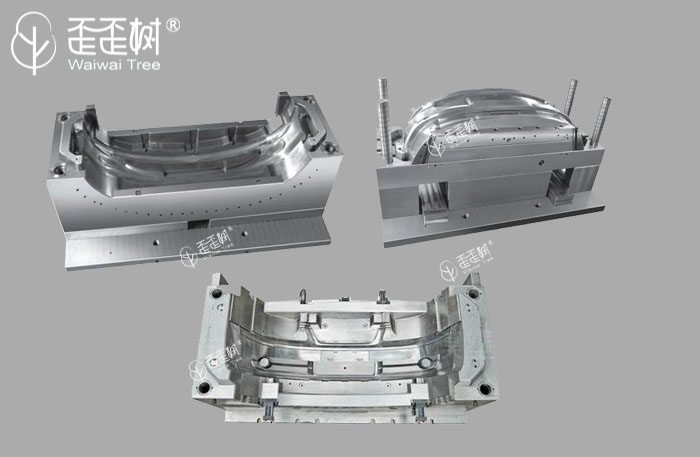

Development System of BMC Rotor Mould

At present, in the development process of BMC mold, the BMCcompositematerial is thermosetting resin. In the process of mold heating and curing, because of the expansion performance of BMC material, the pressure in the mold cavity suddenly increases, which makes it difficult to demould the BMC products, and the products are difficult to separate from the mold. Especially some products with long straight surface can not separate from the mold, resulting in die scrap and product development failure.

The BMC Rotor Mold can successfully complete the production process. Compared with the existing technology, it has the following advantages: there is a long straight surface product in the BMC rotor moulding, so it can not be separated from the mold, and it can be used when it can not set a large demoulding slope on the product surface. In the process of mold locking, the lock insert is locked up and down through the lock surface, so that the insert will have a fully fitted balance state, and the fit between the insert and the middle sleeve plate will leave a large space for fit clearance, which effectively prevents the die expansion during the injection molding process. When opening the die, the lock surface is removed and the insert is peeled off from the product quickly, so that the ejection production process can be completed smoothly and the stability of the whole die can be further improved.

If you want to know more details of bulk molding compound process, please visit our website.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

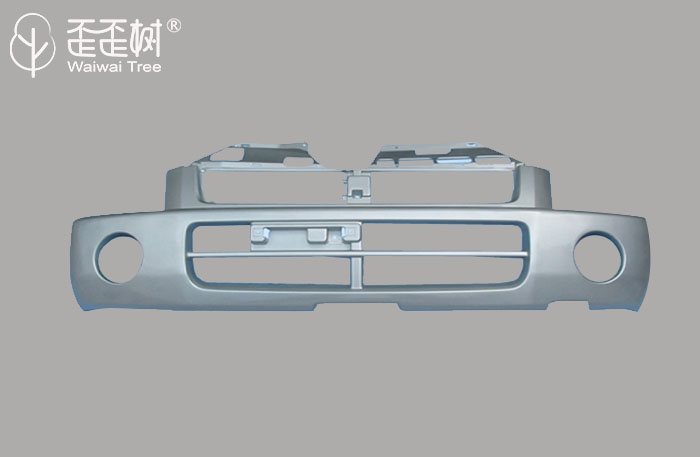

| Auto Parts Mould | BMC Auto PartsMould Automobiles are different in size and shape. That means automobile suppliers always need flexible auto parts molds, once there... | |

| Automotive Motor | BMC/SMC PRODUCTS BMC/SMC Motor Servo Motor Plastic-Envelop Motor Over Moulding Products BMC Rotor BMC Stator Air Conditioner Motor Refrigerator... | |

| BMC/SMC Molded Products | SMC, BMC thermosetting plastic products are produced by SMC and plastic smcmolding process. Types of BMC/SMC Molded Products BMC SMCMotor SM... | |

| SMC Automotive | SMC Car PartsDescription Parts made from sheet molding compound (SMC) are typically 25-35% lighter than steel parts and aluminum products of the s... | |

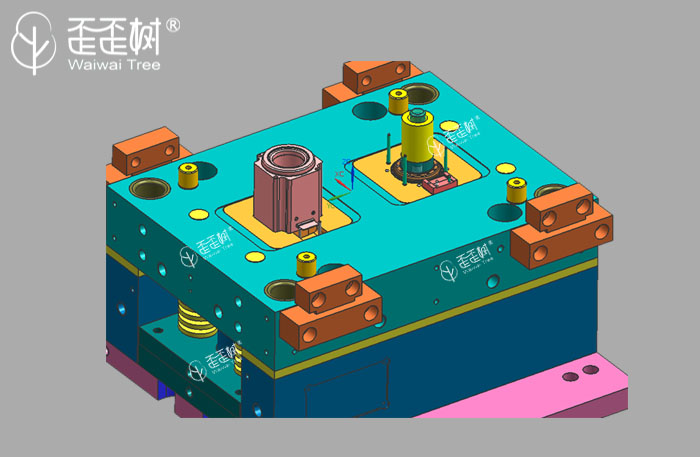

| Motor Mold | Motor MoldDescription Mainly for injection molding, the design of the runner and the parting surface should be as small as possible, and the cross... |

Похожие товары

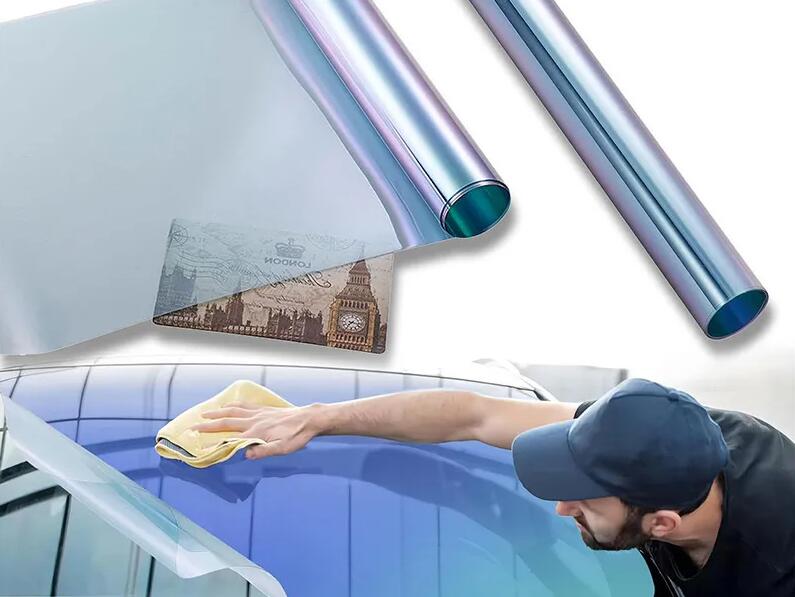

| Windshield Film | Продавец: Beijing Kingfilm Advanced Material Co., Ltd | Windshield Film The automotive windshield film is installed on the outside of the windshield and ... | |

| Metallized Window Tint | Продавец: Beijing Kingfilm Advanced Material Co., Ltd | Metallized Window Tint The multi-layer magnetron sputtering double silver series has the charact... | |

| Matte PPF | Продавец: Beijing Kingfilm Advanced Material Co., Ltd | Matte PPF Mattepaint protection filmhas the beauty of a matte finish and a better natural light.... | |

| Textured Film | Продавец: Beijing Kingfilm Advanced Material Co., Ltd | Textured Film The TexturePaint Protection Filmsnot only has the texture of carbon fibre, but als... | |

| Customizable Electric Tonneau Cover | Продавец: Guangzhou Zhenlonghui Auto Accessories Co., Ltd. | Customizable Electric Tonneau Cover The advanced all-electric retractable Tonneau cover gives yo... |