ball valve is composed of GTX-B series pneumatic rack and pinion

actuators and 3 way ball valve body assembly. It is divided into L-type (SPLO) and t-type (SPTO)

according to different ball structures .SPLO-type is used for changing flow direction of medium,

which can make two perpendicular channels connected or switch direction, SPTO-type can make three

perpendicular channels connected or two of the three channels connected., and change the relative

position of pipe and ball, it can also change direction of fluid in mutually perpendicular pipes and

combined control of shunting fluid and mixing fluid. 3 way ball valve port has small resistance, large

flow coefficient. Different metal and soft seal materials can guarantee reliable conveying and excellent

cutting function at temperature of - 29 ° ~ 45 °.

SPLO/SPTO Pneumatic 3-way ball valve is characterized by compact structure, effective handle,

steady and long lifetime.

It is widely used in industrial control area of petroleum, chemical, metallurgy, electric power, paper,

metallurgy and sewage treatment etc.

Valve Body

Type: Two split 3-way cast ball valve (as shown in figure 1)

Nominal Diameter: DN15,20,25,40,50,65,80,100,150 ,200

Nominal Pressure: GB PN1.6, 2.5, 4.0, 6.3Mpa

ANSI CLASS150, 300

End Connection: Flange GB PN1.6, 2.5, 4.0,6.3 Mpa according to HG20596-97M,FM,

ANSI CLASS150,300 according to ANSI B16.5 RF and HG/T20615-97

Weld type

Socket weld according to ASME B16.4-2005,

Butt weld according to ASMEB16.4-2005

Screw type according to ASMEB16.4-2005

Face to Face Dimension:PN1.6,2.5,4.0,6.3MPa according to GB/T12221-1989,EN558.1:1995,

ISO5752-1982 basic series 1

CLASS150,300 RF according to EN558.2:1995 and ISO5752-1982 basic series 1

Body Material:Please refer to table 1

Bonnet Type:Together with body

Packing Material: V-type compound packing,graphite compound packing,

graphite packing, Operating Temp. (As shown in table 2)

Seal Gasket: Spiral wound gasket, Graphite with metal gasket, Zigzag gasket, Flat gasket.

Specific materials and operated temp. range as shown in table 3.

Packing Gland : Bolts impacted

Paint: Carbon steel shell surface required to paint, stainless steel or copper surface

without paint .

Trim

Ball type: Through-way full port ball, floating ball, ball is divided into L-type (SPLO) and t-type

(SPTO), please refer to figure. 2

Trim material: STD material assembly and operated Temp. shown in table 4

Flow characteristics: Quickly opening

Rotary angle: 90°

Actuator

Type: GTX-B series pneumatic rack and pinion actuators

Material: Cylinder body: extruded aluminum alloy

Caps and piston: die-casting aluminum alloy

Action: DA double acting,

SR spring return, air to open or air to close

Structural Style: Double piston Double air-chamber rack and pinion(DA) , please refer to figure 3,

Double piston Spring return rack-and pinion (SR),please refer to figure 3 and figure4

Air Pressure: double action 0.1~1.0Mpa,

Spring return 0.2~1.0Mpa

Working Temperature: -20℃~+150℃

Angle Rotation Adjustable Scope:90°±4°

Signal Interface:1/8″G,NAMUR1/4″G,NAMUR1/2″G

Dynamic Medium: clear, dry, non-corrosive air and other gas.

Surface Protection: Caps and springs ,Powder epoxy painted,

Cylinder body, anodic oxidation treatment after sand blast.

Standard Configuration with Valve: please refer to table 5

Accessory

Positioner, Filter-regulator valve, Solenoid valve, Limit switch,

Valve position Transmitter, Handwheel, Booster relay, Air control valve, Pneumatic lock-valve, etc.

Performance

Travel time:As shown in table 5

Seat leakage:Metal seal is according to ANSI B16.104 ClassⅣ,ClassⅤ

Soft seal is according to ANSI B16.104 ClassⅥ

Rated CV:As shown in table 5

Allowable pressure differential:As shown in table 6.1-6.4

Figure Size:As shown in figure 5,table 7.1,7.2

Weight of product:As shown in table 7.1,7.2

Special requests

Produced according to the requirements of customers, details as follows:

○Special inspection

Flow characteristic test,material test,low temperature test,steam test,non-damages test

○copper-free treatment

○completely oil-free, water-free treatment

○appointed coating

○special air piping and fitting

○dust and sand proof

○strong corrosion proof

○vacuum service

○stainless steel bolt and nut for exposed parts

○cold area proof

○tropical area proof

○Machining back of flange back

○With Sewage bolt

○Double packing

○Steam jacket

Other supplier products

All supplier products

Same products