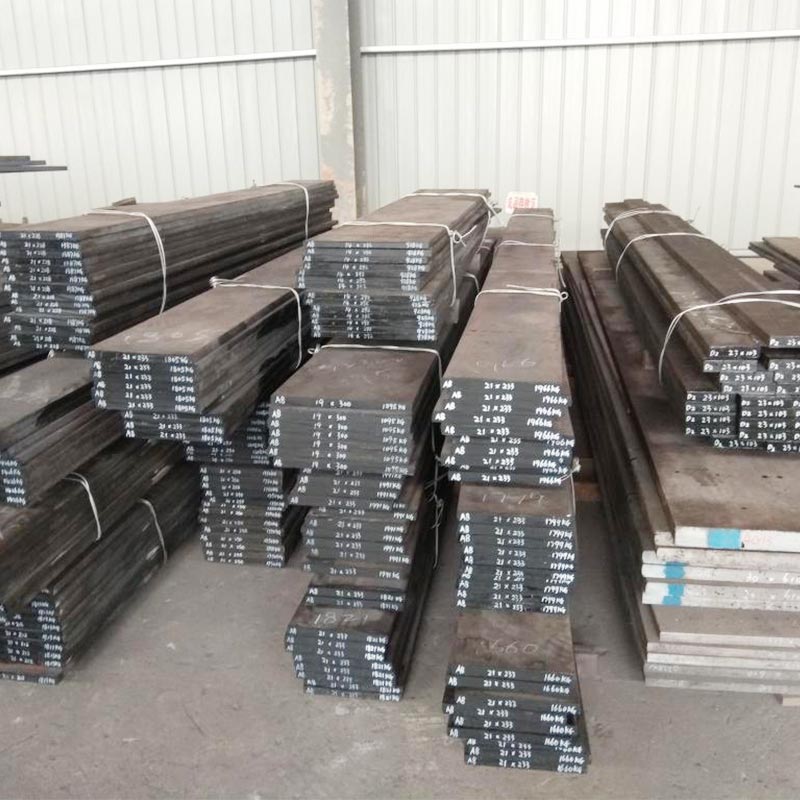

Air-hardening A8 Mod Cold Work Tool Steel Plates Bars Sheet Forgings

Product Details

A8 is an air-hardening cold work tool steel. It exhibits good wearing qualities with excellent toughness characteristics. It is well suited for many metals working dies and punches, which operate in the hardness of Rockwell C 55-60.

Applications:Punches, drift pins, pneumatic tools, chuck jaws, hammers, hot rolls, and hot and cold shear knives.

Quality Standard:ASTM A681 – 08 Standard Specification for Tool Steels Alloy.

Website:

Chemical Composition(%)

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

HEAT TREATMENT

Preheating: Heat at a rate not exceeding 400°F per hour to 1400-1450°F and equalize.

Austenitizing: Heat slowly from the preheat. Furnace or Salt: 1825-1850°F. Soak for 30 minutes for the first inch of thickness, plus 15 minutes for each additional inch.

Annealing: Annealing must be performed after hot working and before rehardening.

Heat at a rate not exceeding 400°F per hour to 1550°F, and hold at temperature for 1 hour per inch of maximum thickness; 2 hours minimum. Then cool slowly with the furnace at a rate not exceeding 50°F per hour to 1000°F. Continue cooling to ambient temperature in the furnace or in air. The resultant hardness should be a maximum of 241 HBW.

Hardening: Air, pressurized gas, or interrupted oil to 150-125°F.

special steel supplier:

Note: Sizes over 5 inches in cross section may not achieve full hardness by cooling in still air. It is usually necessary to increase the quench cooling rate between 1400 to 900°F by using an air blast, pressurized gas, or an interrupted oil quench. For the oil quench, quench until black, about 900°F, then cool in still air to 150-125°F.

Tempering: Temper immediately after quenching. Hold temperature for 1 hour per inch of thickness, 2 hours minimum, then air cool to ambient temperature. The typical tempering range is 300 to 600°F. Double tempering is recommended for tempering temperatures of 900°F and higher.

To minimize internal stresses in cross sections greater than 6 inches and to improve stability in tools that will be EDM’d after heat treatment, a soaking time of 4 to 6 hours at the tempering temperature is strongly recommended.

,based on the over one hundred years’s production history of in Huangshi, provide professional services and material for cutting tool companies, mould companies and other industrial enterprises all over the world for years.

Send product request

Other supplier products

| Cr12Mov Cold Work Tool Steel Plates Bars Sheet Forgings | Used to manufacturing all kinds of moulds and tools with comparatively larger cross sections and complex shapes, which can bear heavy shock loads.... | |

| 1.2316/3Cr17Mo Plastic Mold Tool Steel Plates Bars Sheet Forgings | Product Details Specification Round bar Diameter(mm) Length(mm) - Forged round bar:φ50~450 2000~6000 - Rolled round bar:&... | |

| Air-hardening A8 Mod Cold Work Tool Steel Plates Bars Sheet Forgings | Product Details A8 is an air-hardening cold work tool steel. It exhibits good wearing qualities with excellent toughness characteristics. It is we... | |

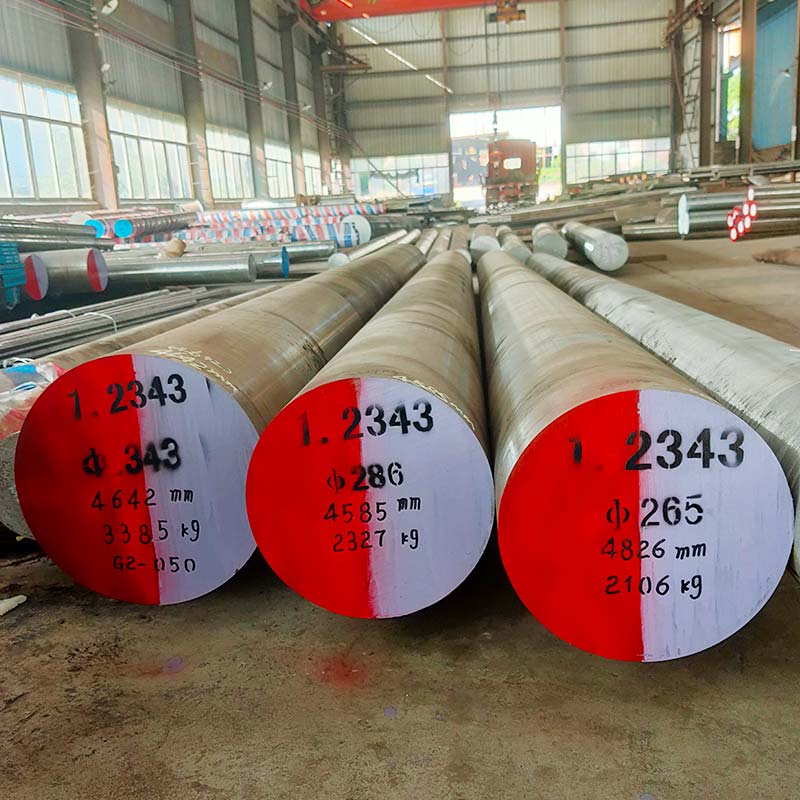

| H11/1.2343 Hot Work Tool Steel Following NADCA standard | Product Details Chemical Composition (%) Standard Steel Grade C Si Mn P S Cr Mo V W DIN - ASTM H11 ... | |

| S5 Cold Work Tool Steel Plates Bars Sheet Forgings | Preheating: Heat at a rate not exceeding 400°F per hour (222°C per hour). For complex and large tools, heat to 1150-1250°F (621-677&de... |

Same products

| CK800 Flat Bed Lathe | Seller: Taizhou Eastern CNC Technology Co., Ltd. | The CK800 Flat Bed Lathe carriage in the machine tool adopts a double tool holder design, which i... | |

| stainless steel filter elements | Seller: ZHUAN LV FILTRATION | stainless steel filter elements Stainless Steel Filter Cartridges/Elements Stainless Stee... | |

| Stainless Steel Banding Strap Strip for Pole Clamp | Seller: Nanjing Suntay Steel Co., Ltd | Stainless Steel strappingis ideal for cable and pipe banding applications that require various bu... | |

| Aluminum Clad Steel Wire | Seller: Nanjing Suntay Steel Co., Ltd | Typical Application:Power line crossing water, Power line in industrial ,semi-industrial or coast... | |

| Steel Wire Rope For Wind Power Generation | Seller: Nanjing Suntay Steel Co., Ltd | Steel wire rope for wind power generationis a high-performance produtc specially designed and man... |