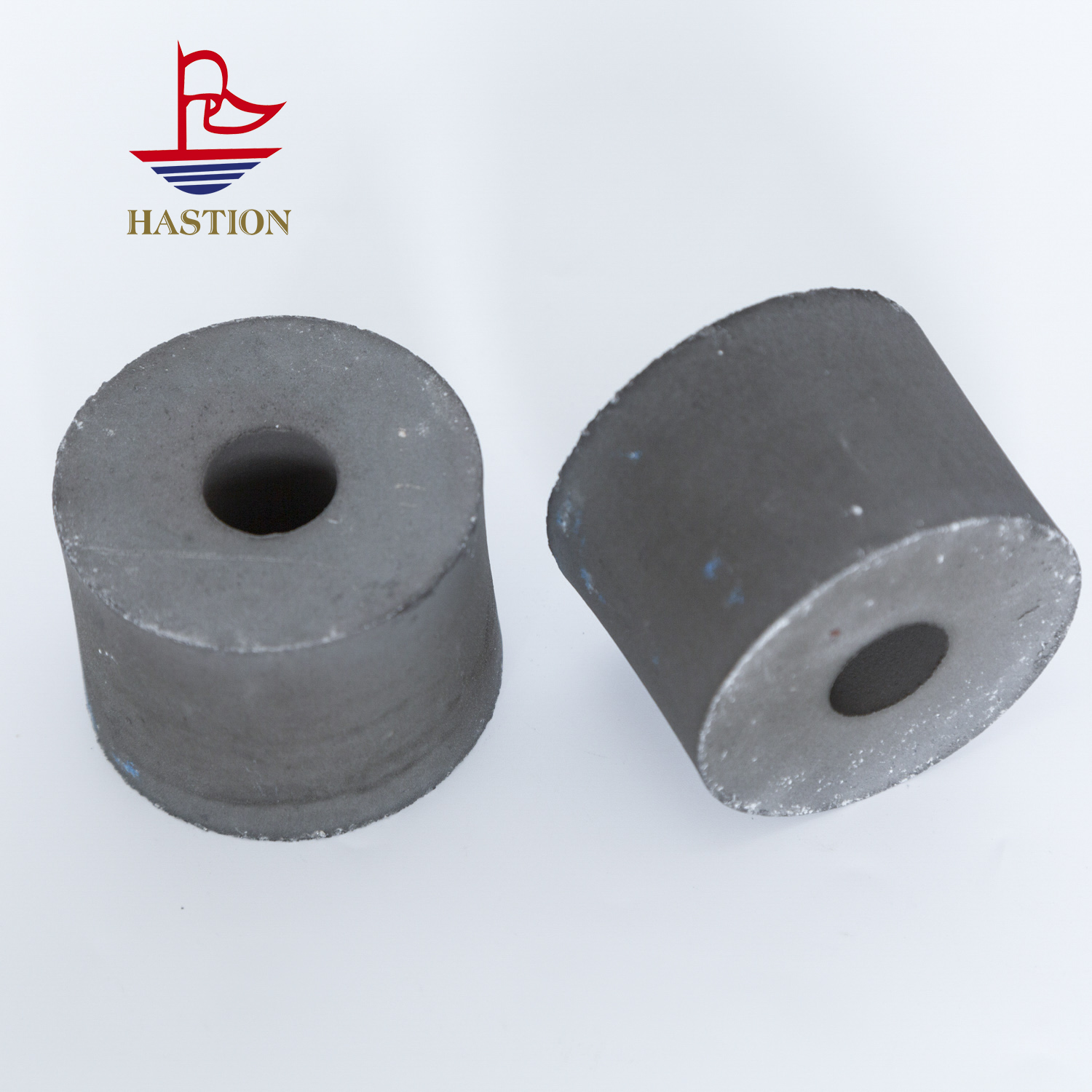

Titanium carbide rods - mining machinery parts

Titanium carbide (TiC)-based cemented carbide round rods are a critical advanced material in high-end manufacturing. Owing to their exceptional corrosion resistance, these rods exhibit outstanding stability in humid, acidic, and alkaline service environments—resisting rust formation and functional degradation. Their thermal conductivity is approximately 15% higher than that of conventional tungsten carbide (WC)-based rods, enabling efficient dissipation of cutting-induced heat and thereby mitigating thermally driven tool wear. With a bending strength of up to 2500 MPa, the material combines high hardness with requisite fracture toughness, significantly reducing susceptibility to impact-induced fracture during operation. In aerospace applications, TiC-based rods serve as feedstock for precision cutting tools employed in the machining of turbine blades, combustion chambers, and other mission-critical engine components—consistently meeting stringent dimensional accuracy and surface integrity requirements. Furthermore, advances in additive manufacturing have enabled the production of spherical, flowable TiC-based powders suitable for laser powder bed fusion (LPBF) and binder jetting processes; sintered parts fabricated via these routes achieve >99.5% of theoretical density and mechanical performance comparable to conventionally sintered counterparts. In photovoltaic manufacturing, TiC-reinforced cutting tools enable ultra-precise dicing of silicon wafers, maintaining thickness tolerance within ±1 μm and contributing directly to enhanced solar cell conversion efficiency. Collectively, these attributes underscore the material’s strategic importance and broad applicability across multiple high-value industrial sectors.

Send product request

Other supplier products

| Titanium carbide guide wheels for industrial transmission | Hard alloy titanium carbide guide wheels exhibit excellent thermal shock resistance. When subjected to rapid temperature changes—from room te... | |

| Titanium carbide hard alloy guide wheels - accessories | The installation holes of the guide wheel have high precision, and the fit clearance with the shaft can be controlled within 0.005-0.01mm, ensuring... | |

| Carbide guide rollers for wire and cable production | Lighter than Tungsten carbide roller by 55%, Lighter than tool steel than 20%, so the guide roller accelerates from standstill to 35,000 rpm, witho... | |

| Titanium carbide rods - Corrosion resistance | The titanium carbide hard alloy guide wheel exhibits outstanding thermal shock resistance, maintaining structural integrity without cracking under ... | |

| Ultrafine Nano Titanium Carbide Powder | Titanium carbide TiC powder are mainly used in the steel-bonded cemented carbide, cermet components, tungsten-cobalt-titanium cemented carbide and ... |

Same products

| 3D printing spherical titanium carbide powder | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This batch of titanium carbide powder (TiC) has a purity of over 99.5%, with a particle size cont... | |

| Titanium carbide hard alloy drive wheel - Specialized | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | The titanium carbide (TiC) guide wheel is fabricated via high-temperature powder metallurgy sinte... | |

| Industrial guide wheels, titanium carbide wear-resistant alloy | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This carbonized titanium (TiC) guide wheel is formed by high-temperature sintering of 99.5% pure ... | |

| Unfinished bar stock - heat treatable | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This high-purity titanium carbonitride (TiCN) round bar is fabricated via hot-pressing and sinter... | |

| Steel-based titanium carbide hard alloy round bar | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This carbonitride round bar (TiC) is formed by hot-pressing and sintering 99.5% high-purity carbo... |