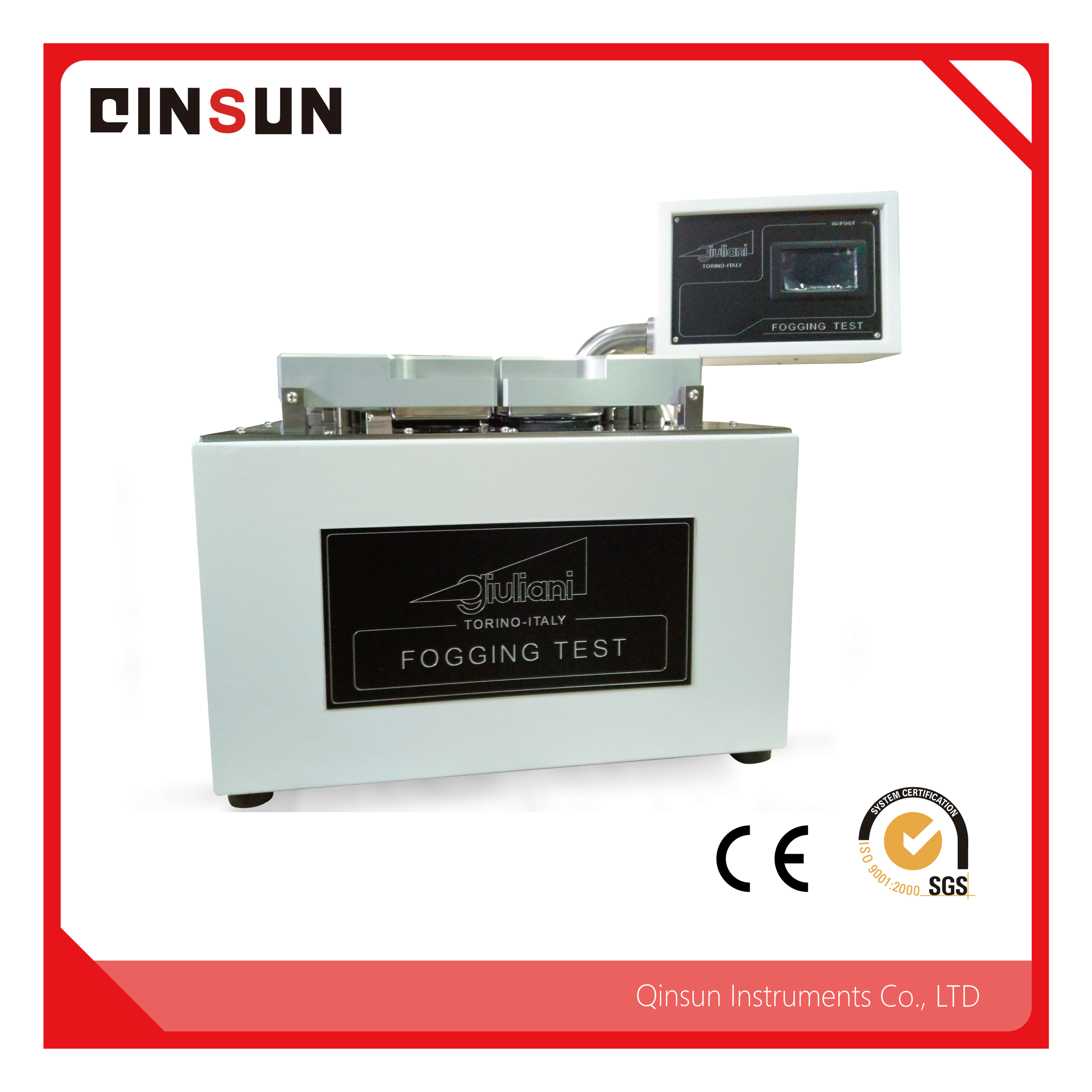

vehicle windscreen fogging tester with SAE J1756

Fogging tester is professionally designed for the fogging characteristics evaluation of volatile constituents of decorating materials used in cars and aircrafts, e.g. plastic articles, polyurethane, textiles, leather, adhesives, nonwovens and thermal forming elastomers at high temperature conditions. Fogging tester also could be used for the fogging phenomenon test of high intensity discharge (HID) headlamps of cars.

Standards

DIN 75201 Determination of the fogging characteristics of trim materials in the interior of automobiles

ISO 6452 Rubber or plastics coated fabrics-determination of fogging characteristics of trim materials

in the interior of automobiles

SAE J1756 Test procedure to determine the fogging characteristics of interior automotive materials

QB/T 2728 Leather-physical and mechanical test-determination of fogging characteristics.

BS EN 14288 Leather - Physical and mechanical tests - Determination of fogging characteristics

PV 3920 Determination of fog value (F) of non-metallic interior materials

PV 3015 Non-metallic materials for interior trim-determination of condensable constituents.

ES-X83231 Standard test method-For fogging of interior materials

NES M0161 Interior materials fog test method

D45 1727 TRIM MATERIALS AND PARTS FOR INTERIOR AND PASSENGER COMPARTMENT PARTS - FOGGING - CONDENSATION

GM 9305P Determination of fogging characteristics of automotive interior trim materials

TSM 0503G Fogging test method for non-metallic materials

Features:

CONSTRUCTIVE CHARACTERISTICS:

· Internal carrying plane, in structural treated steel, anti-acid painted.

· External protection in sheet steel of proper thickness, anti-acid treated and painted with epoxy resin.

· six work places 18/8 Inox steel test room.

· 18/8 Inox steel lift able cooling system.

· Rapid clutch Agitation System.

· Armored resistances.

· Security thermostat.

· Cooling liquid and relief entry etching with rubber-carrier.

SECURITY NORMS:

· Safety Magnetic Switch.

· Digital thermos regulator and microprocessor.

· Electronic auto programmable timer

· START-STOP switches,

· Warning Lamps.

· End test buzzer hint signal

Technical Parameter:

Hot bath temperature range: room temperature ~ 150 ℃ (room temperature ~ 280 ℃ optional)

High-temperature tank temperature control accuracy: ± 0.1 ℃ (150 ℃)

Low bath temperature range: 0 ~ 100 ℃

Cold tank temperature control accuracy: ± 0.1 ℃

High temperature trough Dimensions: 670 mm (L) × 490 mm (B) × 540 mm (H)

Cryogenic tank Dimensions: 400 mm (L) × 220 mm (B) × 520 mm (H)

Temperature tank Weight: 32kg (not including the thermally conductive medium)

Cryogenic tank Weight: 15kg (not including the thermally conductive medium)

Power: AC 220V 50Hz

Weight: 50kg

Size: 500 * 650 * 600mm

Temperature stability: ± 0.1 ° C (200 ° C)

Heating power: 3KW

Cooling capacity: 500W

Data communication: multi-function remote sensor and USB port

Safety magnetic switch

Warning Light

Test completion tips

Other supplier products

|

|

Abrasion & wear testing machine with Rotary Platform Dual (Double) Head |

taber abrasion & wear testing machine is commonly referred to as the Taber Abraser (Abrader) or Rotary Platform Dual (Double) Head Tester. Firs... |

|

|

Infectious Disease Portable Test Sampling Booth |

产品介绍:

为了更好地保障采样人员的安全,提供舒适的工作环境,我公司设计了可拆卸的核酸采样隔离箱,可以为检测人员提供安全的采样空间。

传染病便携式检测采样亭在核酸采样期间为检测人员提供正压和定向气流保护。负压可将气溶胶保持在采样亭内,并可选择单通道采样亭。通过使用气流来捕获和排... |

|

|

Medical face masks Automatic Filtering Performance Tester |

The tester is used for performance testing of filter elements, disposable masks, filter media, etc. for respiratory protection products. It's suita... |

|

|

Medical Face Masks filter material Particulate filtration efficiency tester |

Medical Face Masks filter material Particulate filtration efficiency tester

is used for performance testing of filter elements, disposable masks, ... |

|

|

45 Degree Flammability Test instruments |

Testing Standards:ASTM D1230, FTMS 191-5908, CFR 16 Part 1610, CALIF TB 117, NFPA 702, GB/T 14644Applications:45 degree flammability tester is desi... |

All supplier products

Same products