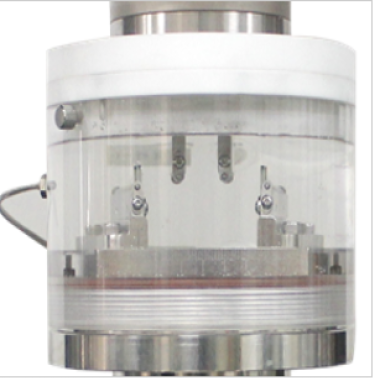

Digital display electronic ink viscosity meter

How it works:

The working principle of the digital display electronic ink viscosity meter is based on two tin (usually a metal roller and a rubber roller) rotating under a given pressure, speed and temperature conditions, by measuring the separation force of the ink film between the rollers to assess the viscosity of the ink. When the roller rotates, the ink film coated on it is subjected to shear force and separated, at this time the instrument records the force required to separate the ink film, thereby calculating the viscosity value of the ink.

Standard:

ISO 12644

Functional features:

Intelligent design: The use of advanced intelligent control system, can clearly and accurately display the instantaneous copper roll number, water tank temperature and other key parameters, and automatically adjust the test conditions that do not meet the requirements.

Multi-speed selection: Provide multi-speed copper roller spindle speed selection to adapt to different oil black types and test needs.

Thermostatic water tank: Equipped with a thermostatic water tank to ensure a constant temperature during the test process, improve the accuracy and repeatability of the test results.

Automatic measurement and calibration: The instrument has automatic measurement and calibration function, which can reduce the error caused by human operation and improve the test accuracy

Humanized design: The instrument design is humanized, easy to operate, easy to maintain and clean.

Application field:

Digital display electronic ink viscosity meter is widely used in printing, packaging, ink manufacturing and other industries to measure the viscosity value of various types of ink to ensure the quality and stability of printed matter. In addition, the instrument can also be used in ink research and development, quality control and product inspection.

Technical parameters:

The technical parameters of digital display electronic ink viscosity meter may vary from model to model and manufacturer, but usually include the following aspects:

Copper roller spindle speed: multi-speed adjustable, such as 400 RPM, 800 RPM, 1200 RPM, 1600 RPM or 2000 RPM, to adapt to different test needs.

Total electrical power: Usually between 1500 watts and 1600 watts, depending on the configuration and manufacturer of the instrument.

Pump flow rate: for the circulating water of the thermostatic water tank, the flow rate is generally greater than or equal to 10 liters/min to ensure the stability of the test environment.

Thermostatic water tank capacity: generally 6 to 8 liters, used to maintain a constant temperature during the test.

Display accuracy: usually 0.1 ink viscosity unit, to ensure the accuracy of measurement results,

Test accuracy: under the same test conditions, the retest error is generally controlled within +0.3 to +0.5 ink viscosity units.

Spindle level error: After the table is leveled, the spindle copper roller level error is usually controlled within 0.03 mm.

Thermostatic water tank temperature adjustment error: the temperature adjustment error of a single thermostatic water tank is generally less than or equal to 0.5 °C, and the temperature adjustment error of a dual-purpose thermostatic water tank may be smaller, such as less than or equal to 0.19°C

Send product request

Other supplier products

| UV Condensation Aging Test Chamber | Standard ASTM G154.ISO 4892-3.JIS K 7350. andSAE J2020for UV exposure testing. IEC 60068-2-78for condensation and humidity resistance evaluations... | |

| Bio-absorbable Internal Fixation Plates and Screws Test device | Standard YY/T 0509-2009 (China): Specifies mechanical testing protocols for orthopedic plates/screws made of hydrolyzable polymers, including axia... | |

| Temperature and Low Air Pressure Test Chamber | Features and Benefits 1.The test chamber combines a wide temperature and humidity range, low pressure range, can complete a variety of complex low... | |

| Cylindrical Battery In-Situ Volume Swelling Testing System | Standard UL 1642: Standard for Lithium Batteries IEC 62660-2: Secondary Lithium-Ion Cells – Part 2: Reliability and Abuse Testing ASTM E... | |

| Flooring Radiant Panel Test Apparatus | Standards ISO 9239-1: Flooring fire reaction test - Part 1: Combustion performance of flooring materials tested by radiantheat ASTM E 648: Crit... |

Same products

| Xenon Test Chamber | Seller: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | Seller: Qinsun Instruments Co., LTD | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | Seller: Qinsun Instruments Co., LTD | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... | |

| Furniture flammability tester | Seller: Qinsun Instruments Co., LTD | Product details Furniture flammability tester is mainly used to test the combustion performance ... | |

| Flame retardant testing machine | Seller: Qinsun Instruments Co., LTD | Feature highlights: Flame Retardant Tester is designed for testing plastic runway surface layers... |