Titanium carbide hard rods - available on demand

Compared with traditional high-speed steel, hard alloy titanium carbide round bars enable a 3 to 5 times increase in cutting speed, significantly reducing processing time in mass production. These materials exhibit a uniform microstructure with grain size controllable below 1 μm, ensuring consistent mechanical performance throughout the bar and minimizing tool failure due to material inhomogeneity. In the mold industry, cold stamping die inserts fabricated from this material demonstrate service lives 50 to 100 times longer than those made of conventional steel, substantially reducing replacement frequency and associated production costs. Owing to their excellent electrical conductivity, titanium carbide round bars are suitable for use as electrodes in electrical discharge machining (EDM), where they exhibit low electrode wear and high machining accuracy in the fabrication of precision molds. The material also exhibits superior fatigue resistance and is resistant to cracking under repeated impact loading, making it ideal for manufacturing components subject to high-frequency vibrations. In the nuclear energy sector, its exceptional radiation resistance renders it suitable for machining tools used in the internal components of nuclear reactors. The round bars are available in customizable lengths ranging from 100 mm to 1000 mm and can undergo secondary processing operations such as precision grinding and wire-cut EDM to produce complex-shaped components. Although the initial cost is higher than that of conventional cemented carbide, the overall cost per unit product is lower when accounting for extended service life and improved processing efficiency. In gear manufacturing, hobs made from this material ensure gear tooth surface accuracy of grade 6 or higher, meeting the stringent requirements of high-performance mechanical transmission systems.

Send product request

Other supplier products

| Chromium carbide powder with outstanding forming effect | Chromium carbide powder is a grayish-black powder with a melting point of approximately 1890℃ and a Mohs hardness of 8.5. It features excellent wea... | |

| Reduce the sintering temperature of titanium carbide powder by 200℃ | This powder has excellent electrical and thermal conductivity, with an electrical conductivity of 3×10⁴S/m and a thermal conductivity of 35W/... | |

| Coating raw material for wear resistance and corrosion resistance | The preparation methods of this powder mainly include the electric arc furnace method and the carbon thermal reduction method. Among them, the powd... | |

| Chromium carbide powder that facilitates green surface treatment and the development of new materials | Chromium carbide powder is often irregular grayish-black particles with a particle size of 10-40μm, a purity of ≥98%, and a free carbon conte... | |

| Fiber Optic Cutting Knife Round Rod | Titanium carbide cermet rods (TiC rods) belong to the group of steel-jointed cemented carbides, which are composites of steel as the bonding phas... |

Same products

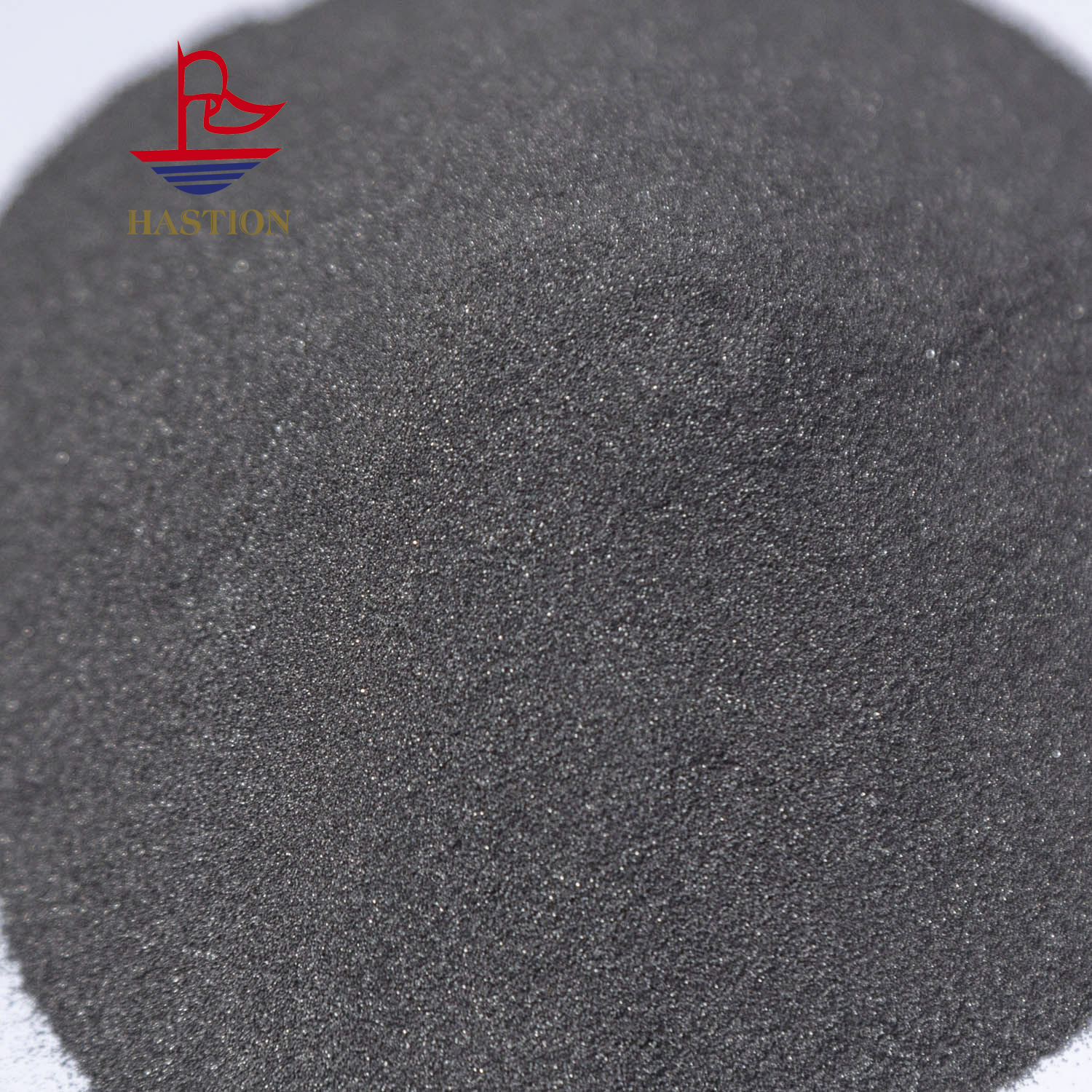

| 3D printing spherical titanium carbide powder | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This batch of titanium carbide powder (TiC) has a purity of over 99.5%, with a particle size cont... | |

| Titanium carbide hard alloy drive wheel - Specialized | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | The titanium carbide (TiC) guide wheel is fabricated via high-temperature powder metallurgy sinte... | |

| Industrial guide wheels, titanium carbide wear-resistant alloy | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This carbonized titanium (TiC) guide wheel is formed by high-temperature sintering of 99.5% pure ... | |

| Unfinished bar stock - heat treatable | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This high-purity titanium carbonitride (TiCN) round bar is fabricated via hot-pressing and sinter... | |

| Steel-based titanium carbide hard alloy round bar | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This carbonitride round bar (TiC) is formed by hot-pressing and sintering 99.5% high-purity carbo... |