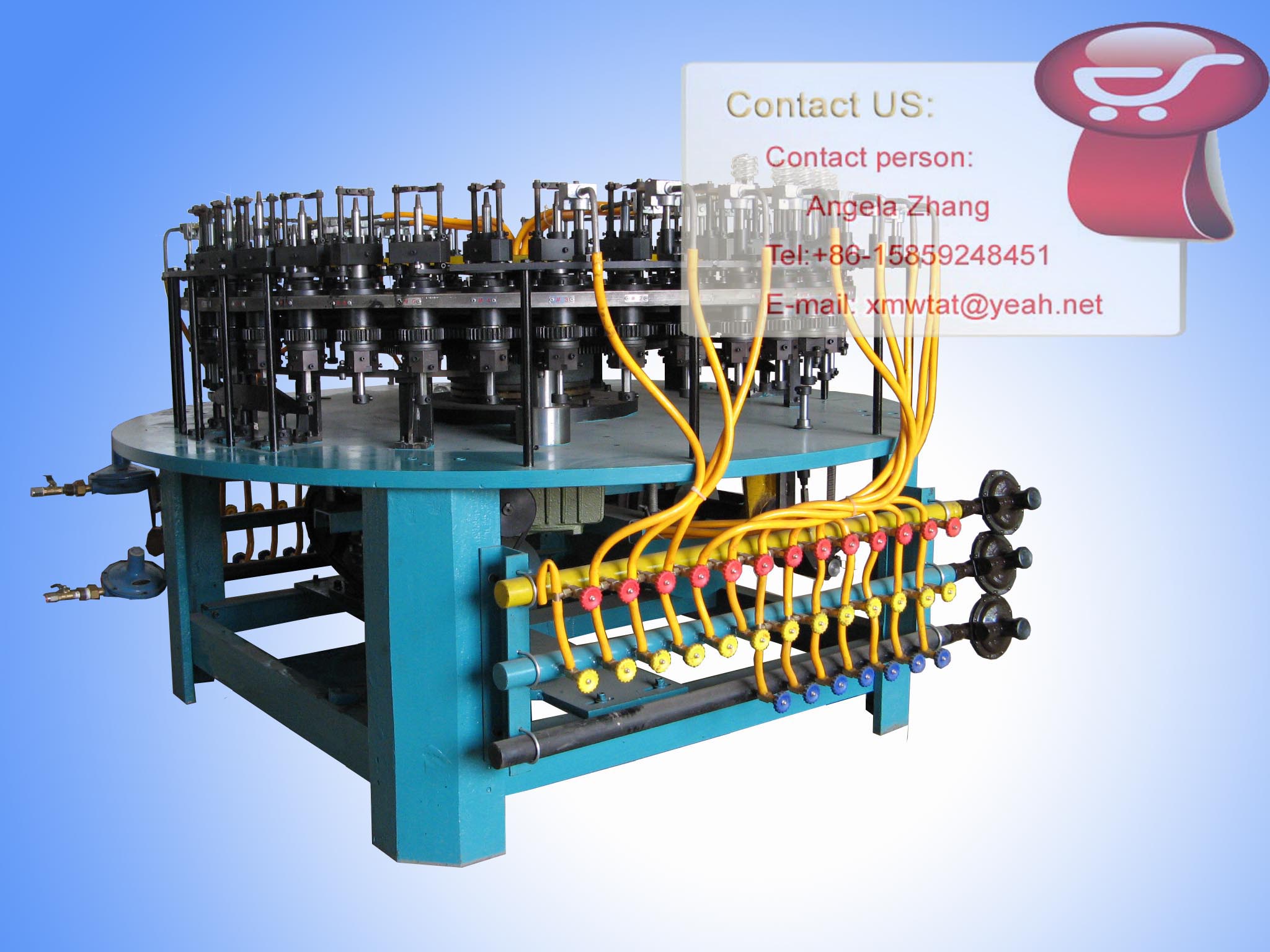

Burner leg sealing machine-CFL making machine

1.Suitable for sealing semi-spiral lamp. Capacity: 1250 Pcs/Hour. Sealing both lamp tubes simultaneously.

2.Automatic loading, automatic tubes shifting, automatic Stem loading, automatic sealing and automatic unloading.

3.Two stem feeding ways: automatically and manually.

4.Parameter setting via PLC and touch panel.

5.Qualified rate: > 95%.

6.Advantages:

1) Parallel clamping configuration ensuring stable operation and high qualified rate; 2) Automatic tube loading/unloading; 3) Less worker needed; 4) High efficiency.

Other supplier products

|

|

Phosphor coating machine-CFL making machine |

Descriptions:

1.Phosphor coating for T2, T3, T4, T5 spiral and semi-spiral tubes, also for other lamp sizes if suitable jigs are adopted.

2.Sp... |

|

|

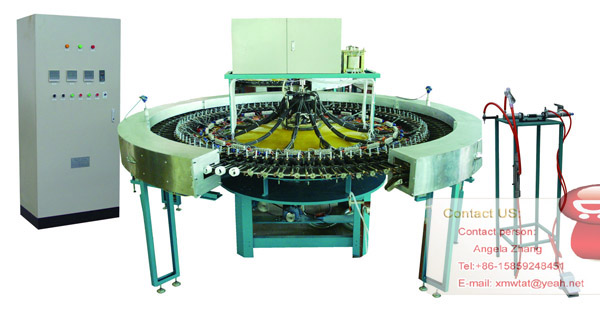

CFL burner exhaust machine |

A: Specifications:

1.48 heads, for producing U-shape, semi-spiral, spiral, T4/T5 straight and round tubes.

2.3 seconds per head, 1200pcs/hour, adj... |

|

|

Burner leg sealing machine-CFL making machine |

1.Suitable for sealing semi-spiral lamp. Capacity: 1250 Pcs/Hour. Sealing both lamp tubes simultaneously.

2.Automatic loading, automatic tubes shif... |

All supplier products

Same products