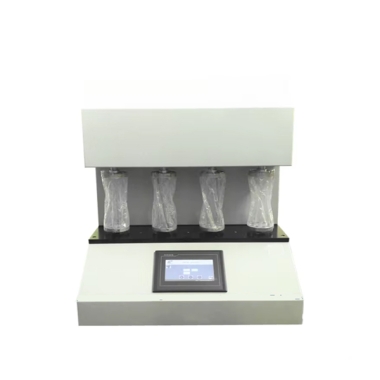

Catheter Hydraulic Leakage Tester

Compliance Standards

GB/T 15812.1. etc.

Main Uses

The catheter hydrostatic pressure resistance and leakage tester is a device specifically designed to evaluate the sealing performance of catheters in a hydraulic environment. Its main uses include:

Ensuring Catheter Safety: Through testing, it ensures that catheters have good sealing performance under various usage conditions, preventing liquid leakage and thus safeguarding the safety of patients.

Improving Product Quality: It provides data support for medical device manufacturers, helping them to improve the design and manufacturing processes of catheters, and enhancing the quality and reliability of products.

Promoting Technological Advancement: The application of the tester promotes technological progress and development in the medical field, and provides a powerful testing tool for the research and development of new - type catheters.

Technical Parameters

Test Flow: Usually 30L/min, with an error not exceeding ±5%. This parameter ensures that the tester can provide a stable and accurate flow during the test.

Pressure Range: Generally 0 - 500KPa, with a resolution of 0.01KPa and an error not exceeding ±1%. This parameter range covers the pressure range that most catheters can withstand in actual use, ensuring the comprehensiveness of the test.

Measurement System Holding Time: Usually 1 minute and can be set. This parameter ensures that the tester can maintain a stable measurement environment during the test, improving the accuracy of the test.

Test Duration: Generally 1 second - 99.9 minutes, with an error not exceeding ±1 second. This parameter range allows users to flexibly set the test time according to actual needs, ensuring the adequacy and effectiveness of the test.

Applicable Catheter Types: It is applicable to a variety of medical device products such as infusion sets, blood transfusion sets, infusion needles, filters, pipelines, catheters, and quick - connect fittings. This wide - ranging applicability enables the tester to meet the testing needs of different medical device products.

Send product request

Other supplier products

| Washing Fastness testing machine | Washing Fastness Tester | G228B washing fastness tester is used for washing, dry-clean color fastness testing. Electric touch switch, LCD menu display, without mechanical co... | |

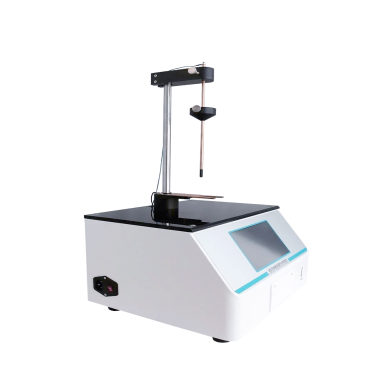

| Catheter Power Injection Flow and Pressure Tester YY 0285.1 | Main Uses The catheter flow and pressure tester for power injection is an important medical device, mainly used to detect key parameters such as f... | |

| Flex Durability Tester ASTM | The rubbing resistance tester is a device specifically used to detect the rubbing resistance performance of materials. The following is a detailed ... | |

| Rubber Resilience Tester | Rubber Tester | Standard Complies withISO 4662:1986(international),JIS K6255(Japan), andGB/T 1681(China) standards for standardized resilience testing of vulcaniz... | |

| Catheter Residual Vacuum Tester YY/T 0339 | Compliance Standards YY/T 0339 - 2019 Suction Catheters for the Respiratory Tract, etc. Main Uses The catheter residual vacuum tester is mainly ... |

Same products

| Bottle Wall and Bottom Thickness Tester | Seller: Standard International Group (HK) Limited | The wall and bottom thickness tester for bottles is a measuring instrument widely used in the pha... | |

| Pinhole Tester / Pinhole Testing Equipment | Seller: Standard International Group (HK) Limited | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in ... | |

| Cork Puncture and Chip Detection Instrument | Seller: Standard International Group (HK) Limited | The rubber stopper puncture debris detector is a device specifically used to detect the number of... | |

| Aluminum Ointment Tube Toughness Tester | Seller: Standard International Group (HK) Limited | The ductility tester for aluminum tubes is a device specifically used to detect the ductility ind... | |

| Vacuum leak tester / Vacuum leak instrument | Seller: Standard International Group (HK) Limited | Vacuum Decay Leak Tester specializes in the detection of leaks in ampoules, vials, injection bott... |