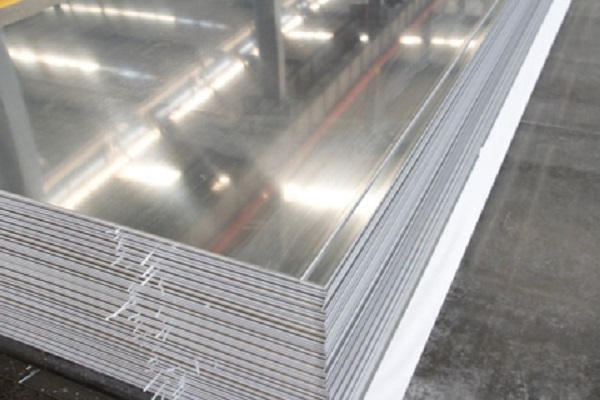

6082 alloy aluminum sheets product for sale

6082 alloy is a heat-treated strengthenable alloy with good formability, weldability, machinability, and medium strength. It can maintain good operability after annealing. It is mainly used in mechanical structures, including rod Materials, plates, pipes and profiles. This alloy has similar but not identical mechanical properties to 6061 alloy, and its -T6 state has higher mechanical properties. Alloy 6082 is a very common alloy product in Europe and has a high application in the United States. It is suitable for processing raw materials, seamless aluminum pipes, structural profiles and custom profiles. 6082 alloy usually has good processing characteristics and good anode reaction performance. Common anode reaction methods include removing impurities and dyeing, coating and so on.

6082 aluminum alloy plate performance advantages:

Smallium alloy 6082 combines excellent solderability, brazeability, corrosion resistance, formability and machinability. The 0-0 and T4 states of alloy 6082 are suitable for bending and forming. The -T5 and -T6 states are suitable for good machinability. Some specific processes require the use of chip separators or other special processes to help separate chips. Alloys usually have good processing characteristics and good anode reaction performance; they are widely used in mechanical parts, forgings, commercial vehicles, railway structural parts, shipbuilding, etc.

Production equipment

Features

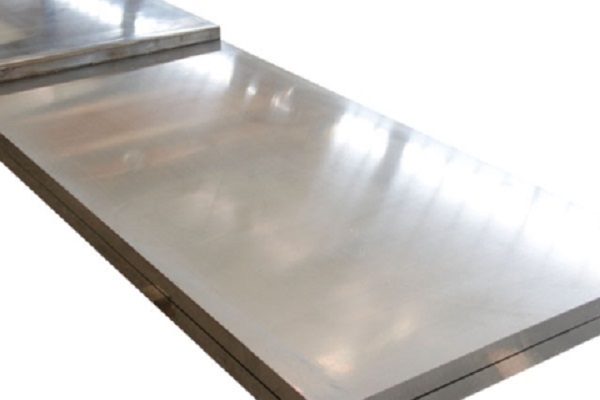

1. Good formability and weldability. 2. High intensity. 3. Good usability and excellent interface characteristics. 4. Easy to process and easy to coat. 5. Good corrosion resistance and oxidation resistance.

Heat treatment process:

1. Smelting 6082 alloy is characterized by containing Mn, Mn is a refractory metal, and the melting temperature should be controlled at 740-760 ℃. Evenly stir more than two times before sampling to ensure that the metal is completely melted, the temperature is accurate, and the composition is uniform. After stirring, take a sample in the middle of the depth of the aluminum liquid, and the left and right sides of the furnace for analysis. After passing the break, you can convert it.

2. Purification and casting After the melt is transferred to a still furnace, powder spraying and jet refining are performed with nitrogen and a refining agent. The refining temperature is 735-745 ° C for 15 minutes, and the refining is left for 30 minutes. Through this process, gas is removed, slag is removed, and the melt is purified. There are two filtering devices between the mold and the furnace mouth during melting casting. The furnace mouth has a foam ceramic filter plate (30PPI) for filtration. Before casting, it is filtered with a 14-mesh glass fiber silk cloth to fully filter out oxides and slag in the melt.

The casting temperature of 6082 alloy aluminum plate is high (compared with the normal process of 6063 aluminum plate), the casting speed is low, and the water flow is large. The above process must be strictly controlled and cannot exceed the range, otherwise it may easily lead to casting failure.

Send product request

Other supplier products

| 1mm thick aluminium sheet | 1mm thick aluminium sheet is used for aluminum-plastic panels, which is actually short for aluminum-plastic composite panels. Aluminum-plastic co... | |

| 3004 aluminum sheet for sale | The ">3004 aluminum plate has good formability, adhesion, and corrosion resistance. For processing parts and components that require good form... | |

| 6082 alloy aluminum sheets product for sale | 6082 alloy is a heat-treated strengthenable alloy with good formability, weldability, machinability, and medium strength. It can maintain good oper... |

Same products

| 1050/1060/3003/5052/5083 Aluminum Discs for Cookware and Traffic Signs | Seller: Henan Hongchang Aluminum Co., Ltd. | Aluminum discs (also called aluminum circles) are produced from high-quality aluminum coils throu... | |

| Painted Aluminum for PP/ROPP Cap | Seller: Zhengzhou Haomei Industrial Co., Ltd. | It is applicable for cosmetics, yogurt caps, pharmaceutical bottle caps, milk tear-off caps, anti... | |

| Marine Grade Aluminum 5083 | Seller: Zhengzhou Haomei Industrial Co., Ltd. | With 5083 aluminum sheet replacing traditional steel ship, each ship can save about 8-100 tons of... | |

| 5052 Aluminum Sheet Plate | Seller: Zhengzhou Haomei Industrial Co., Ltd. | 5052 Aluminum Sheet/Plate belongs to Al-Mg alloy with magnesium as its main alloy elements. Of ot... | |

| High quality 3mm, 4mm, 5mm, 8mm 5083 H116/H321/H112 aluminum plates for ships, DNV/CCS certified sheets | Seller: Henan Hongchang Aluminum Co., Ltd. | Product information: 5083 aluminum alloy belongs to the Al-Mg series of rust-proof aluminum alloy... |