Titanium carbide alloy rods for efficient processing materials

Compared with traditional high-speed steel bars, the cutting speed of carbide titanium round bars can be increased by 3-5 times, significantly reducing processing time in batch production. Its microstructure is uniform, and the grain size can be controlled below 1 μm, ensuring consistent performance of the bar at all parts and avoiding tool failure due to material inconsistency. In the mold industry, the cold stamping mold inserts made of it have a lifespan 50-100 times longer than those made of steel, significantly reducing the replacement frequency and production costs. With the development of 3D printing technology, hard carbide titanium round bars have also been made into powder for 3D printing of precision parts, with the printed parts having a density of up to 99.5% of the theoretical density, and their performance being comparable to that of traditional sintered parts. It is used in the photovoltaic industry for silicon wafer cutting tools, ensuring that the thickness error of the silicon wafer is controlled within ±1 μm, and improving the conversion efficiency of solar cells. This versatility makes it an indispensable material in the high-end manufacturing field.

Send product request

Other supplier products

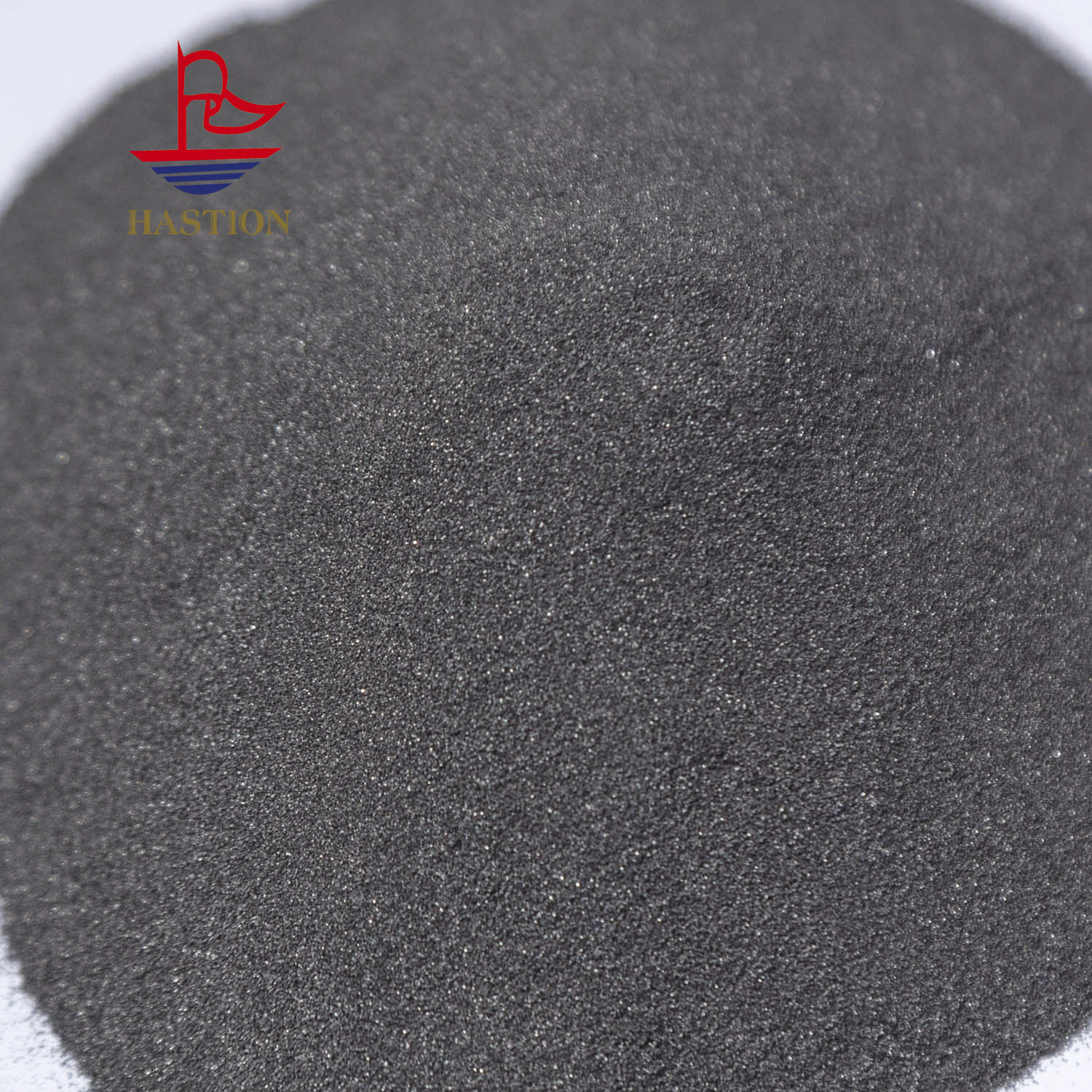

| Ultrafine Nano Titanium Carbide Powder | Titanium carbide TiC powder are mainly used in the steel-bonded cemented carbide, cermet components, tungsten-cobalt-titanium cemented carbide and ... | |

| Titanium carbide hard rods - preferred for tool manufacturing | Titanium carbide cemented carbide round rods are high-performance components fabricated through a powder metallurgy process, with titanium carbide ... | |

| Industrial titanium carbide rods - fast custom processing | Titanium carbide round rods of cemented carbide are high-performance rods made by powder metallurgy process, with titanium carbide as the main hard... | |

| Large specific surface area, high activity chromium carbide powder | Chromium carbide powder is a grey-black powder with a melting point of about 1890°C and a Mohs hardness of 8.5. It has excellent wear resistanc... | |

| Chromium carbide powder with outstanding forming effect | Chromium carbide powder is a grayish-black powder with a melting point of approximately 1890℃ and a Mohs hardness of 8.5. It features excellent wea... |

Same products

| 99.5% high-purity chromium carbide powder | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | Chromium carbide powder has excellent wetting properties and is firmly bonded to metal substrates... | |

| Carbonitride powder for plastic modification | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | The particle morphology of this powder can be controlled, and it can be made into spherical, near... | |

| Titanium carbide hard alloy drive wheel accessory | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This guide wheel is customizable with various groove geometries—including V-shaped, U-shape... | |

| Industrial titanium carbide alloy drive wheels | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This guide wheel can be customized with various slot shapes according to the specifications of wi... | |

| Wear-resistant steel-bonded hard alloy round bar | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | Titanium carbide (TiC)-based cemented carbide round rods exhibit exceptional electrical conductiv... |