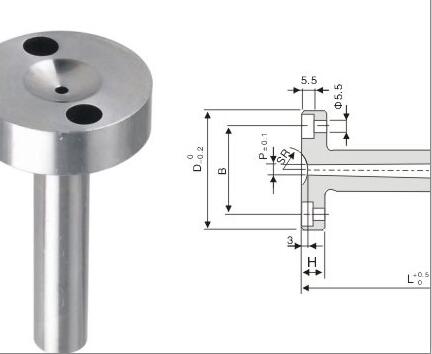

Shoulder Ejector Sleeve Pins

| Material | InnerHardness | SurfaceHardness | Heat Treatment |

| FDAC | HRC38°±2° | HV1000°±100° | Nitrided |

| HRC52°±2° | HRC52°±2° | Vacuumed |

JH Ejector Sleeve ranges from straight, step, multiple step, or thin walled sleeves. Nitrided SKD61 being the most commonly used steel in ejection molding. However other materials as well as SKD61 including, but not limited to. Ejector Sleeves can be manufactured to a working hardness designed to your application. We also offer a variety of surface treatments such as Nitride, Titanium Nitride and Vacuumed to name a few. Sleeves ranging from under 10mm long to 1000mm long are available. Inside and outside diameters are ground concentric to ensure proper alignment. If you need we could reach the tolerance to 0.002mm

Send product request

Other supplier products

| MateriaSpure Bushing-A Type JH025 | Inner HardnessSurface HardnessHeat Treatment S45CSR section HRC50°~55°Partial HRC60°±2°HRC60°±2°Vacuumed SKD1... | |

| Straight Ejector Sleeve Pins | JH Ejector Sleeve ranges from straight, step, multiple step, or thin walled sleeves. Nitrided SKD61 being the most commonly used steel in ejection ... | |

| MOULD PART Positioning Components YK30 Taper Block Sets JH044 | Attentions given by positioning component supplier who wholesales high quality positioning component: Remember the following points as you positio... | |

| Shoulder Ejector Sleeve Pins | Material InnerHardness SurfaceHardness Heat Treatment FDAC HRC38°±2° HV1000°±100° Nitrided HRC5... | |

| CP-CPS-CPH-CPHS Gas Spring-Higher Forces | CP-CPS-CPH-CPHS Higher Forces Nitrogen Gas Spring series: • Higher forces in the same diameter. • Higher loading pressure. • Conn... |

Same products

| DC GB/T Charging Connector | Seller: Aupins Technology Co., Ltd | DC GB/T Charging Connector GB/T Charging Connector is widely used in the DC charging system of e... | |

| Buy Custom Purple Silicone Rubber Bracelets/Wristbands | Seller: Yppromotion | Purple rubber wristbandsmade by YP Promotion are beautiful and perfect for couples. Custom orders... | |

| SAE J1772 Charging Connector | Seller: Aupins Technology Co., Ltd | AP SAE J1772 combo AC EV charging plug conforms to sae j1772 plugprovisions and requirements. Thi... | |

| GB/T Charging Connector | Seller: Aupins Technology Co., Ltd | GB T ChargingConnector is widely used in the AC charging system of electric vehicles and conforms... | |

| DC GB/T Charging Connector | Seller: Aupins Technology Co., Ltd | GB/T Charging Connector is widely used in the DC charging system of electric vehicles and conform... |