Filter Membrane Pore Analysis Tester

Product Introduction:

The pore size and distribution within a filter membrane dictate its filtration efficiency, flow rate, and retention capabilities. A Filter Membrane Pore Analysis Tester provides quantitative data on these critical properties. The most common technique employed is Capillary Flow Porometry, which is based on the principle of displacing a wetting liquid from the pores using a non-wetting gas.

A specimen of the flat filter membrane is placed in a specialized holder or cell that seals the membrane and separates the upstream and downstream sides. The membrane is first wetted with a fluid that completely fills its pores. A non-wetting gas (such as air or nitrogen) is then applied to the upstream side, and the gas pressure is gradually increased. The liquid held in the pores by surface tension prevents gas flow until the applied pressure is high enough to overcome the capillary forces in the largest pore. The pressure at which gas first flows through the largest pore is the bubble point pressure, indicating the maximum pore size.

Meet the standard:

ASTM E1294 ASTM F316

ISO 4003 ISO 15901-2

The instrument is used in laboratories for:

Determining the pore size distribution, bubble point, and mean flow pore size of flat filter membrane materials.

Validating membrane properties against product specifications.

Quality control during the manufacturing of filter membranes to ensure consistency.

Research and development of new membrane materials and structures.

Characterizing membranes used in various filtration applications, including microfiltration, ultrafiltration, and sterile filtration.

Investigating membrane performance issues.

Product Advantages:

Provides objective, quantitative data on the pore structure of filter membranes.

Essential for understanding and validating membrane filtration performance and retention characteristics.

Determines the largest pore size (bubble point), which is a key indicator of membrane integrity.

Calculates pore size distribution for a comprehensive understanding of the membrane's structure.

Standard compliant test methods (ASTM E1294. ASTM F316) are widely used and recognized.

Can be used to test a wide range of membrane types and pore sizes.

Non-destructive to the membrane under certain test conditions.

Product Features:

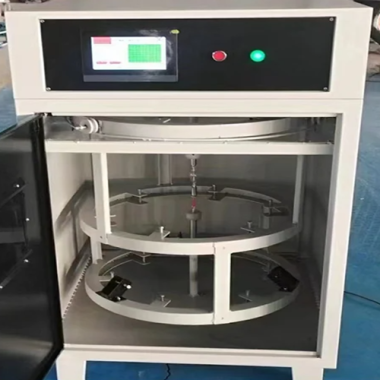

Test stand with a membrane holder or cell designed to securely clamp and seal flat membrane specimens, separating the upstream (gas) and downstream (flow measurement) sides.

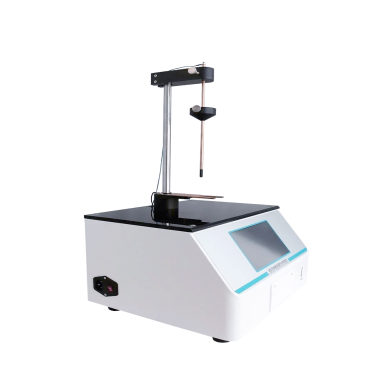

Pressure control system capable of precisely applying and gradually increasing the gas pressure to the upstream side of the wetted membrane.

Gas flow meter (or multiple flow meters for different ranges) to accurately measure the gas flow rate passing through the membrane.

Pressure transducer to accurately measure the applied gas pressure.

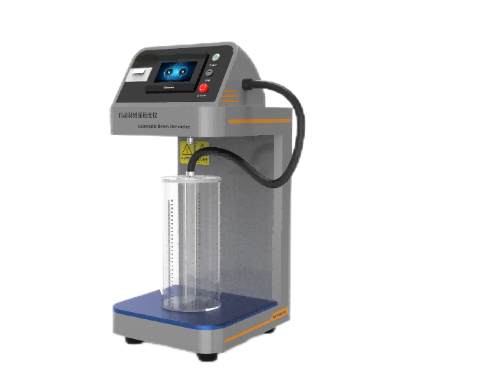

Reservoir or system for introducing and managing the wetting fluid used to saturate the membrane.

Automated control system for executing the entire test sequence (wetting, pressurization ramp, data acquisition, flow measurement).

Data acquisition and analysis software to record pressure and flow data, perform calculations based on physical models, and generate pore size distribution curves, bubble point, and mean flow pore size results.

Digital display showing real-time pressure, flow rate, and test status.

Temperature sensor to monitor the test temperature, as fluid properties are temperature-dependent.

Safety features for pressurized systems.

Send product request

Other supplier products

| SUGA SX75 7.5kW Super Xenon Weather Meter | SX75 accelerates the degradation of materials by exposing them to simulated outdoor and indoor environments such as sunlight,temperature,humidity... | |

| Helmet UV Pretreatment Box Tester / Helmet UV pretreatment box | Product Introduction Helmet ultraviolet pretreatment box is used for helmet ultraviolet irradiation pretreatment, according to the new national st... | |

| RIDER Method Single Fiber Friction Tester | Meet the standard: JIS L1015 (Chemical fiber binding test method), JIS L 1095 (General yarn test method)/friction coefficient Purpose: This inst... | |

| Automatic Down Filling Tester / Down and Feather Testing Machine | Introduction The loftiness index is one of the important indicators of feather and down quality. It is a concentrated manifestation of the interna... | |

| Qinsun Xenotest 220 | Standards ISO 105-B02: Lightfastness testing for colored textiles. AATCC TM16 (Option 3): Accelerated weathering for textiles under controlle... |

Same products

| Bottle Wall and Bottom Thickness Tester | Seller: Standard International Group (HK) Limited | The wall and bottom thickness tester for bottles is a measuring instrument widely used in the pha... | |

| Pinhole Tester / Pinhole Testing Equipment | Seller: Standard International Group (HK) Limited | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in ... | |

| Cork Puncture and Chip Detection Instrument | Seller: Standard International Group (HK) Limited | The rubber stopper puncture debris detector is a device specifically used to detect the number of... | |

| Aluminum Ointment Tube Toughness Tester | Seller: Standard International Group (HK) Limited | The ductility tester for aluminum tubes is a device specifically used to detect the ductility ind... | |

| Vacuum leak tester / Vacuum leak instrument | Seller: Standard International Group (HK) Limited | Vacuum Decay Leak Tester specializes in the detection of leaks in ampoules, vials, injection bott... |