Guidewire Pushing Force Tester

Standards

YYT0807 - 2010 YY/T0663.2 - 2016

ASTMF2394 - 2007

Main Uses

The guidewire pushing force tester is a precision testing tool in the medical device industry, mainly used to test the mechanical properties of guidewires during the pushing process. This equipment plays a crucial role in the research, development, production, and quality - control processes of medical devices.

Its specific uses include: Testing in the R & D Stage: In the R & D stage of medical devices, the guidewire pushing force tester helps R & D personnel conduct comprehensive tests on the performance of new guidewires. By simulating pushing operations under different conditions, testers can obtain data on the mechanical properties of guidewires in various scenarios, and thus evaluate whether they meet the design requirements. This data provides valuable references for R & D personnel, enabling them to optimize the structure and performance of guidewires, and improve the overall quality of medical devices.

Quality Control in the Production Stage: During the production stage, the application of the guidewire pushing force tester ensures that each batch of guidewires meets the quality requirements. By regularly testing guidewires in the production process, manufacturers can promptly identify and resolve potential quality issues, ensuring product consistency and stability.

Optimization of Process Parameters: The guidewire pushing force tester can also be used to optimize process parameters during production, aiming to increase production efficiency and reduce costs.

Competitive Product Analysis and Market Strategy Formulation: Through strict testing of finished guidewires, manufacturers can ensure that products meet the predetermined performance standards. Meanwhile, this equipment can also be used to analyze and compare competing products on the market, helping manufacturers understand their own advantages and disadvantages, and thus formulate more targeted market strategies.

Comprehensive Testing Tasks: The guidewire pushing force tester can also be integrated with other medical equipment to perform more complex testing tasks. For example, by connecting it with a blood vessel simulator, testers can simulate the pushing process of guidewires in real blood vessels, and thus evaluate their performance more accurately. This comprehensive testing method contributes to improving the precision and reliability of medical device research and production.

Technical Parameters

Force - measuring Range: Depending on the specific model and application, the force - measuring range may vary. The force - measuring range of some testers can reach dozens of newtons.

Force - measuring Accuracy: Force - measuring accuracy is one of the important indicators for evaluating the performance of the tester. High - precision testers can provide more accurate test results, helping R & D personnel gain a more precise understanding of the performance characteristics of guidewires. The force - measuring accuracy of some testers can reach 0.1N or higher.

Testing Speed: The testing speed refers to the rate at which the tester applies force during the test. Different testing speeds may have different impacts on the performance of guidewires. Therefore, the tester usually has an adjustable testing - speed range to meet different testing needs. The testing - speed range of some testers may be between 0 - 500mm/min.

Equipment Composition: The guidewire pushing force tester typically consists of a testing main unit, an angle sensor, a torque sensing system, a force sensor, a roller clamping device, etc. These components work together to complete the pushing - force testing task of guidewires.

Send product request

Other supplier products

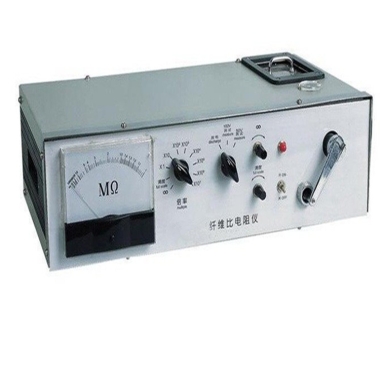

| Fiber Blend Ratio Tester | Product Introduction: It is used to measure the resistance value with a certain density under a certain geometry, and then converts it into the sp... | |

| Syringe Sealing Negative Pressure Tester | Meet the standard YY0053-2008. GB 15810-2019 single-use sterile syringe, ISO7886-1:2017 single-use sterile syringe, ISO7886-1. ISO8537-2016. YY04... | |

| Sweating Thermal Manikin | Standards compliant ISO 15831:2004(E) Clothing-Physiological effects -Measurement of ASTM F 1291-04Standard Test Method for Measuring the Thermal... | |

| Goggles Puncture Resistance Testing Machine | Applicable standards: GB 811-2010 ECE R22.05 EN1077 Purpose It is to make a certain weight of sharp objects fall from the height specified i... | |

| Battery Powder resistivity meter | Standards YS/T 587.6-2006 GB/T 24525-2009 GBT 30835-2014 Product Advantages Unmatched Measurement Flexibility Dual-probe compatibility: Switc... |

Same products

| Plastic Smoke Density Tester F313 | Seller: Standard International Group (HK) Limited | The F313 Plastic Smoke Density Tester is a precision instrument designed to measure the specific ... | |

| Xenon Test Chamber | Seller: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | Seller: Qinsun Instruments Co., LTD | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | Seller: Qinsun Instruments Co., LTD | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... | |

| Furniture flammability tester | Seller: Qinsun Instruments Co., LTD | Product details Furniture flammability tester is mainly used to test the combustion performance ... |