Wireless Transmission Pipe Ultrasonic Flaw Detector

The ultrasonic pipe testing equipmentsystem is suitable for the automatic detection of various internal and external defects of steel pipes. The principle of ultrasonic flaw detection is that after the ultrasonic wave is coupled into the steel pipe through water, the incident propagation will cause ultrasonic reflection when there is a defect in the pipe. The ultrasonic instrument will alarm the ultrasonic reflected signal after realizing the signal to realize the automatic detection of the defect; Transmission ultrasonic pipe testing equipmentis currently the advanced detection equipment in China.

Wireless Transmission Pipe Ultrasonic Flaw Detector Introduction

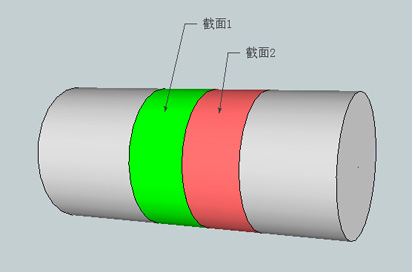

Rotating probe configuration

A total of 3 probe adjustment frames are placed on section 1 at 120°apart. Each of the adjustment frames is equipped with a 2-channel combined ultrasonic line focusing longitudinal probe to detect longitudinal defects of the steel tube in a clockwise direction.

Detection of defects: Vertical and vertical defects in the steel pipe are detected in a clockwise direction.

Center frequency: 5.0MHz±10%

Coupling method: water immersion method

Quantity: 3 sets of probes, each consisting of 2 wafers. These 3 sets of probes are evenly distributed in the circumferential direction of the workpiece, spaced 120° apart, on the same section. A total of 6 channels of water immersion probes.

A total 3 probe adjustment frames are placed on section2, separated by120°, and a 2-channel combined ultrasonic line focusing longitudinal probe is arranged on each adjustment frame to detect longitudinal defects of the steel pipe counterclockwise.

Detection of defects: counter-clockwise detection of longitudinal defects inside and outside the steel pipe.

the center frequency: 5.0MHz ± 10%

coupling method: water immersion method

Quantity: 3 sets of probes, each consisting of 2 wafers. These 2 sets of probes are evenly distributed in the circumferential direction of the workpiece, spaced 120° apart, on the same section. A total of 6 channels of water immersion probes.

Defect detection standard

Inspection of Longitudinal and Transverse Defects in Ultrasound Steel Pipe: GB/T5777-2008 L2(C5) Standard

Wireless Transmission Pipe Ultrasonic Flaw Detector Performance

|

Number of channels |

12channels |

|

Flaw detection speed |

40m/min |

|

Total gain |

100dB,step 0.5dB |

|

Working mode |

Single probe transmitting, receiving or dual probe transmitting and receiving separately |

|

Sensitivity margin |

≥50dB |

|

resolution |

≥26dB |

|

Dynamic range |

≥30dB |

|

Scanning range |

0~5000mm |

|

Frequency range |

|

|

Sampling range |

250MHz |

|

Repeat frequency |

Signal channel100Hz~4KHzadjustable |

|

Vertical linearity |

≤2% |

|

Horizontal linearity |

≤1% |

|

Detection method |

Full-wave, positive half-wave , negative half-wave |

|

Gate setting |

3 gates per channel, A and B are defect gates, and c is an Interface tracking gate |

|

Alarm indication |

Alarm color display and audible alarm for each channel A, B, C |

|

Delay alarm |

Two ways, Delay time0.1~10S, step 0.1Swaveform storage, the unlimited number for waveform playback, printing and report generation |

We are one of the best ultrasonic testing equipment suppliersand ultrasonic flaw detector manufacturers,we provide ultrasonic pipe inspection equipment,ut pipe testing,ultrasonic flaw detector machine,ultrasonic flaw detector probe,ndt testing machineand ndt testing,RFQ today.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current weld testingis the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. A... | |

| Application of Ndt Inspection Equipment | Ndt inspection equipmentis widely used in industry, such as nuclear industry, weapon manufacturing, machinery industry, shipbuilding, petrochemical... | |

| BKNET-101 Automatic Eddy Current Testing | The eddy current testing(BKNET-101) is a fully automated eddy current inspection system that uses large-scale imported integrated circuits combined... | |

| Portable Magnetic Flux Leakage Testing Equipment | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects... | |

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... |

Похожие товары

| XD-MAX Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |