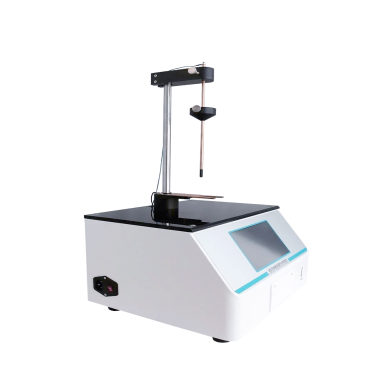

Sauce Packet Pressure Testing Instrument

The pressure resistance tester for sauce packets is a device specifically designed to test the pressure - resistance performance of soft packaging materials such as sauce packets. The following is a detailed description of its main uses, compliance standards, and technical parameters:

Standards

The design and manufacture of the pressure resistance tester for sauce packets usually comply with a series of national and international standards to ensure the accuracy and reliability of test results. These standards may include, but are not limited to:

- Relevant packaging pressure - resistance strength test standards such as GB/T 10004. These standards specify the test methods for the pressure - resistance performance of packaging materials, specimen preparation, test conditions, etc.

- Specific food packaging safety standards, such as the safety standards for food - contact materials, to ensure that the products will not be contaminated or endangered during the testing process.

Main Uses

The main purpose of the pressure resistance tester for sauce packets is to evaluate the ability of soft packaging materials like sauce packets to withstand pressure during transportation, storage, and use.

By simulating the pressure conditions in the actual environment, the tester can detect whether the sauce packets will burst or leak under pressure, thus ensuring the safety and integrity of the products.

This is of great significance to the food industry, as a damaged sauce packet may lead to product contamination, spoilage, or waste, which in turn affects consumers' purchase intention and brand reputation.

Technical Parameters

The technical parameters of the pressure resistance tester for sauce packets may vary depending on the model and brand, but the following are some common parameter ranges and functional features:

- Test Pressure Range: The test pressure is usually adjustable within a certain range, such as from 0.1 MPa to 0.7 MPa (equivalent to a pressure of 1 - 50kg) to adapt to different sauce packets and test requirements.

- Test Time: The test time can be set according to actual needs, usually with a wide adjustment range, such as from 1 second to hundreds of thousands of seconds.

- Specimen Size: The tester is generally suitable for specimens of certain sizes, and the specific size range may vary depending on the device model. In actual testing, appropriate cutting or adjustment is required according to the size and shape of the sauce packets.

- Control System: Modern pressure resistance testers for sauce packets usually adopt advanced control systems, such as micro - computer control or PLC control, to achieve automated operation and precise control. These systems usually have a user - friendly interface and easy - to - operate functions, such as pressure adjustment and data recording.

- Data Recording and Analysis: The tester is usually equipped with a data recording system and analysis software, which can automatically record data such as pressure changes and specimen deformation during the test and generate detailed test reports. This data can be used for subsequent product quality analysis and improvement.

- Safety Devices: To ensure the safety of operators, the pressure resistance tester for sauce packets is usually equipped with various safety protection devices, such as emergency stop buttons and overload protection. These devices can quickly cut off the power supply or stop the test in case of an emergency to prevent equipment damage or personal injury.

Send product request

Other supplier products

| Shoelace Abrasion Tester / SATRA TM93 | Application: This shoelace abrasion tester is used for shoelace against standard eyelet abrasion testing, or eyelet against standard shoelace abra... | |

| SUGA S80 Carbon Arc Weathering Tester | Applicable Standards The SUGA S80 adheres to globally recognized standards, including: ISO, AATCC, ASTM(e.g., ASTM G152. ASTM D822 for coatings... | |

| Plastic Pipe Hydrostatic Pressure Burst Tester / Pipe Hydrostatic Pressure And Burst Tester | Standard ISO 1167: For thermoplastics pipe systems under constant internal pressure. ASTM D 1598: Standard test method for time-to-failure of pla... | |

| AT1000 Abrasion Resistance Tester | Device description The at1000 wear tester has been used around the world since 1970 and is ideal for comparison and quality control of platelet-sh... | |

| Humidifying Bottle Performance Tester | Compliance Standards YY/T 1610 - 2018 Main Uses The humidifier bottle performance tester is mainly used to detect various properties of humidifi... |

Same products

| Bottle Wall and Bottom Thickness Tester | Seller: Standard International Group (HK) Limited | The wall and bottom thickness tester for bottles is a measuring instrument widely used in the pha... | |

| Pinhole Tester / Pinhole Testing Equipment | Seller: Standard International Group (HK) Limited | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in ... | |

| Cork Puncture and Chip Detection Instrument | Seller: Standard International Group (HK) Limited | The rubber stopper puncture debris detector is a device specifically used to detect the number of... | |

| Aluminum Ointment Tube Toughness Tester | Seller: Standard International Group (HK) Limited | The ductility tester for aluminum tubes is a device specifically used to detect the ductility ind... | |

| Vacuum leak tester / Vacuum leak instrument | Seller: Standard International Group (HK) Limited | Vacuum Decay Leak Tester specializes in the detection of leaks in ampoules, vials, injection bott... |