Wireless Transmission Pipe Ultrasonic Flaw Detector

The ultrasonic pipe testing equipmentsystem is suitable for the automatic detection of various internal and external defects of steel pipes. The principle of ultrasonic flaw detection is that after the ultrasonic wave is coupled into the steel pipe through water, the incident propagation will cause ultrasonic reflection when there is a defect in the pipe. The ultrasonic instrument will alarm the ultrasonic reflected signal after realizing the signal to realize the automatic detection of the defect; Transmission ultrasonic pipe testing equipmentis currently the advanced detection equipment in China.

Wireless Transmission Pipe Ultrasonic Flaw Detector Introduction

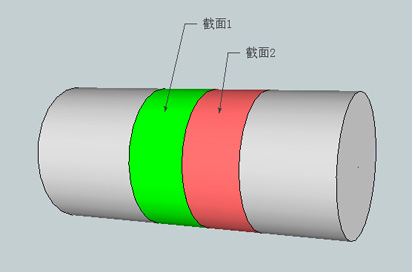

Rotating probe configuration

A total of 3 probe adjustment frames are placed on section 1 at 120°apart. Each of the adjustment frames is equipped with a 2-channel combined ultrasonic line focusing longitudinal probe to detect longitudinal defects of the steel tube in a clockwise direction.

Detection of defects: Vertical and vertical defects in the steel pipe are detected in a clockwise direction.

Center frequency: 5.0MHz±10%

Coupling method: water immersion method

Quantity: 3 sets of probes, each consisting of 2 wafers. These 3 sets of probes are evenly distributed in the circumferential direction of the workpiece, spaced 120° apart, on the same section. A total of 6 channels of water immersion probes.

A total 3 probe adjustment frames are placed on section2, separated by120°, and a 2-channel combined ultrasonic line focusing longitudinal probe is arranged on each adjustment frame to detect longitudinal defects of the steel pipe counterclockwise.

Detection of defects: counter-clockwise detection of longitudinal defects inside and outside the steel pipe.

the center frequency: 5.0MHz ± 10%

coupling method: water immersion method

Quantity: 3 sets of probes, each consisting of 2 wafers. These 2 sets of probes are evenly distributed in the circumferential direction of the workpiece, spaced 120° apart, on the same section. A total of 6 channels of water immersion probes.

Defect detection standard

Inspection of Longitudinal and Transverse Defects in Ultrasound Steel Pipe: GB/T5777-2008 L2(C5) Standard

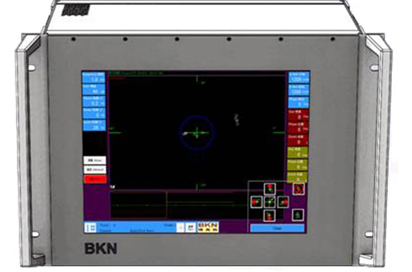

Wireless Transmission Pipe Ultrasonic Flaw Detector Performance

|

Number of channels |

12channels |

|

Flaw detection speed |

40m/min |

|

Total gain |

100dB,step 0.5dB |

|

Working mode |

Single probe transmitting, receiving or dual probe transmitting and receiving separately |

|

Sensitivity margin |

≥50dB |

|

resolution |

≥26dB |

|

Dynamic range |

≥30dB |

|

Scanning range |

0~5000mm |

|

Frequency range |

|

|

Sampling range |

250MHz |

|

Repeat frequency |

Signal channel100Hz~4KHzadjustable |

|

Vertical linearity |

≤2% |

|

Horizontal linearity |

≤1% |

|

Detection method |

Full-wave, positive half-wave , negative half-wave |

|

Gate setting |

3 gates per channel, A and B are defect gates, and c is an Interface tracking gate |

|

Alarm indication |

Alarm color display and audible alarm for each channel A, B, C |

|

Delay alarm |

Two ways, Delay time0.1~10S, step 0.1Swaveform storage, the unlimited number for waveform playback, printing and report generation |

We are one of the best ultrasonic testing equipment suppliersand ultrasonic flaw detector manufacturers,we provide ultrasonic pipe inspection equipment,ut pipe testing,ultrasonic flaw detector machine,ultrasonic flaw detector probe,ndt testing machineand ndt testing,RFQ today.

在线联系供应商

Other supplier products

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... | |

| Eddy Current Testing Equipment | There are two main types of ball studs: one is a combination of a spherical pin and an integral ball seat, and the other is a combination of a hemi... | |

| LGET-553 Aluminum Tube Eddy Current Flaw Detector | LGET-553 Aluminum Tube Eddy Current Flaw Detector Brief Introduction The aluminum tube is a type of non-ferrous metal which may have one or more... | |

| BKNFX Pre-Multi-Frequency Eddy Current Hardness Separator | Stimulating the coil makes a magnetic induction to the tested material. The induced electromotive force received by the testing coil is related to ... | |

| Eddy Current Testing Equipment for Tube, Bar and Wire | ECT Eddy current testing is a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals ... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | 卖方: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |