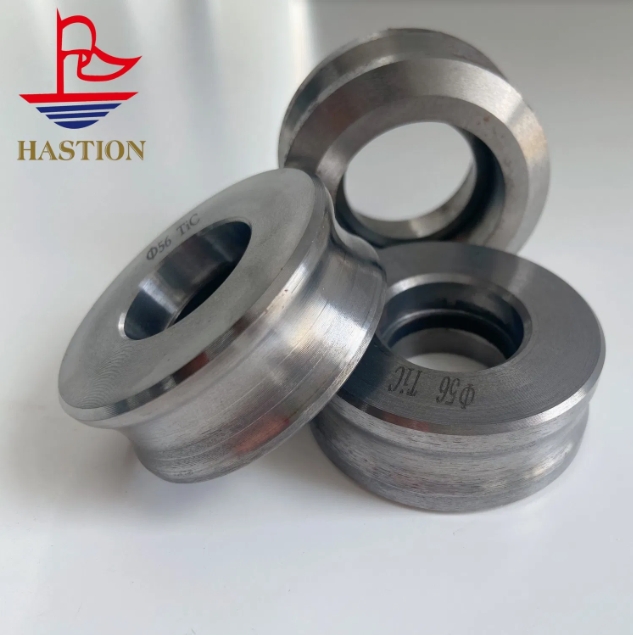

High wear-resistant titanium carbide guide wheel - alloy

The surface of the guide wheel can be specially treated according to specific requirements. For example, applying a diamond coating can enhance its wear resistance by 30%, making it suitable for processing high-hardness alloy wires. It is 30% lighter than steel guide wheels of comparable dimensions, thereby reducing the load on the drive motor and decreasing energy consumption by more than 15%. In precision tube manufacturing, the groove accuracy of the guide wheel achieves IT3 grade, ensuring the outer diameter tolerance of the tube is maintained within ±0.01 mm, meeting the stringent precision demands of industries such as medical technology and aerospace. Compared with ceramic guide wheels, this type exhibits superior toughness and is less prone to fracture from minor impacts, thus reducing replacement frequency. Its service life is 2 to 3 times longer than that of ceramic counterparts. In steel cord production, a single set of these guide wheels can process over 1,000 tons of cord, whereas ceramic guide wheels typically last only 300 to 500 tons. The favorable cost-performance ratio has facilitated widespread adoption in the tire industry, contributing to improved wear resistance and safety of tires.

Send product request

Other supplier products

| Ultra-high dimensional accuracy guaranteed titanium carbide round rods | The production process for these round bars is extremely rigorous, from the strict control of titanium carbide powder purity (purity ≥ 99.5%) ... | |

| High hardness ultra-fine grain carbide round rods for CNC cutting tools | Titanium carbide alloy round bar is a high-performance material made of titanium carbide (TiC) as a base, by adding metal or ceramic reinforcing ... | |

| Composite coated titanium carbide guide wheels | Carbide titanium carbide guide wheel is the key guiding parts in the production of wire and pipe, which is made of high purity titanium carbide and... | |

| Carbide guide rollers for wire and cable production | Lighter than Tungsten carbide roller by 55%, Lighter than tool steel than 20%, so the guide roller accelerates from standstill to 35,000 rpm, witho... | |

| Vacuum carbon thermal reduction for the preparation of titanium carbide powder | Titanium carbide powder has high sintering activity and can be densely sintered at temperatures between 1300 and 1500°C, which is 200 to 300&... |

Same products

| 99.5% high-purity chromium carbide powder | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | Chromium carbide powder has excellent wetting properties and is firmly bonded to metal substrates... | |

| Carbonitride powder for plastic modification | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | The particle morphology of this powder can be controlled, and it can be made into spherical, near... | |

| Titanium carbide hard alloy drive wheel accessory | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This guide wheel is customizable with various groove geometries—including V-shaped, U-shape... | |

| Industrial titanium carbide alloy drive wheels | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This guide wheel can be customized with various slot shapes according to the specifications of wi... | |

| Wear-resistant steel-bonded hard alloy round bar | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | Titanium carbide (TiC)-based cemented carbide round rods exhibit exceptional electrical conductiv... |