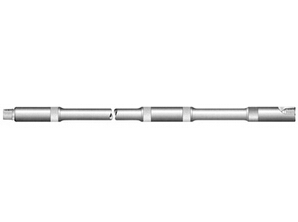

Integral drill pipe

| Our company's drill pipes are in accordance with API 5D, API SPEC 7 Standards. The material of drill pipe body are chosen by the 1&3 group of API 5D.(Group 1-Grade E75; Group 3-Grade X95, G105, S135). The choice of tool joints is according to the customers’requirements, and the tool joints are up to API SPEC7 Standards. |

First,usesthedoubleledgeattachmentdrillrodthereason

★The ordinary API male union because attaches the thread outer diameter limit, the API drill rod has pair of contradictory: Attaches anti turns the intensity and the male union flushing port size. The S135 high strength drill rod, the contradiction is in particular more prominent

★attaches the flushing port size to increase, attaches antiturns the intensity to reduce, antiturns the strength ratio with the tube body to reduce; (2) attaches flushing port minification, attaches antiturns the intensity to increase, but the hydraulic horsepower loss increases.

How therefore both can increase the flushing port size, and can not reduce, even increases the attachment anti- to turn the intensity.

★Bohai Sea can a gram company produce the double ledge attachment drill rod can solve this problem well: Both may increase the attachment flushing port size, reduces the hydraulic horsepower to lose, and can enhance the attachment anti- to turn the intensity, causes to attach anti- turns the intensity to be higher than the tube body antito turn the intensity.

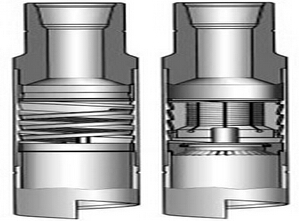

Second,doubleledgeattachmentdrillrodprinciple:

★Ordinary API attaches anti- turns the intensity by the outside ledge contacted area, the diameter and male union thread pitch diameter place thickness decided that, these attach the outer diameter and the male union flushing port size limit. The double ledge attachment has two ledges: Is outside the ledge, another is in the ledge. In the ledge plays to increases anti- turns the intensity the role, after causes the drilling rod coupling flushing port suitably to increase, but also can guarantee the attachment antito turn strongly is higher than the tube body anti- to turn the intensity.

★Turns on lathe after the double ledge attachment gathers, outside the ledge goes against, in the ledge 留有 the very small gap outside, by guarantees the ledge to be able to play to the seal role, after the screw on achieved the certain torque in the ledge goes against, after achieved on the torque, in the ledge anti- turns the intensity to have an effect.

Third,doubleledgeattachmentperformanceandmerit:

★The double ledge attachment performance attached list shows, the merit is the attachment flushing port may suitably increase, like the S135 drill rod male union flushing port size 2-3/4 "increases from the API request to 3-1/4", but attaches and the tube body anti- turns the strength ratio from 0.86 to increase to 1.00, achieved both has been able suitably to increase the flushing port size and to be able to enhance attaches anti- turns the intensity the goal, enhanced the drill rod whole anti- to turn the intensity, at the same time also could meet the well drilling need well. At the same time the double ledge attachment drill rod and the ordinary API drill rod may exchange.★Double ledge attachment drill rod use matters needing attention:

★A.When screw on certainly must achieve the stipulation the tightening torque, because the double ledge attachment anti- turns strength ratio same specification API to attach anti- turns the intensity to be high, therefore the double ledge drill rod tightening torque also should correspondingly enhance. B.When transporting and use drill rod in pays attention must bump into and injure the ledge end surface, in drills on Taiwan to put the column in particular under to be supposed to have the bolster. The double ledge attachment drill rod repairs the buckle:

★The double ledge attachment drill rod and the ordinary API drilling rod coupling may carry on equally repairs the buckle, only must pay attention is in the male and female the ledge length certainly must control, this also is the double ledge attachment difficulty, can a gram company be possible to provide the technical support in this aspect Bohai Sea. Moreover the pair of ledge attachment drill rod and the ordinary API drill rod definitely may exchange the use.

★Along with the well drilling depth unceasing increase, the complex stratum appears unceasingly, specially contains the sulfur stratum increasing, has safely brought the test for the well drilling, once when well drilling will appear the hydrogen sulfide, the drilling tool can break suddenly in the very short time, the hazardous nature will be extremely big.

★In the last few years more and more many users all proposed the antisulfur drill rod demand. Therefore Bohai Sea could the gram establish the anti- sulfur drill rod development from 2003, at present has had produces the C105S grade of steel the antisulfur drill rod technology, at present in order to adapt the Talimu deep well antisulfur drill rod request, the company was carrying on the C120S drill rod the development.

★What at present in the API series drill rod the intensity is highest is the S135 grade of steel. But along with the well drilling depth unceasing increase, also unceasingly is enhancing to the drill rod intensity request.

★In view of this kind of situation, Bohai Sea could gram and NKK develops the V150 drill rod, the attachment intensity also had from 120Ksi enhances to 135Ksi, after managed the body and the attachment enhances the intensity still to have the enough resilience, had the higher comprehensive machine capability, will satisfy the next extra-deep well the well drilling need.

★The tungsten carbide bears the abrasive belt series.

★The tungsten carbide bears the abrasive belt to have the very high resistance to wear, after the attachment welds this kind to bear the abrasive belt, the attachment is life-long cannot wear. Minute S1000, S3000, the S6000 three kind of series bear the abrasive belt, S1000 are the fine grain tungsten carbide pellets, can avoid the drive pipe wearing well, S3000 is the large grain tungsten carbide pellet, the grain density is high, has the very high resistance to wear, suits in uses in the open hole, S6000 also is the large grain tungsten carbide pellet, but the majority of tungsten carbides pellet in the wear-resisting generation, like this both may the very good local constable protect the drive pipe, and can teach to avoid the drive pipe the attrition. And already may the built-up welding be even -like bears the abrasive belt, also may the built-up welding bulge type bear the abrasive belt, also the built-up welding together bears the abrasive belt in the box 18 inclines, prevents 18 inclines the attrition.

★The ARNCO series bears the abrasive belt.

★The ARNCO series bears the abrasive belt to favor the splice case, after bears the abrasive belt to wear may again the built-up welding, divides ARNCO 100, ARNCO 200, the ARNCO 3,003 kinds bears the abrasive belt.

★ARMACOR bears the abrasive belt.

★This kind bears the abrasive belt and ARNCO bears the abrasive belt to be similar, favors the splice case, in overseas has some users to use

this kind to bear the abrasive belt. Bohai Sea can the gram be possible to act according to the user above the request built-up welding each kind of series to bear the abrasive belt.

CENERALDATA

1.MECHANICALPROPERTIESOFDRILLPIPE

|

Grade |

YieldStrength |

TensileStrength |

Elongation |

||||

|

min |

max |

min |

min.percent |

||||

|

Psi |

MPa |

Psi |

MPa |

Psi |

MPa |

in2in.(50.88mm) |

|

|

E-75 |

75,000 |

517 |

105,000 |

724 |

100,000 |

689 |

API5D |

|

X-95 |

95,000 |

655 |

125,000 |

862 |

105,000 |

724 |

API5D |

|

G-105 |

105,000 |

724 |

135,000 |

931 |

115,000 |

793 |

API5D |

|

S-135 |

135,000 |

931 |

165,000 |

1138 |

145,000 |

1000 |

API5D |

Tooljoints

|

YieldStrength |

TensileStrength |

Minimum |

||

|

Psi |

MPa |

Psi |

MPa |

Elongation,percent |

|

120,000 |

827 |

140,000 |

965 |

13 |

SOURSERVICEDRILLPIPE

Fordrillinghighpressuresourgaswell,BHNK'sspecialgradedrillpipeBNKC958/ToolJointisavailale.

|

Grade |

YieldStrength |

TensileStrenght |

Elongation |

Hardness |

||||

|

min |

max. |

min. |

min.percent |

max. |

||||

|

Psi |

MPa |

Psi |

MPa |

Psi |

MPa |

in2in(50.88mm) |

(HRC) |

|

|

BNKC95S |

95,000 |

655 |

110,000 |

757 |

105,000 |

724 |

API5D |

25.4 |

|

BNKC105S |

105,000 |

724 |

135,000 |

931 |

115,000 |

793 |

Sameasabove |

28.0 |

SOURSERVICETOOLJOINT

|

Grad |

YieldStrength |

TensileStrenght |

Elongation |

Hardness |

||||

|

min |

max. |

min. |

min.percent |

max. |

||||

|

Psi |

MPa |

Psi |

MPa |

Psi |

MPa |

in2in(50.88mm) |

(HRC) |

|

|

BNKTJ95S |

95,000 |

655 |

110,000 |

757 |

105,000 |

724 |

11 |

25.4 |

|

BNKTJ105S |

105,000 |

724 |

120,000 |

827 |

115,000 |

792 |

10 |

28 |

|

BNKTJ110S |

110,000 |

758 |

125,000 |

861 |

120,000 |

827 |

10 |

29.0 |

|

Size |

Nominal |

Pipe |

ToolJoint |

|||||

|

Pipe |

Upset |

Grade |

Designation |

Outside |

Inside Diameterofpin |

|||

|

Wall |

Inside |

|||||||

|

in(mm) |

Lbs |

in(mm) |

in(mm) |

|||||

|

23/8(60.3) |

6.65 |

0.280(7.11) |

1.815(46.1) |

EU |

E75 |

*NC26(23/8IF) |

33/8(85.7) |

13/4(44.5) |

|

23/8(60.3) |

6.65 |

0.280(7.11) |

1.815(46.1) |

EU |

X95 |

*NC26(23/8IF) |

33/8(85.7) |

13/4(44.5) |

|

23/8(60.3) |

6.65 |

0.280(7.11) |

1.815(46.1) |

EU |

G105 |

*NC26(23/8IF) |

33/8(85.7) |

13/4(44.5) |

|

27/8(73.0) |

10.40 |

0.362(9.19) |

2.151(54.6) |

EU |

E75 |

*NC31(27/8IF) |

41/8(104.8) |

21/8(54.0) |

|

27/8(73.0) |

10.40 |

0.362(9.19) |

2.151(54.6) |

EU |

X95 |

*NC31(27/8IF) |

41/8(104.8) |

2(50.8) |

|

27/8(73.0) |

10.40 |

0.362(9.19) |

2.151(54.6) |

EU |

G105 |

*NC31(27/8IF) |

41/8(104.8) |

2(50.8) |

|

27/8(73.0) |

10.40 |

0.362(9.19) |

2.151(54.6) |

EU |

S135 |

*NC31(27/8IF) |

43/8(111.1) |

15/8(41.3) |

|

31/2(88.9) |

9.50 |

0.254(6.45) |

2.992(76.0) |

EU |

E75 |

*NC38(31/2IF) |

43/4(120.7) |

3(76.2) |

|

31/2(88.9) |

13.30 |

0.368(9.35) |

2.764(70.2) |

EU |

E75 |

NC38(31/2IF) |

43/4(120.7) |

211/16(68.3) |

|

31/2(88.9) |

13.30 |

0.368(9.35) |

2.764(70.2) |

EU |

X95 |

*NC38(31/2IF) |

5(127.0) |

29/16(65.1) |

|

31/2(88.9) |

13.30 |

0.368(9.35) |

2.764(70.2) |

EU |

G105 |

NC38(31/2IF) |

43/4(120.7) |

211/16(68.3) |

|

31/2(88.9) |

13.30 |

0.368(9.35) |

2.764(70.2) |

EU |

G105 |

NC38(31/2IF) |

43/4(120.7) |

29/16(65.1) |

|

31/2(88.9) |

13.30 |

0.368(9.35) |

2.764(70.2) |

EU |

G105 |

NC38(31/2IF) |

5(127.0) |

211/16(68.3) |

|

31/2(88.9) |

13.30 |

0.368(9.35) |

2.764(70.2) |

EU |

G105 |

*NC38(31/2IF) |

5(127.0) |

27/16(61.9) |

|

31/2(88.9) |

13.30 |

0.368(9.35) |

2.764(70.2) |

EU |

S135 |

NC38(31/2IF) |

43/4(120.7) |

29/16(65.1) |

|

31/2(88.9) |

13.30 |

0.368(9.35) |

2.764(70.2) |

EU |

S135 |

NC38(31/2IF) |

5(127.0) |

27/16(61.9) |

|

31/2(88.9) |

13.30 |

0.368(9.35) |

2.764(70.2) |

EU |

S135 |

*NC38(31/2IF) |

5(127.0) |

21/8(54.0) |

|

31/2(88.9) |

15.50 |

0.449(11.4) |

2.602(66.1) |

EU |

E75 |

NC38(31/2IF) |

43/4(120.7) |

211/16(68.3) |

|

31/2(88.9) |

15.50 |

0.449(11.4) |

2.602(66.1) |

EU |

E75 |

NC38(31/2IF) |

43/4(120.7) |

29/16(65.1) |

|

31/2(88.9) |

15.50 |

0.449(11.4) |

2.602(66.1) |

EU |

E75 |

*NC38(31/2IF) |

5(127.0) |

29/16(65.1) |

drillpipe

|

Size |

WeightDesignation |

CalculatedPlain-EndWeight |

OutsideDiameter |

Grade |

WallThickness |

UpsetEnds.ForWeld-onToolsJoint |

|||

|

Lb/ft |

kg/m |

in |

mm |

In |

mm |

||||

|

23/8 |

6.65 |

6.26 |

9.32 |

2.375 |

60.3 |

E,X,G,S |

0.280 |

7.11 |

EU |

|

27/8 |

10.40 |

9.72 |

14.48 |

2.875 |

73.0 |

E,X,G,S |

0.362 |

9.19 |

IUorEU |

|

31/2 |

9.50 |

8.81 |

13.12 |

3.500 |

88.9 |

E |

0.254 |

6.45 |

IUorEU |

|

31/2 |

13.30 |

12.31 |

18.34 |

3.500 |

88.9 |

E,X,G,S |

0.368 |

9.35 |

IUorEU |

|

31/2 |

15.50 |

14.63 |

21.79 |

3.500 |

88.9 |

E |

0.449 |

11.40 |

IUorEU |

|

31/2 |

15.50 |

14.63 |

21.79 |

3.500 |

88.9 |

X,G,S |

0.449 |

11.40 |

EUorIEU |

|

4 |

14.00 |

12.93 |

19.26 |

4.000 |

101.6 |

E,X,G,S |

0.330 |

8.38 |

IUorEU |

|

41/2 |

13.75 |

12.24 |

18.23 |

4.500 |

114.3 |

E |

0.271 |

6.88 |

IUorEU |

|

41/2 |

16.60 |

14.98 |

22.31 |

4.500 |

114.3 |

E,X,G,S |

0.337 |

8.56 |

EUorIEU |

|

41/2 |

20.00 |

18.69 |

27.84 |

4.500 |

114.3 |

E,X,G,S |

0.430 |

10.92 |

EUorIEU |

|

5 |

16.25 |

14.87 |

22.15 |

5.000 |

127.0 |

X,G,S |

0.296 |

7.52 |

IU |

|

5 |

19.50 |

17.93 |

26.71 |

5.000 |

127.0 |

E |

0.362 |

9.19 |

IEU |

|

5 |

19.50 |

17.93 |

26.71 |

5.000 |

127.0 |

X,G,S |

0.362 |

9.19 |

EUorIEU |

|

5 |

25.60 |

24.03 |

35.79 |

5.000 |

127.0 |

E |

0.500 |

12.70 |

IEU |

|

5 |

25.60 |

24.03 |

35.79 |

5.000 |

127.0 |

X,G,S |

0.500 |

12.70 |

EUorIEU |

|

51/2 |

21.90 |

19.81 |

29.51 |

5.500 |

139.7 |

E,X,G,S |

0.361 |

9.17 |

IEU |

|

51/2 |

24.70 |

22.54 |

33.57 |

5.500 |

139.7 |

E,X,G,S |

0.415 |

10.54 |

IEU |

|

65/8 |

25.20 |

22.19 |

33.05 |

6.625 |

168.3 |

E,X,G,S |

0.330 |

8.38 |

IEU |

|

65/8 |

27.70 |

24.21 |

36.06 |

6.625 |

168.3 |

E,X,G,S |

0.362 |

9.19 |

IEU |

|

Tensile |

||||||||

|

Group |

Grade |

YieldStrength |

TensileStrength |

Elongation,Min. |

||||

|

Minimum |

Maximum |

Minimum |

||||||

|

psi |

Mpa |

psi |

Mpa |

psi |

Mpa |

|||

|

1 |

E-75 |

75000 |

517 |

105000 |

724 |

100000 |

689 |

Seefootnotea |

|

3 |

X-95 |

95000 |

655 |

125000 |

862 |

105000 |

724 |

Seefootnotea |

|

G-105 |

105000 |

724 |

135000 |

931 |

115000 |

793 |

Seefootnotea |

|

|

S-135 |

135000 |

931 |

165000 |

1138 |

145000 |

1000 |

Seefootnotea |

|

Send product request

Other supplier products

| LT-T Type Releasing Overshot | The releasing overshot is the special external fishing tool used for fishing drilcollar ,drill pipe ,oil tube and other fishes in drilling and work... | |

| The LL Type Reverse Circulation Junk Basket | The LL type reverse circulation junk basket is used to retrieve all types of small junk objects such as cone,cutter,hand tool and junks from the bo... | |

| dril-collar | Non-magnetic Drill collars are made from Non-magnetic steel bars with low-strength by combining a proprietary chemical analysis and a rotary hammer... | |

| Integral Heavy Weight Drill Pipe | The wall thickness of heavy weight drill pipe is between drill pipe and drill collar, its structure is similar with drill pipe. It is made from pre... | |

| Integral drill pipe | Our company's drill pipes are in accordance with API 5D, API SPEC 7 Standards. Thematerial of drill pipe body are chosen by the 1&3 group of... |

Same products

| Embrace Intelligent Automation for Unmatched Box Production Efficiency | Seller: cenwan | 隆重推出我们的全自动智能高速折叠糊盒机,这是现代包装机械设计的巅峰之作。该设备融合了先进的机器人技术、智能传感技术和精密工程,可为各种瓦楞纸箱的生产提供真正的自动化体验。它旨在最大限度地提高产量... | |

| engraving machine | Seller: Hangzhou siseyin Technology Co., Ltd | Engraving machine from China, low price and high quality, the machine is very good | |

| Precision engraving machine | Seller: Hangzhou siseyin Technology Co., Ltd | Packaging machinery export trade service, delivering goods to Russia, Europe, professional custom... | |

| Efficient Film Cutting and UV Curing for Your Mobile Devices | Seller: Shenzhen Wikshu Technology Co. | Mechanic Auto X450 Intelligent Film Cutting and Laminating All in One Machine for Cutting Laminat... | |

| China Supplier Automatic Glass Bottle Juice Liquid Filling Machine for Beverage Plants | Seller: Professional Hebei Shenghui Pump Company | Thebeverage liquid filling machine is a ideal choice for precisely and quickly filling fluids wit... |