Industrial titanium carbide rods are wear-resistant

The production process of this round bar is extremely strict, from the purity control of titanium carbide powder (purity ≥99.5%) to the precise regulation of sintering temperature (about 1500℃), every step affects the final performance. The finished product features excellent dimensional stability. Under temperature variations ranging from -50℃ to 300℃, its coefficient of thermal expansion is only 6×10⁻⁶/℃, which is significantly lower than that of metal materials, ensuring the precision of precision tools in various environments. It is widely used as wear-resistant inserts in automotive molds, capable of withstanding long-term high-pressure friction without easy wear, thus extending the service life of the molds. With the development of 3D printing technology, hard alloy titanium carbide round rods have also been made into powder for 3D printing precision parts. The density of the printed parts can reach 99.5% of the theoretical density, and their performance is comparable to that of traditional sintered parts. It is used as a silicon wafer cutting tool in the photovoltaic industry, which can ensure that the thickness error of the silicon wafer is controlled within ±1μm and improve the conversion efficiency of solar cells. This versatility makes it an indispensable material in the high-end manufacturing field.

Send product request

Other supplier products

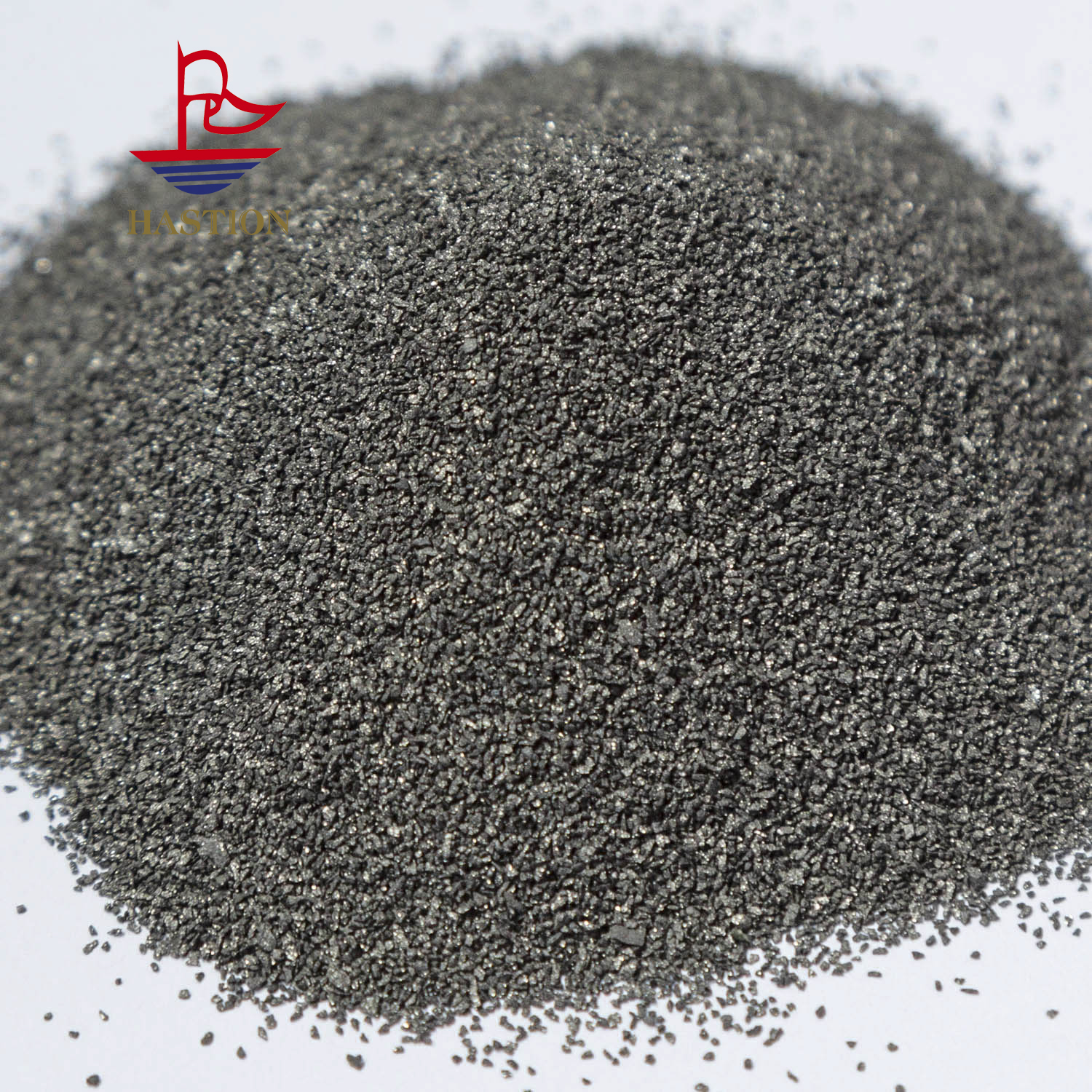

| Titanium carbide powder with low impurity content | Titanium carbide powder has excellent chemical stability, insoluble in water, hydrochloric acid, sulphuric acid and other common acids and alkali... | |

| High-strength titanium carbide rods - machine tool parts | Titanium carbide round rods of cemented carbide are high-performance rods made by powder metallurgy process, with titanium carbide as the main hard... | |

| High-precision titanium carbide hard guide wheel | This type of guide wheel can be customized with groove shapes—such as V-shaped, U-shaped, or semi-circular—based on the specifications ... | |

| Guide wheels for harsh working environments | Titanium carbide guide wheel is a high-performance transmission component made of titanium carbide as the core material. It is extremely high har... | |

| Supersonic spraying of chromium carbide powder | Chromium carbide powder is a gray powder with high hardness, wear and high temperature corrosion resistance properties, often added as a hard phase... |

Same products

| 3D printing spherical titanium carbide powder | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This batch of titanium carbide powder (TiC) has a purity of over 99.5%, with a particle size cont... | |

| Titanium carbide hard alloy drive wheel - Specialized | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | The titanium carbide (TiC) guide wheel is fabricated via high-temperature powder metallurgy sinte... | |

| Industrial guide wheels, titanium carbide wear-resistant alloy | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This carbonized titanium (TiC) guide wheel is formed by high-temperature sintering of 99.5% pure ... | |

| Unfinished bar stock - heat treatable | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This high-purity titanium carbonitride (TiCN) round bar is fabricated via hot-pressing and sinter... | |

| Steel-based titanium carbide hard alloy round bar | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This carbonitride round bar (TiC) is formed by hot-pressing and sintering 99.5% high-purity carbo... |