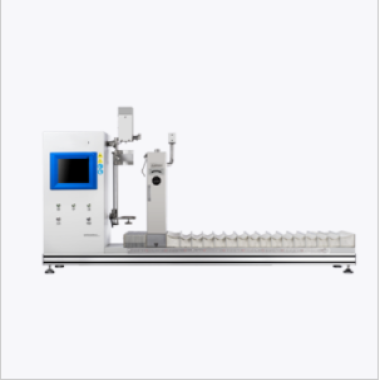

Spray Aerosol Ignition Distance Test device

Product Description

Conforms to UN Recommendations on the Transportation of Dangerous Goods - Manual of Tests and Criteria 31.4 Ignition Distance Test for Spray Aerosols and GB/T 21630-2008 Test Method for Ignition Distance for Dangerous Goods Spray Aerosols.

Standards

GB/T 21630-2008

GAT536

NY/T 1860

Product Features

1. It adopts an embedded processor and the Windows CE operating system.

2. With an 8 - inch liquid - crystal touch screen, it can display the test status in real - time.

3. It integrates two working modes: the "standard mode" and the "custom mode".

4. The aerosol sprays automatically, and the aerosol can clamping device can automatically make the can stand upright or turn it upside - down.

5. The nanosecond - level photosensitive sensor detection module automatically detects whether the spray is burning.

6. Driven by a hybrid stepping motor and equipped with an optical encoder, it enables precise positioning of the measurement position.

7. It uses a spark lighter as the ignition source, producing a blue - colored non - glowing flame with a height of 4 - 5 cm, and the flame height is adjustable.

8. The test process is fully automated, requiring no manual intervention. It supports functions such as parameter setting, data storage, and report viewing.

9. The dedicated fire - proof accordion cover can effectively prevent equipment contamination.

10. It is equipped with a temperature and humidity module to monitor the temperature and humidity of the test environment in real - time.

Technical parameters

|

Operating Environment |

(5~40)℃, <85%RH |

|

Ambient Temperature Measurement Range |

(-10~+60)℃ |

|

Ambient Temperature Measurement Accuracy |

±0.5℃ |

|

Ambient Humidity Measurement Range |

(5~95)%RH |

|

Ambient Humidity Measurement Accuracy |

±5.0%RH |

|

Flame Detection Response Time |

≤6ms |

|

Flame Detection Distance |

(15~90)cm |

|

Positioning Accuracy |

±1mm |

|

Minimum Pressing Duration |

5s |

|

Ignition Method |

Gas Igniter |

|

Aerosol Tank Positioning |

Aerosol canisters can be turned over automatically |

|

Compatible Spray Tank Dimensions |

Height (120~400)mm, Diameter (30~80)mm |

Send product request

Other supplier products

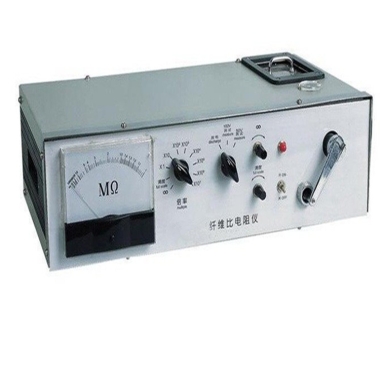

| Fiber Blend Ratio Tester | Product Introduction: It is used to measure the resistance value with a certain density under a certain geometry, and then converts it into the sp... | |

| Carpet tuft length measuring instrument | Standard BS 4223:1989 (British Standard): Specifies methods for determining the pile length of cut-pile carpets, ensuring consistency in quality... | |

| European Standard Washer | I. Product Overview TheEuropean Standard Washer(EN 14399-compliant) is a high-performance fastening component designed for industrial and automoti... | |

| Button Impact Resistance Testing Machine (for Button Impact Machine) | Standards: ASTM D5171: Test Method for Abrasion Resistance of Inks and Coatings (referenced for impact-related durability assessments). Applicati... | |

| Vacuum Ball - Disk Friction Tester | Standards ASTMD4172-94 ASTMD2266-91 SH/T0189-92 Main Purposes The vacuum ball - disk friction tester is a device specifically used for evaluat... |

Same products

| Plastic Smoke Density Tester F313 | Seller: Standard International Group (HK) Limited | The F313 Plastic Smoke Density Tester is a precision instrument designed to measure the specific ... | |

| Xenon Test Chamber | Seller: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | Seller: Qinsun Instruments Co., LTD | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | Seller: Qinsun Instruments Co., LTD | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... | |

| Furniture flammability tester | Seller: Qinsun Instruments Co., LTD | Product details Furniture flammability tester is mainly used to test the combustion performance ... |