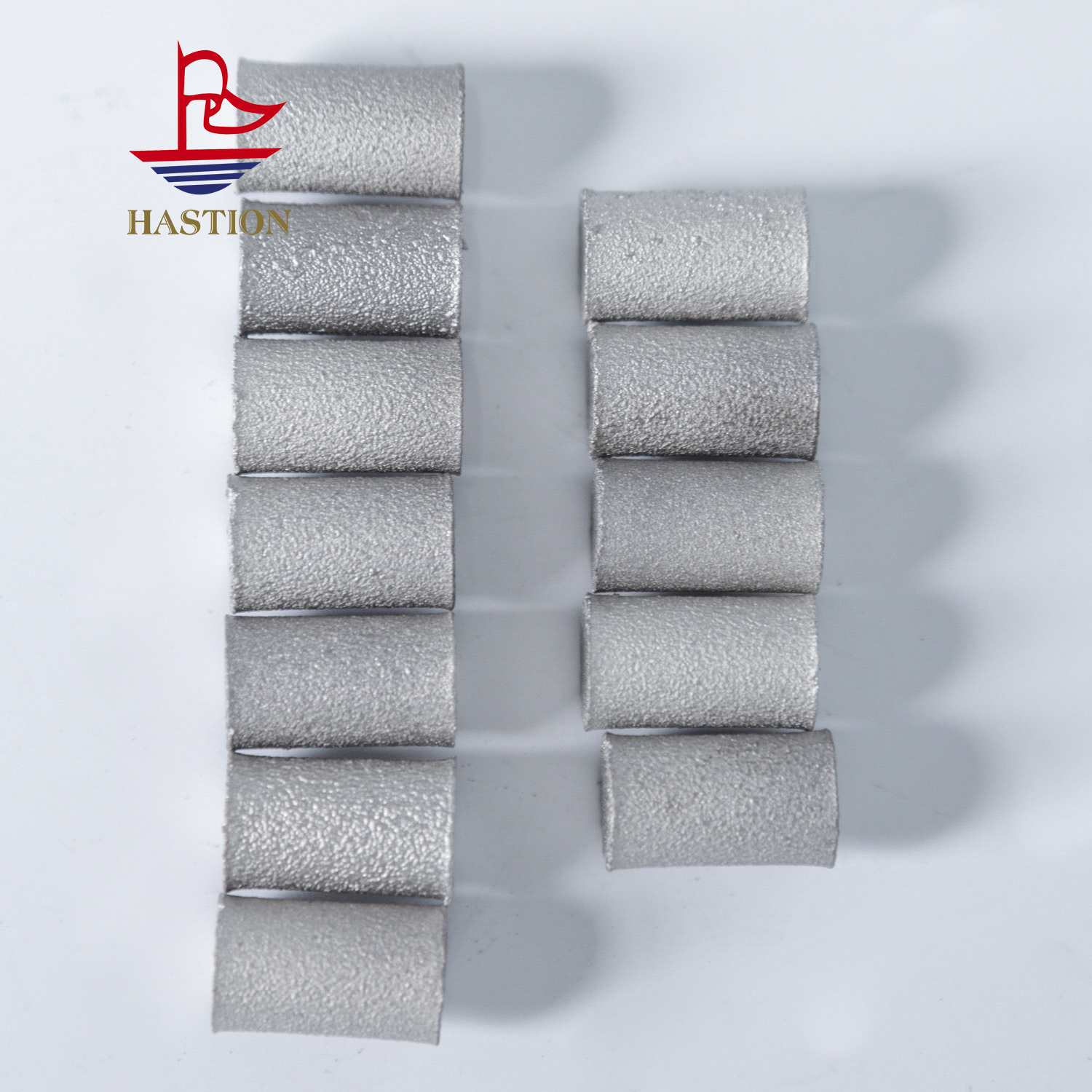

Customized grade chromium carbide powder

The main methods for preparing this powder include the electric arc furnace method and the carbothermal reduction method. Among them, the powder produced by the carbothermal reduction method has a finer particle size and a lower cost, making it suitable for large-scale application. When the oxygen content of the powder is less than 0.2%, it can reduce the pores and inclusions in the coating and improve the density of the coating. After spraying chromium carbide powder on the surface of the valve tappets of a car engine, the wear of the tappets can be reduced by 80%, and the major overhaul cycle of the engine can be prolonged. Chromium carbide powder is often irregular grayish-black particles with a particle size of 10-40μm, a purity of ≥98%, and a free carbon content of ≤0.5%. It features high hardness and excellent wear resistance, with a bulk density of 2.9-3.2g/cm³, and is suitable for thermal spraying and surfacing processes. It is widely used for surface strengthening of easily worn parts such as mine crusher liners and metallurgical roller tracks, effectively resisting material erosion and extending the service life of equipment. This chromium carbide powder is black in color, with a particle size of 5-25μm, a purity of over 99%, and extremely low impurity content. The particles have good dispersibility and are easy to mix with the metal matrix. After powder metallurgy sintering, highly wear-resistant parts can be produced. It is applicable to precision bearings, micro gears and other precision instrument components, which can reduce wear and improve the operational accuracy and stability of equipment.

Send product request

Other supplier products

| Customized titanium carbide powder | This powder has good electrical and thermal conductivity, electrical conductivity of 3 × 10⁴S/m, thermal conductivity of 35W/(m-K), can be ... | |

| Titanium carbide hard alloy guide wheel - Customized version | 这种硬质合金碳化钛导轮具有优异的抗热冲击性能。即使温度从室温骤升至300℃,再骤降至室温,也不会发生开裂,因此适用于间歇性生产环境。导轮尺寸范围广,直径从50mm到500mm,宽度从10mm到100mm,可适配不同类型的拉丝或轧制设备。在光纤和光缆生产中,它可以精确引导光纤,使光纤衰减率保持在... | |

| High-density titanium carbide rods - special for guide pins and guide sleeves | Titanium carbide round rods of cemented carbide are high-performance rods made by powder metallurgy process, with titanium carbide as the main hard... | |

| Wear-resistant titanium carbide rods - special for drilling equipment | Titanium carbide round rods made of hard alloy have excellent electrical conductivity and can be used to make electrodes for electrical discharge m... | |

| Free Sample Chromium Carbide Powder | Chromium carbide powder is gray-black in color, with high hardness, excellent abrasion resistance, high temperature and chemical corrosion resist... |

Same products

| 3D printing spherical titanium carbide powder | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This batch of titanium carbide powder (TiC) has a purity of over 99.5%, with a particle size cont... | |

| Titanium carbide hard alloy drive wheel - Specialized | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | The titanium carbide (TiC) guide wheel is fabricated via high-temperature powder metallurgy sinte... | |

| Industrial guide wheels, titanium carbide wear-resistant alloy | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This carbonized titanium (TiC) guide wheel is formed by high-temperature sintering of 99.5% pure ... | |

| Unfinished bar stock - heat treatable | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This high-purity titanium carbonitride (TiCN) round bar is fabricated via hot-pressing and sinter... | |

| Steel-based titanium carbide hard alloy round bar | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This carbonitride round bar (TiC) is formed by hot-pressing and sintering 99.5% high-purity carbo... |