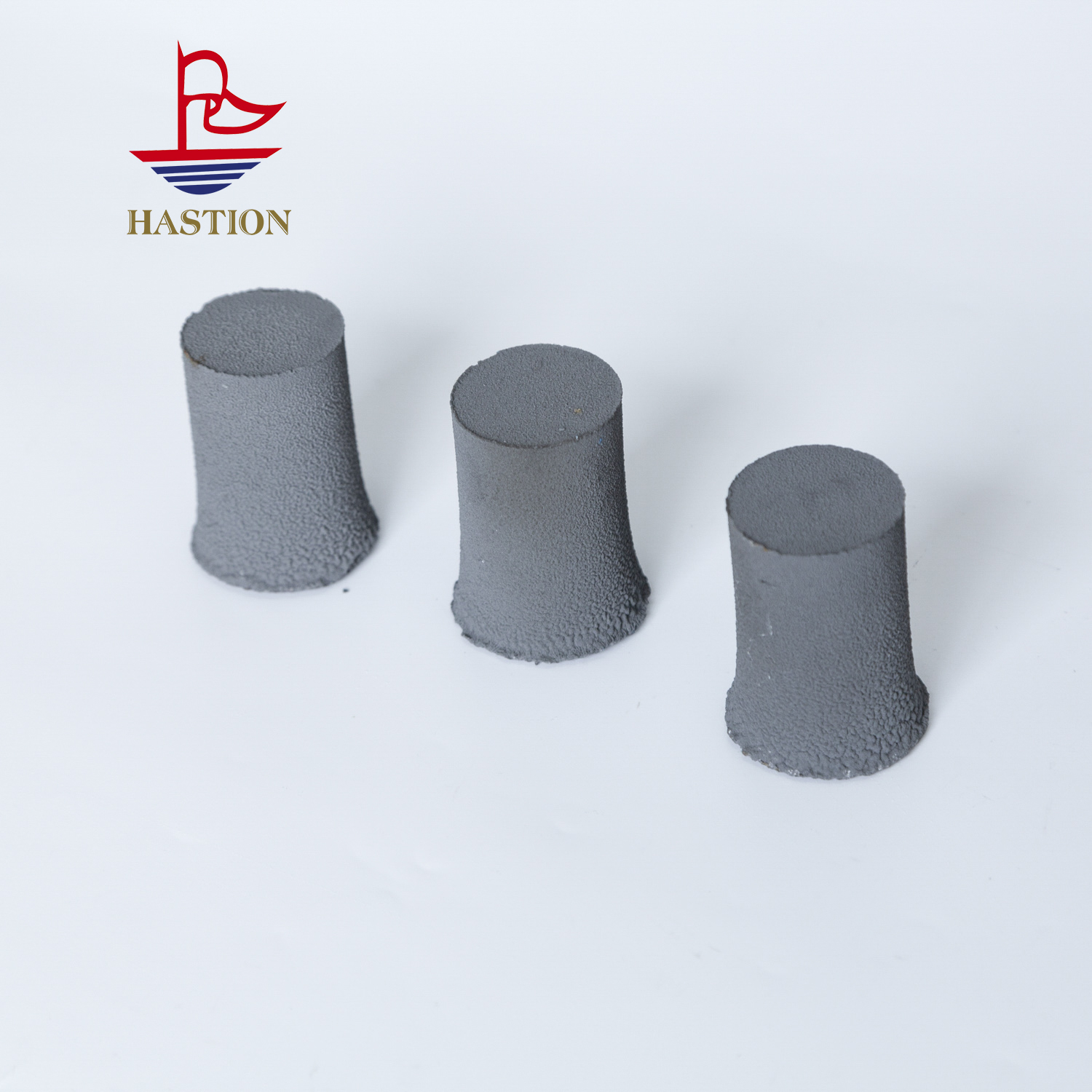

Titanium carbide hard rods - preferred for tool manufacturing

Titanium carbide cemented carbide round rods are high-performance components fabricated through a powder metallurgy process, with titanium carbide serving as the primary hard phase and cobalt or nickel as the binder phase. These rods exhibit exceptional hardness exceeding HRC85 and superior wear resistance compared to conventional steel. They maintain stable mechanical properties even in high-temperature environments above 500 °C. Characterized by extremely high dimensional accuracy, the rods can achieve diameter tolerances within ±0.01 mm and surface roughness as low as Ra 0.02 μm, making them ideal for the production of precision cutting tools and mold cores. Tools manufactured from this material demonstrate a service life 10 to 20 times longer than those made from high-speed steel when machining difficult-to-cut materials such as stainless steel and titanium alloys, thereby significantly enhancing production efficiency. With advancements in 3D printing technology, titanium carbide cemented carbide has also been processed into feedstock powder for additive manufacturing of precision components. The resulting printed parts achieve a density of up to 99.5% of theoretical density, with mechanical performance comparable to that of traditionally sintered counterparts. In the photovoltaic industry, these rods are employed as cutting tools for silicon wafers, ensuring thickness variation is controlled within ±1 μm and contributing to improved solar cell conversion efficiency. Owing to their outstanding performance across diverse applications, titanium carbide cemented carbide round rods have become an essential material in advanced manufacturing sectors.

Send product request

Other supplier products

| Dense and strong titanium carbide powder | Titanium carbide powder has excellent chemical stability, insoluble in water, hydrochloric acid, sulphuric acid and other common acids and alkalis,... | |

| High-performance chromium carbide powder | Chromium carbide powder is often irregular grayish-black particles with a particle size of 10-40μm, a purity of ≥98%, and a free carbon conte... | |

| High-strength titanium carbide rods - for ceramic processing | The manufacturing process of this round bar is highly stringent, encompassing rigorous control over the purity of titanium carbide powder (purity &... | |

| Fatigue life increased by 50% Titanium carbide round rods | titanium carbide round bars can be customised with different properties by adjusting the titanium carbide content (usually 70-90%) and binder rat... | |

| Titanium carbide rods - Mass production with favorable prices | The anti-adhesion performance of titanium carbide round rods made of hard alloy is outstanding. When processing sticky materials such as aluminum a... |

Same products

| 3D printing spherical titanium carbide powder | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This batch of titanium carbide powder (TiC) has a purity of over 99.5%, with a particle size cont... | |

| Titanium carbide hard alloy drive wheel - Specialized | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | The titanium carbide (TiC) guide wheel is fabricated via high-temperature powder metallurgy sinte... | |

| Industrial guide wheels, titanium carbide wear-resistant alloy | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This carbonized titanium (TiC) guide wheel is formed by high-temperature sintering of 99.5% pure ... | |

| Unfinished bar stock - heat treatable | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This high-purity titanium carbonitride (TiCN) round bar is fabricated via hot-pressing and sinter... | |

| Steel-based titanium carbide hard alloy round bar | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This carbonitride round bar (TiC) is formed by hot-pressing and sintering 99.5% high-purity carbo... |