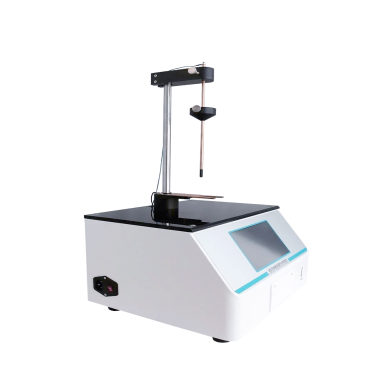

Vacuum leak tester / Vacuum leak instrument

Vacuum Decay Leak Tester specializes in the detection of leaks in ampoules, vials, injection bottles, freeze-dried powder injection bottles, and pre-filled packages.

Test Standards:

This test instrument conforms to many national and international standards: USP1207. YY/T 0681.18-2020

Product Features:

Micro leaks are detected in packages. The samples can be reused to reduce costs effectively.

Environmental temperature and humidity monitoring device.

Detect small and large leaks and the system determines qualified or unqualified automatically.

Test method: Vacuum Decay Method

Test time is less than 30s.

Test chambers can be selected for different samples and can be easily replaced.

Print test results automatically, ensuring accuracy and objectivity.

Statistical analysis is automatically performed on the test results, including yield statistics and sample normal distribution chart.

Equipped with micro printer, USB.

Automatically save, query, and export reports to Excel and PDF formats.

Meet GMP requirement, user-graded permission setting, historical record audit tracking function.

PC software is optional.

Technical Specifications:

Application: Ampoule, Vial, Injection Bottle, and Pre-filled Package

Test Method: Vacuum Decay Method (Non-destructive Test)

Test Chamber: Customization per Samples

Vacuum Degree: 0 ~ -100 kPa

Testing System: Dual-sensor Technology

Detection Sensitivity: 1 ~ 2 μm in diameter

Test Time: Less than 30s

Vacuum Source: Vacuum Pump

Environment Temperature: 15°C ~ 30°C

Relative Humidity: Up to 80%RH. No condensation.

Power Supply: AC 100-240V 50/60Hz (can be changed to local requirement)

Instrument Dimension: 320 mm (W) x 520 mm (D) x 350 mm (H)

Net Weight: 20 kg

Configurations:

Instrument, Vacuum Pump, Micro Printer, Test Chamber, Professional Software, 485 Communication Cable, Calibrated Flow Meter, Customized Test chamber, Positive Specimen, Negative Specimen

Send product request

Other supplier products

| Print rub tester / Ink Rub Tester | Product Introduction: Print friction testing machine is suitable for print, ink, photosensitive layer of PS plate, gloss oil and related products ... | |

| Geosynthetic acid and alkali aging tester丨Geotextile Test Machine | Scope of application: Test method for acid-resistant lye properties of various geosynthetic materials; The machine has stirring function, the solu... | |

| Pinhole Tester / Pinhole Testing Equipment | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in aluminum foil materials. The following is a detail... | |

| Shoelace anti-siphon tester 丨Shoelace Tester | Product Introduction Shoelace anti-siphon tester is suitable for all kinds of waterproof leather, leather, mesh, waterproof shoelace, ribbon water... | |

| Shoe Heel Impact Fatigue Tester / Shoe Heel Fatigue Tester | Meet the standard BS-5131 SATRA TM21. etc Main uses Heel impact fatigue testing machine is mainly used to test the continuous impact tolerance ... |

Same products

| Bottle Wall and Bottom Thickness Tester | Seller: Standard International Group (HK) Limited | The wall and bottom thickness tester for bottles is a measuring instrument widely used in the pha... | |

| Pinhole Tester / Pinhole Testing Equipment | Seller: Standard International Group (HK) Limited | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in ... | |

| Cork Puncture and Chip Detection Instrument | Seller: Standard International Group (HK) Limited | The rubber stopper puncture debris detector is a device specifically used to detect the number of... | |

| Aluminum Ointment Tube Toughness Tester | Seller: Standard International Group (HK) Limited | The ductility tester for aluminum tubes is a device specifically used to detect the ductility ind... | |

| Vacuum leak tester / Vacuum leak instrument | Seller: Standard International Group (HK) Limited | Vacuum Decay Leak Tester specializes in the detection of leaks in ampoules, vials, injection bott... |