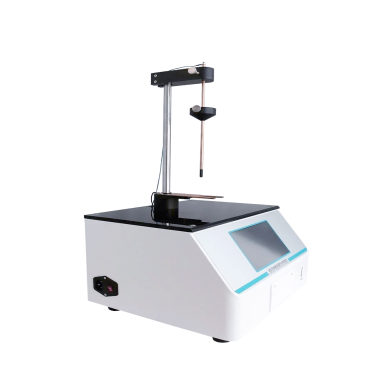

AT1000 Abrasion Resistance Tester

Device description

The at1000 wear tester has been used around the world since 1970 and is ideal for comparison and quality control of platelet-shaped fillers and pigments. When these fillers and pigments are used, the unit provides information on the wear properties of paper machine screens, cutting and stamping tools, as well as roller conveyors and blades. The at 1000 wear testing machine has been in production since 1970 and its functional principle has remained the same.

However, the device has been improved every once in a while in terms of handling, test accuracy and long-term accuracy. All the experience gathered since its launch has been integrated into the design of the original Einlehner AT 1000. the latest model from STD. The device is equipped with an integrated touch screen for intuitive and easy operation. The rotary mill rotates at a standard speed of 1450 RPM or 1800 RPM independent of the main frequency (50-60 Hz)。

In addition, the new electronic system can be used to select any other rotation value. The preset and actual revolutions (up to 999.990 revolutions) are displayed on the touch screen, and the speed of the grinding mixer can be controlled. The bottom of the mixing rod is narrower because it is submerged in the suspension. This keeps the top deflector free from contamination.

Applicable Standards

Zellcheming-Merkblatt V / 27.5/75

Product Features

High-speed rotary mill mechanism designed to create a turbulent suspension of the test material and abrade a test screen or wear plate.

Mixing rod with a narrower bottom section to prevent contamination of the upper components.

Integrated touch screen interface for intuitive and easy operation.

Display of preset and actual revolutions of the rotary mill, with a counting range up to 999.990 revolutions.

Capability to control the speed of the grinding mixer (rotary mill).

Standard rotary speeds of 1450 RPM or 1800 RPM, with the ability to select any other rotation value electronically.

Made with quality materials and manufacturing processes.

Special tools for simple PVC ring installations (PVC rings are likely components used in the test setup).

Includes 11 measuring cups (likely used for preparing or handling test suspensions).

Includes a starter kit with 500 screens, 200 PVC rings, and 25 stainless steel wear plates (consumable test materials).

Quality materials and manufacturing.

Special technology since 1970.

The touch screen operation is intuitive and convenient.

Special tools for simple PVC ring installations.

An 11 measuring cup.

1 starter kit, 500 screens, 200 PVC rings and 25 stainless steel wear plates.

Technical Parameters

| Specifications | •Top quality in material and manufacture

• A system that has been mature for a long time |

|

| mass and weight | Netto | Brutto |

| B × T × H [mm] | 250 × 250 × 512 | 400 × 400 × 600 |

| Weight [kg] | 29 | 45 |

| Special accessories | • Not included with the device but can be reordered:Testpackage AT 1000.consisting of 500 standard test sieves, 200 PVC covers and 25 wear plates. This material is sufficient for 500 wear tests.

• Special holder for discs with PVC rings for abrasion tests in kaolin suspensions • Standard pigment for reference |

|

| Electricity: | 220 – 240 V, 1-phase, 50/60 Hz or 220 – 240 V, 1-phas, 50/60 Hz (other values on customer req | |

Send product request

Other supplier products

| Geosynthetics thickness tester丨Thickness Gauge | Scope of application: Used to determine the thickness of various geosynthetic materials under specified pressure and time. The sample is placed on... | |

| AT1000 Abrasion Resistance Tester | Device description The at1000 wear tester has been used around the world since 1970 and is ideal for comparison and quality control of platelet-sh... | |

| Universal Friction Wear Tester - High Precision Friction & Wear Testing Machine | Theuniversal wear and abrasion resistance testeris used to test wear and abrasion resistance of fabrics for apparel, shoes, upholstery, automotive,... | |

| Ball Rebound Tester / STANDARD | Standard: DIN EN ISO 8307 ASTM D 3574 Main application scope and functions: This machine is designed and manufactured according to GB/T6670-97.... | |

| Heel Fatigue Tester ISO 19956 | Heel Fatigue Tester is used to determine the resistance of medium and high heels of ladies’ shoes under repeated small impacts to the heel ti... |

Same products

| Bottle Wall and Bottom Thickness Tester | Seller: Standard International Group (HK) Limited | The wall and bottom thickness tester for bottles is a measuring instrument widely used in the pha... | |

| Pinhole Tester / Pinhole Testing Equipment | Seller: Standard International Group (HK) Limited | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in ... | |

| Cork Puncture and Chip Detection Instrument | Seller: Standard International Group (HK) Limited | The rubber stopper puncture debris detector is a device specifically used to detect the number of... | |

| Aluminum Ointment Tube Toughness Tester | Seller: Standard International Group (HK) Limited | The ductility tester for aluminum tubes is a device specifically used to detect the ductility ind... | |

| Vacuum leak tester / Vacuum leak instrument | Seller: Standard International Group (HK) Limited | Vacuum Decay Leak Tester specializes in the detection of leaks in ampoules, vials, injection bott... |